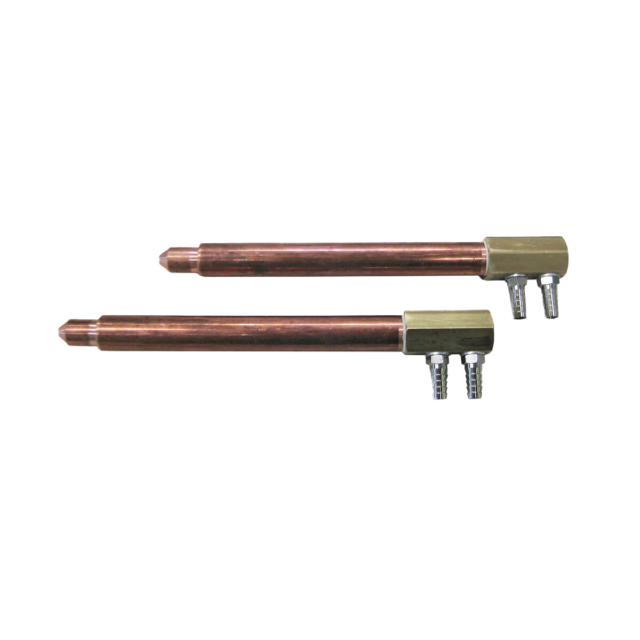

Set electrodeholders with electrodes

"*" indicates required fields

BSW bench welders, thanks to their reduced dimensions, are suitable to build customised multispot welding equipment. BSW 25 is particularly suitable for precision spot welding and, fitted with special accessories, can be used to weld small size parts. BSW 50 and 100, thanks to their rigid structure, allow high quality projection welding.

