CEA

Welding together

Welding together since 1950

PROUD OF OUR HISTORY

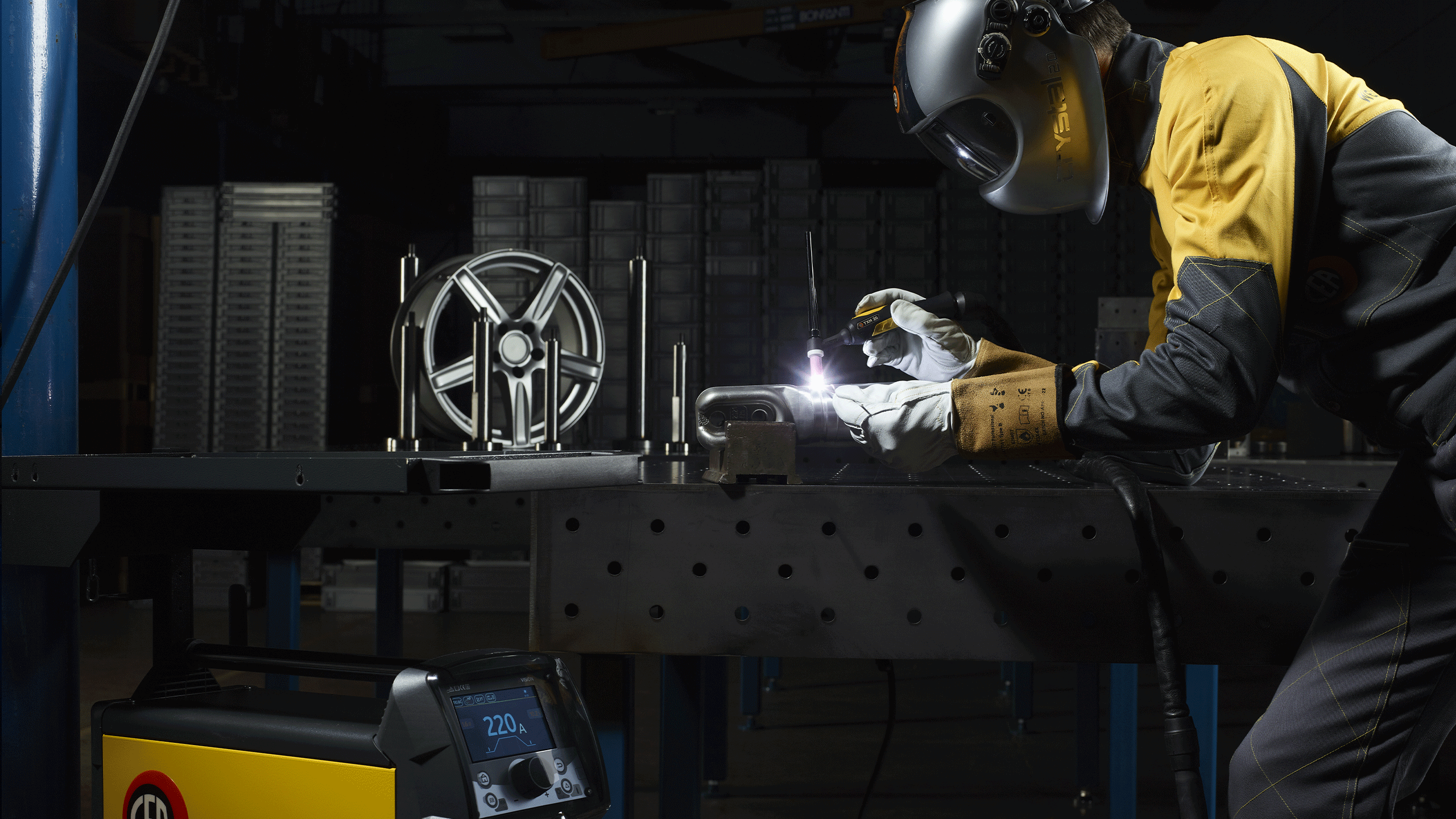

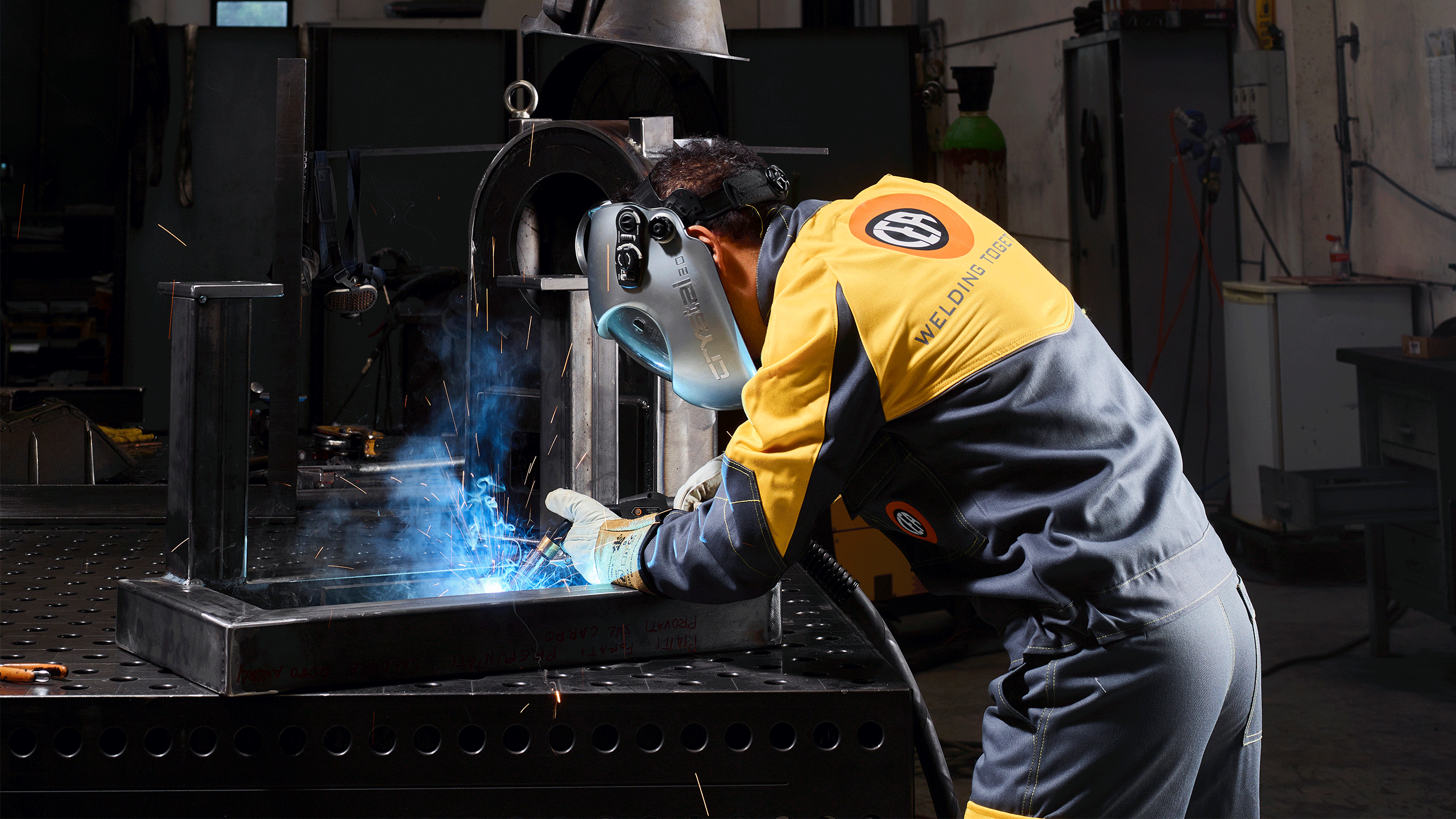

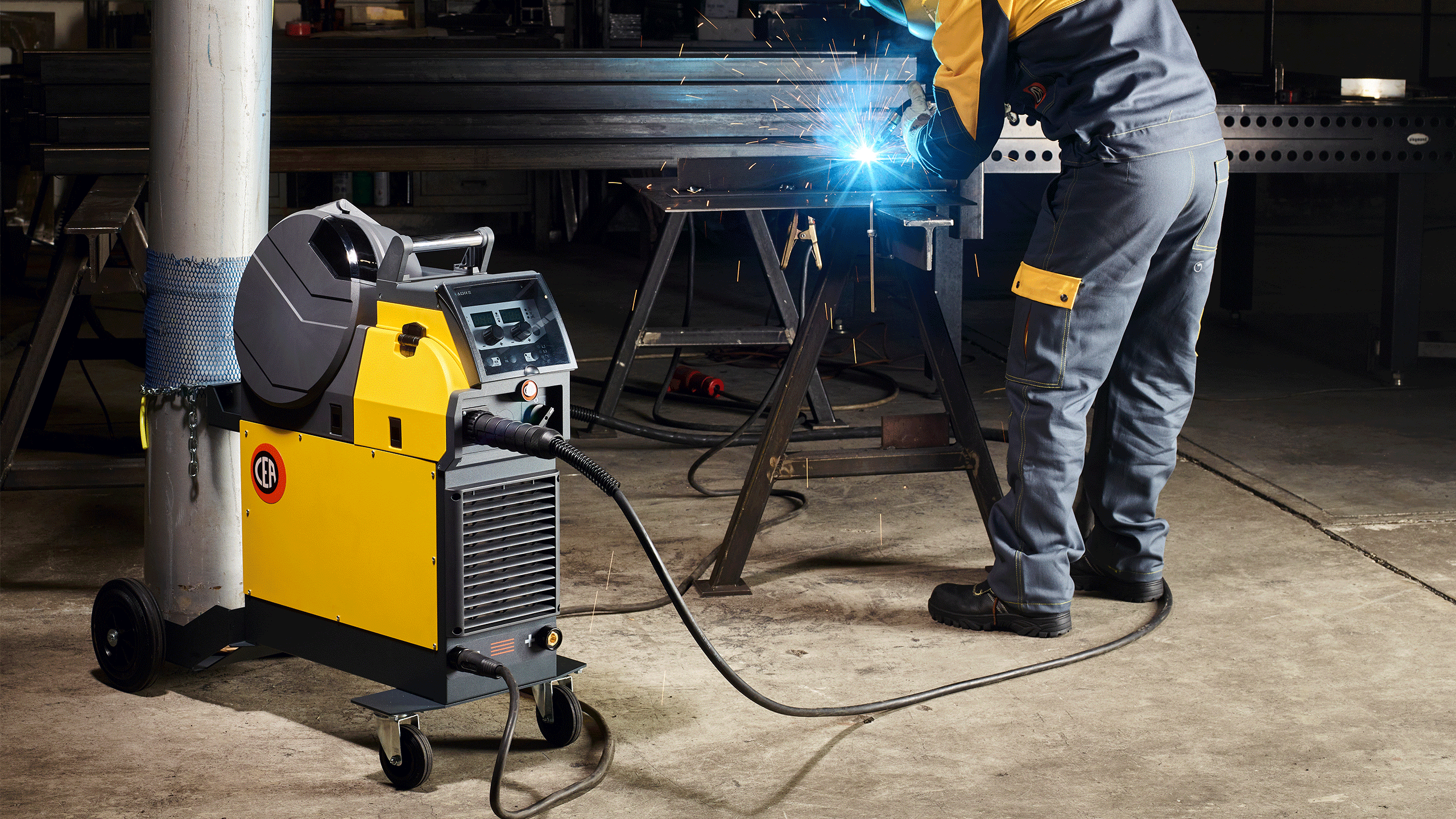

CEA, founded by Ezio Annettoni in 1950, is one of the worldwide leaders for the design and manufacture of Arc and Resistance welding machines and Plasma cutting equipment for the industrial market.

CEA is WELDING TOGETHER. Our mission is to stand side by side our customers, offering the best solutions to their needs in every moment by providing innovative welding and cutting equipment with excellent performances and an outstanding and functional design.

We believe that a sustainable approach with care for the environment and the people that work and weld with us always ensures a better product.

A Global presence

In over 100 countries

In over 70 years of history, CEA has built long lasting relationships with distributors and service centres in over 100 countries to satisfy the needs of all markets. CEA’s service centres are highly qualified and constantly updated to ensure a prompt and efficient after sale service.

Always ahead for

Innovation and Technology

Unique for its extensive range, CEA is always ahead in technological innovation, being large resources constantly invested in research and development. Excellent welding characteristics, continuous innovation, reliability, design and care for the industry‘s needs are the secrets of CEA’s growing worldwide success.

CEA's choice for

A sustainable future

CEA GOES GREEN is not a mere slogan, but the hallmark that highlights the goal to create value for our customers through sustainable and innovative products. Throughout its history, CEA has always put effort to reduce the environmental footprint of its activities and products thanks to the implementation of strategies to promote promote a more sustainable development.

- Focus on high-efficiency welding processes

- Renewable sources to produce electricity

- Eco-sustainable technologies for industrial production

- Use of recycled materials

CARBON NEUTRAL

Thanks to investments in renewable sources, CEA is on the path to become carbon neutral; a