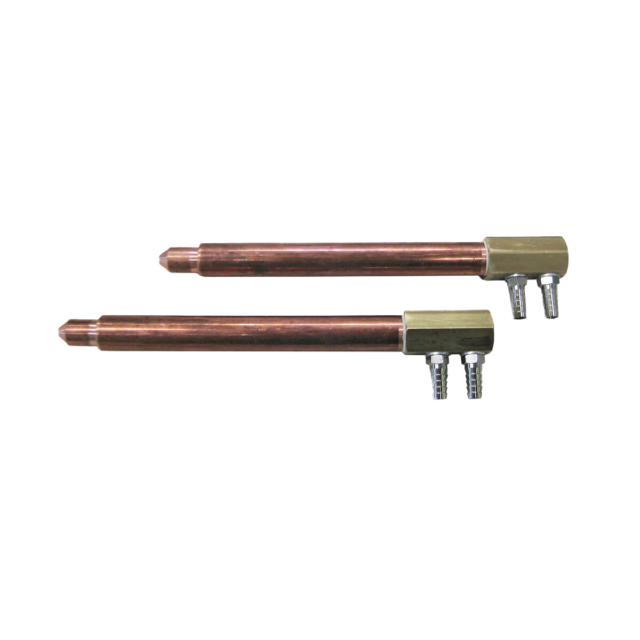

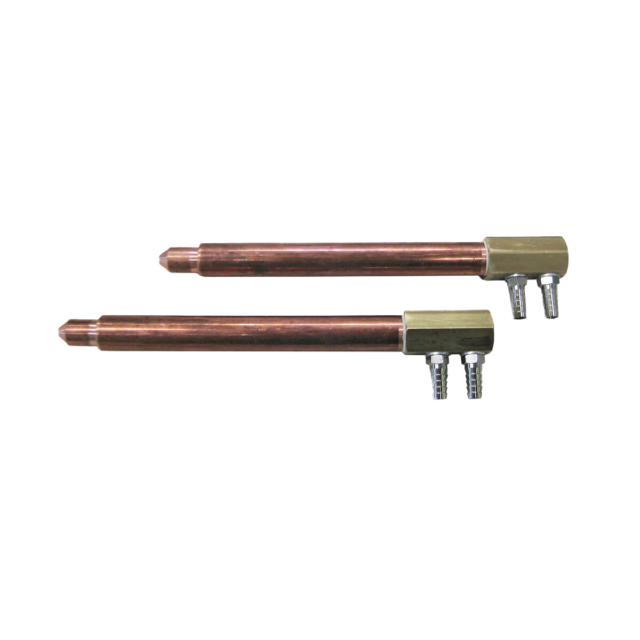

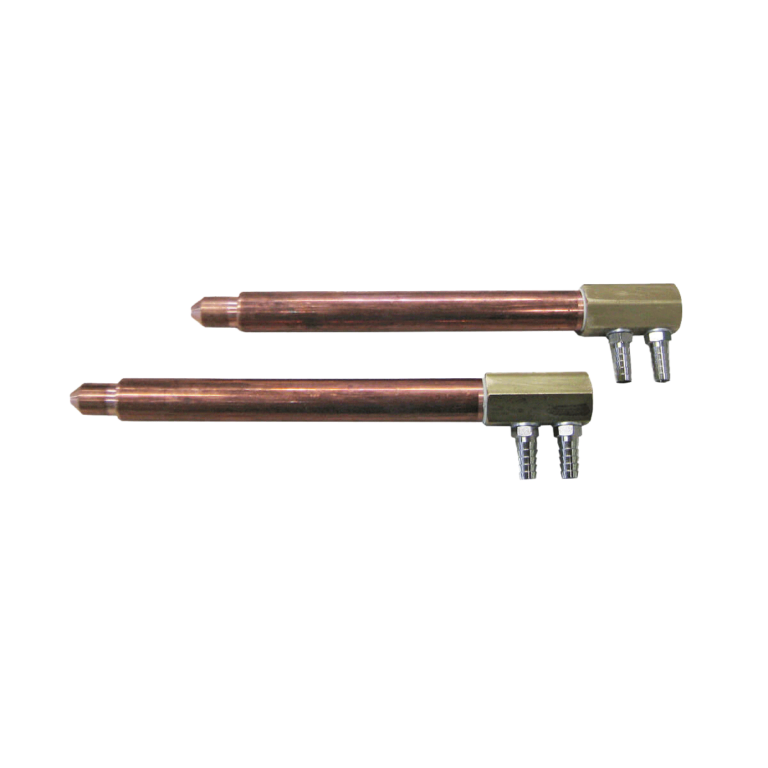

Set electrodeholders with electrodes

Set electrodeholders with electrodes

Set electrodeholders with electrodes

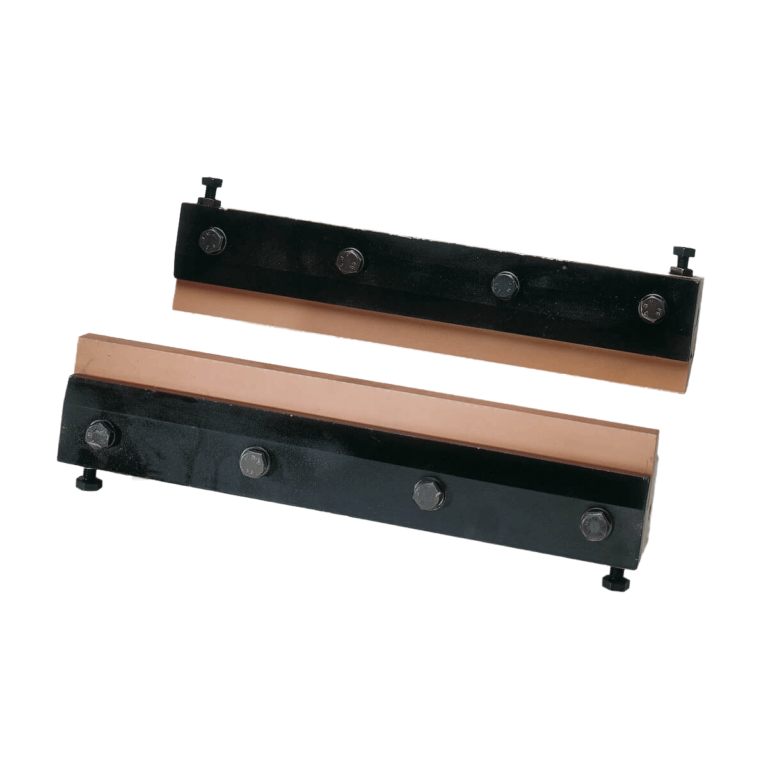

Set electrodeholder supports

Set electrodeholder supports

Set barholders with 400 mm bars

Set barholders with 600 mm bars

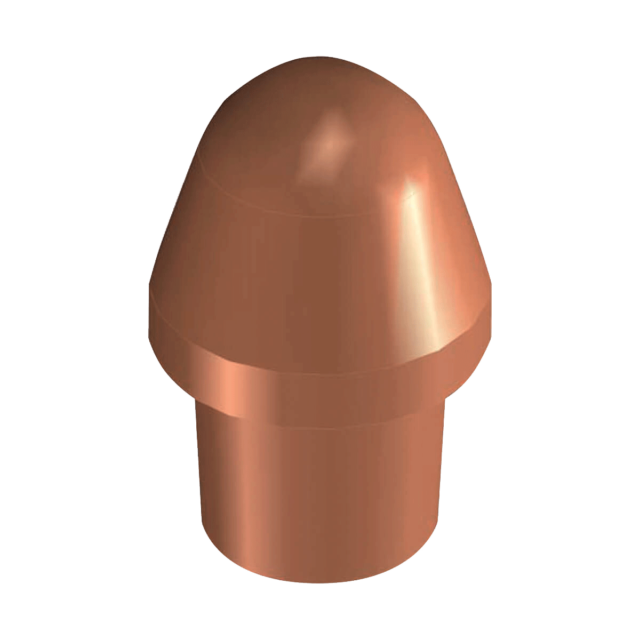

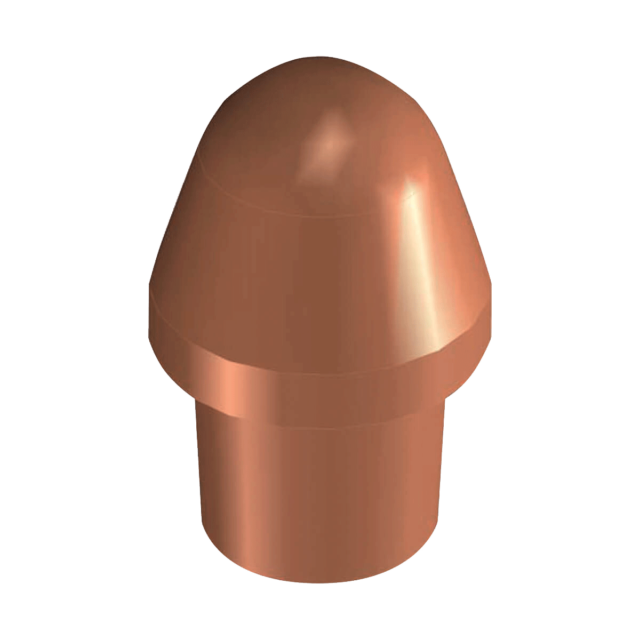

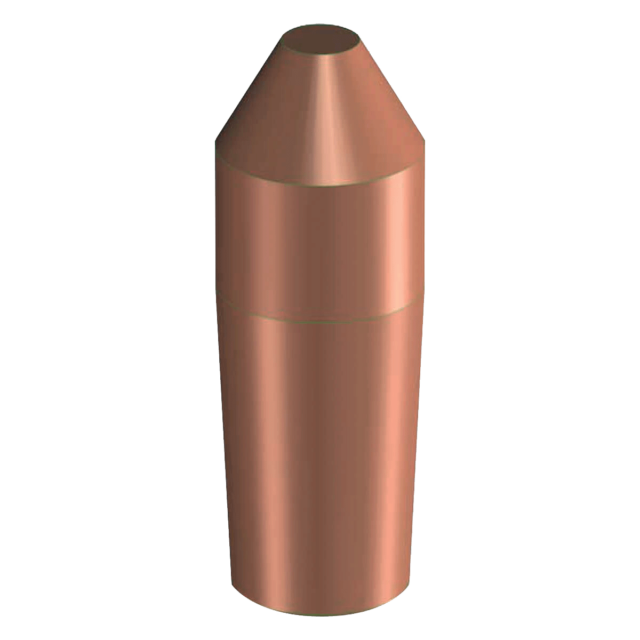

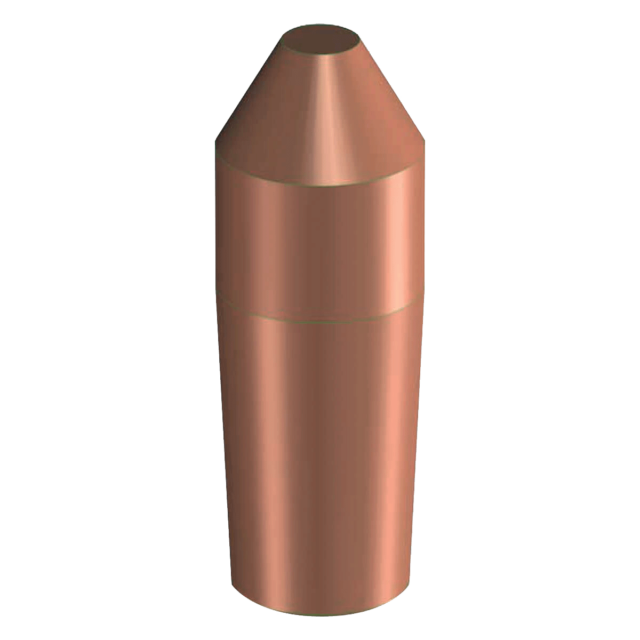

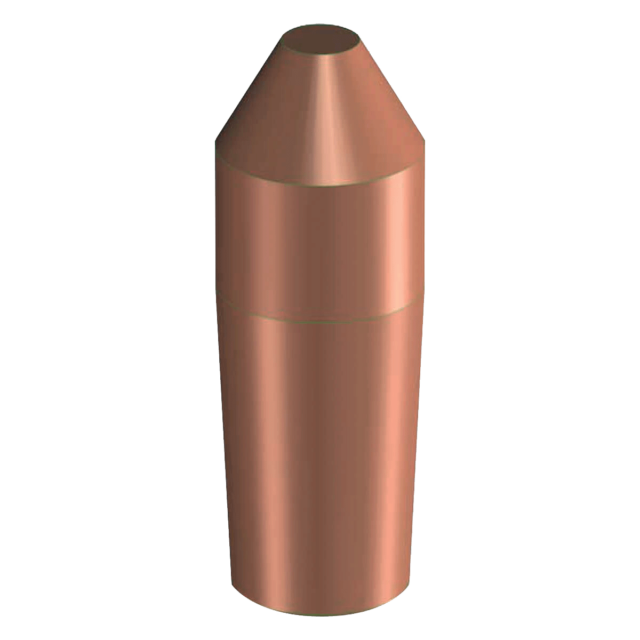

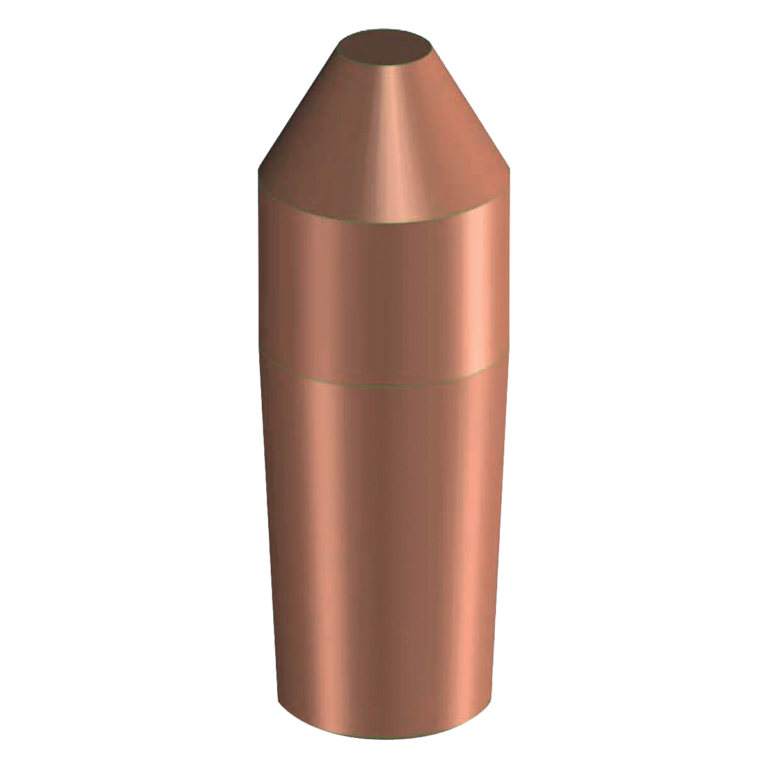

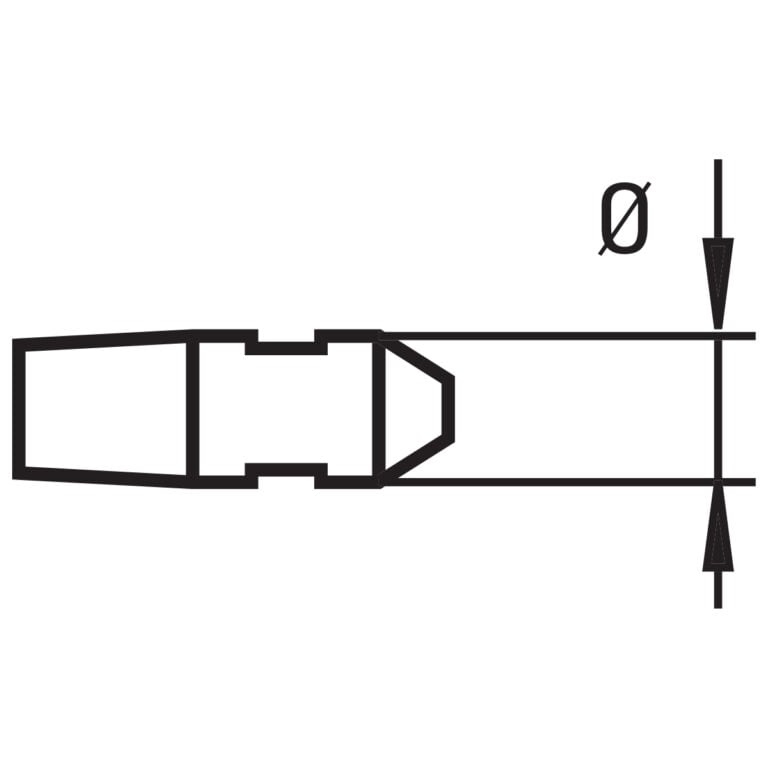

Set of 6 standard electrodes – Ø 16/12 mm

Set of 6 standard electrodes – Ø 16 mm

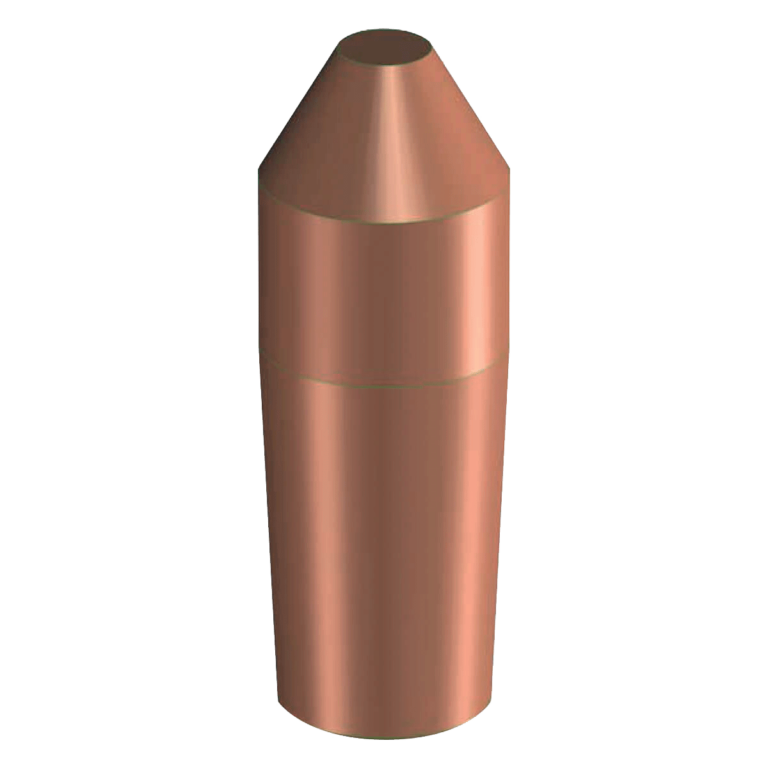

Set of 6 standard electrodes – Ø 19 mm

2 step pedal (1st step: squeeze, 2nd step: welding)

| TECHNICAL DATA | BSW 25 | BSW 50 | BSW 100 | |

| Single phase input 50/60 Hz | V | 400 | 400 | 400 |

| Rated power at 50% | kVA | 25 | 50 | 100 |

| Max. welding power | kVA | 52 | 128 | 331 |

| Installed power | kVA | 14 | 38 | 78 |

| Fuse(delayed action) | A | 40 | 100 | 200 |

| Secondary voltage | V | 3,7 | 5,5 | 9,4 |

| Secondary short circuit current | kA | 18 | 29 | 45 |

| Max welding current | kA | 14,4 | 23,2 | 36 |

| Work stroke | mm | 50 | 75 | 100 |

| Electrode force at 600kPa (6bar) | daN | 187 | 470 | 900 |

| Water consumption at 300 kPa (3bar) | l/min | 4 | 7 | 7 |

| Dimensions (LxWxH) | mm | 800 x 300 x 590 | 900 x 300 x 770 | 1080 x 325 x 1015 |

| Weight | kg | 96 | 210 | 380 |

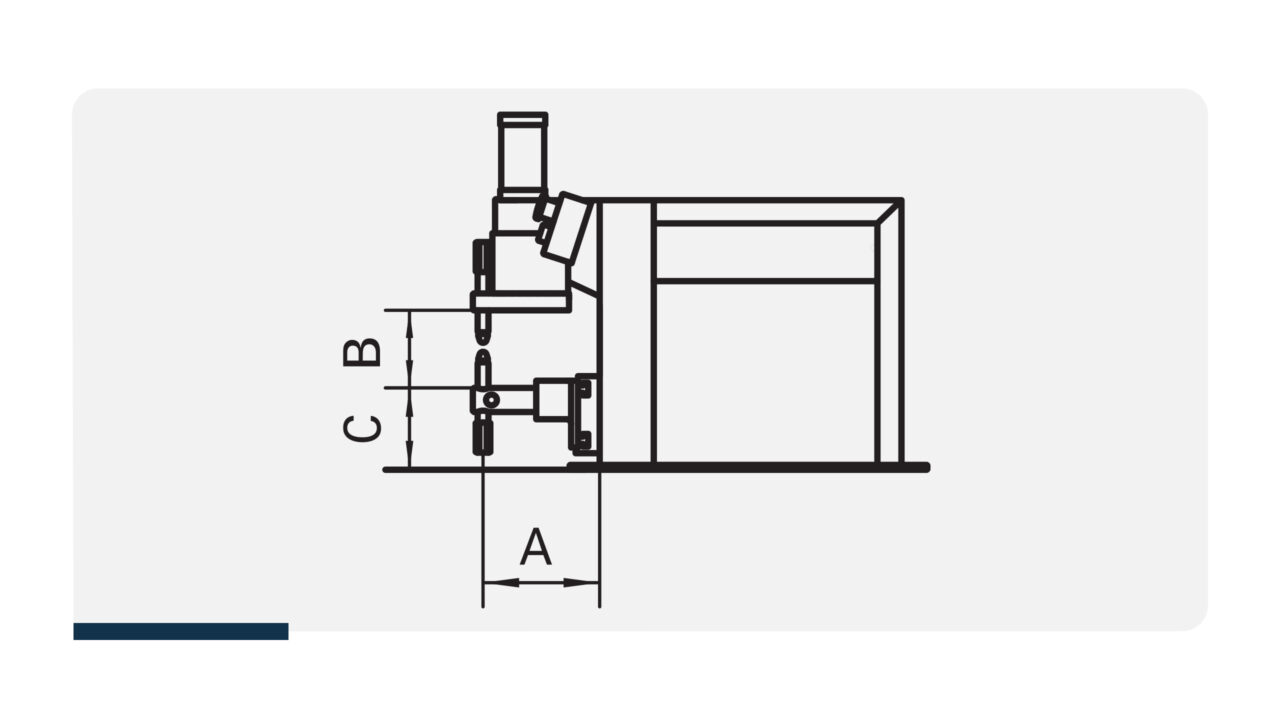

| BSW 25 | ||

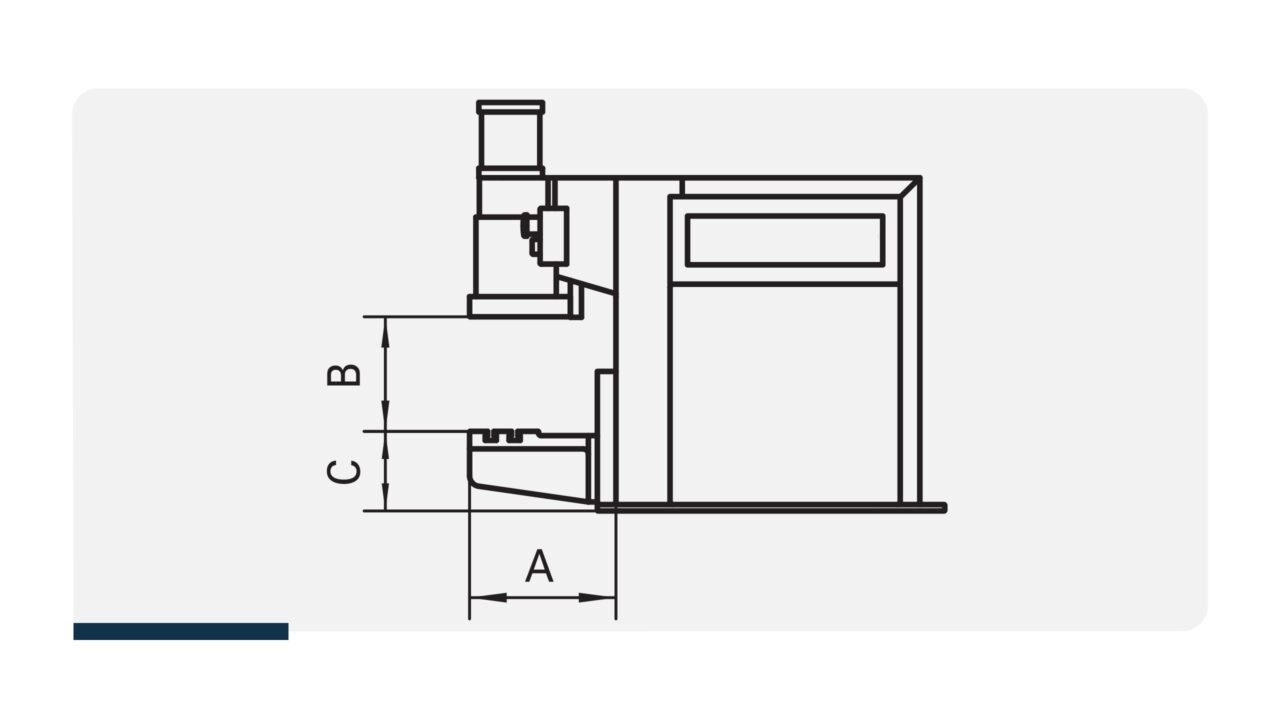

| A | mm | 192 |

| C – MAX. | mm | 129 |

| D – MAX. | mm | 136 |

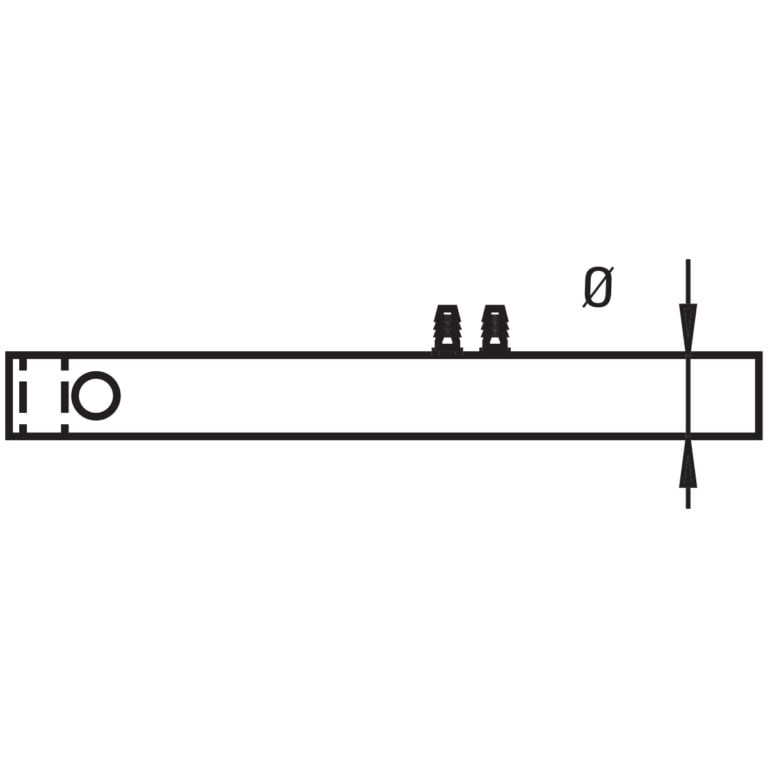

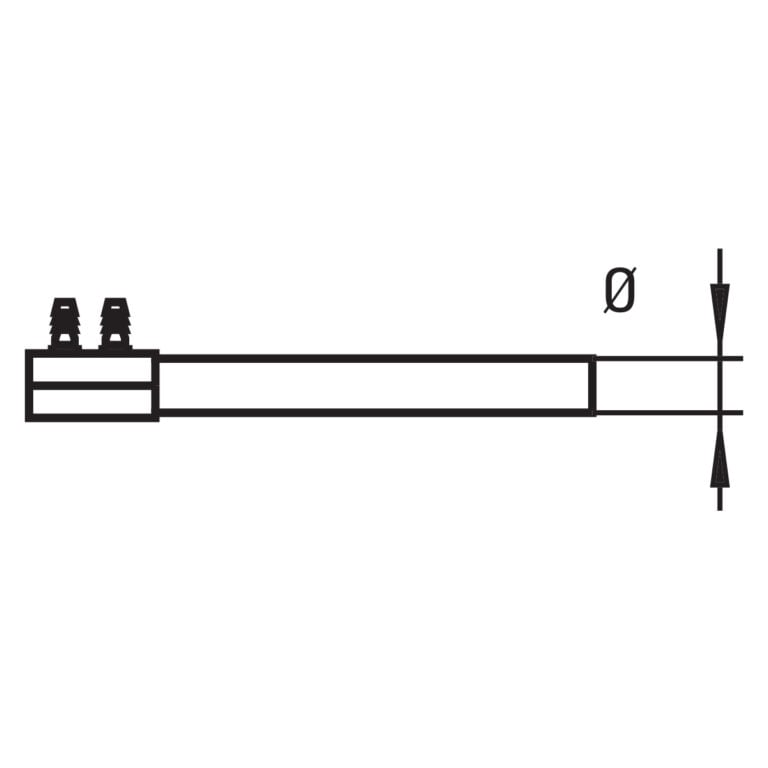

| Ø mm | 40 |

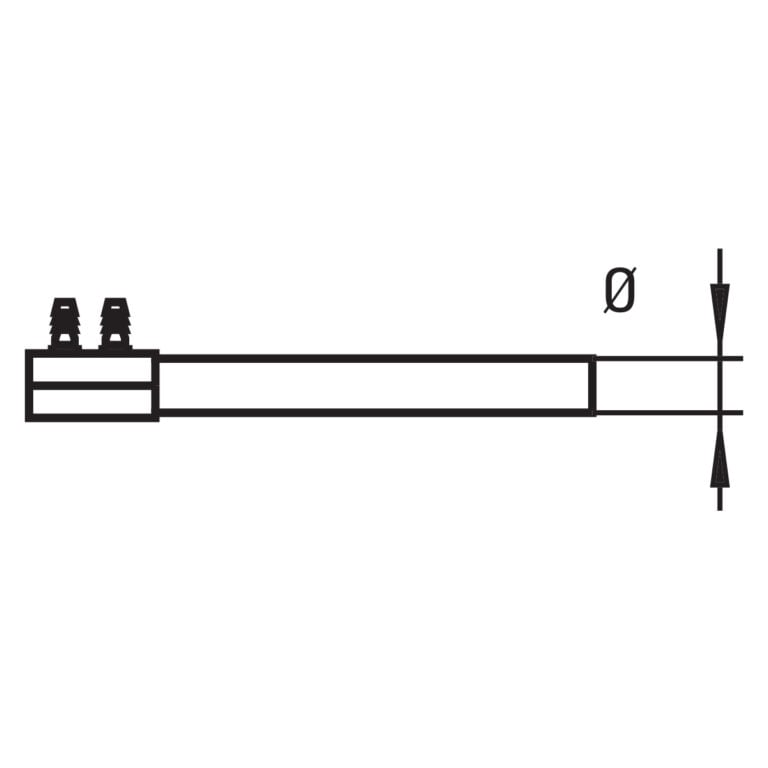

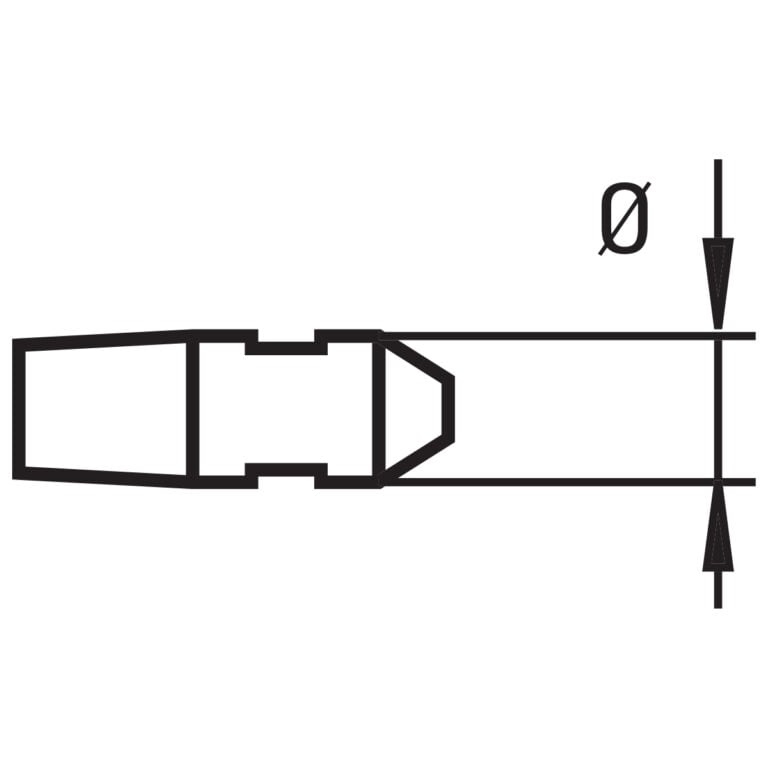

| Ø mm | 18 |

| Ø mm | 16 |

| BSW 50 | BSW 100 | ||

| A | mm | 276 | 335 |

| B | mm | 301 | 370 |

| C – MIN. | mm | 100 | 130 |

| C – MAX. | mm | 225 | 300 |

| D – MIN. | mm | 140 | 163 |

| D – MAX. | mm | 265 | 334 |

| BSW 50 | BSW 100 | ||

| Ø mm | 25 | 30 |

| Ø mm | 16 | 19 |

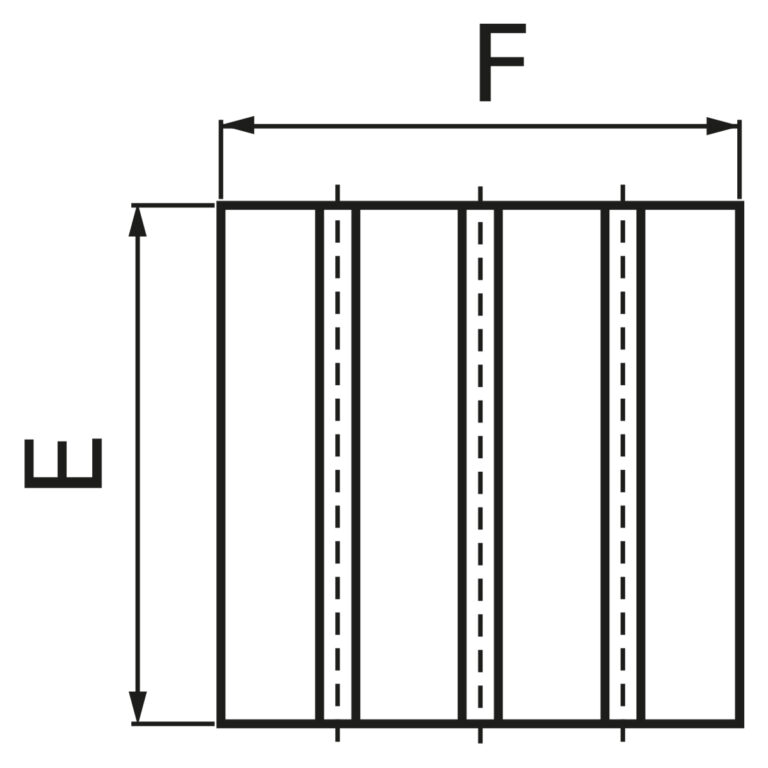

| E mm | 90 | 150 |

| F mm | 130 | 150 | |

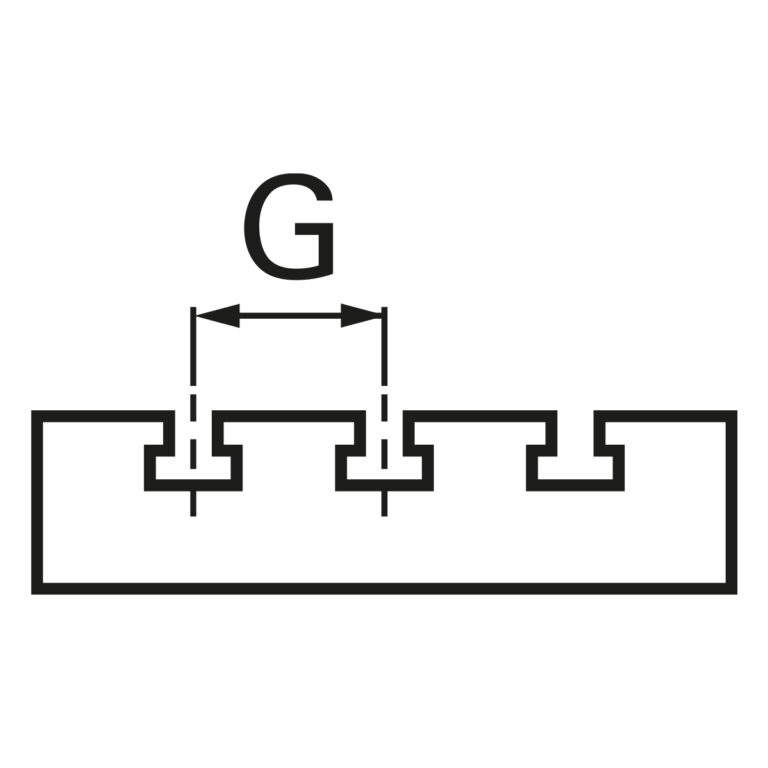

| G mm | 45 | 63 |

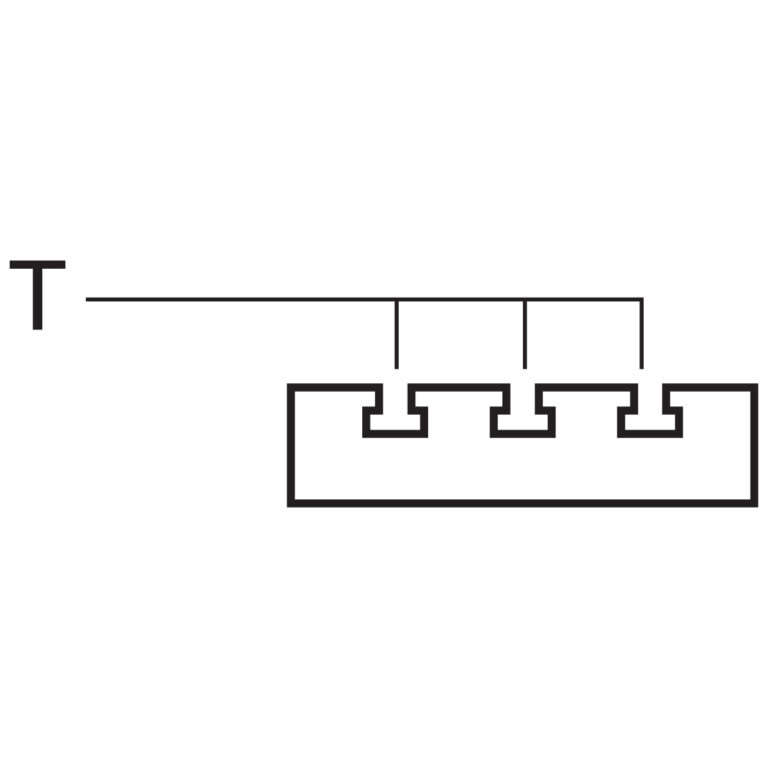

| T | 2 | 2 |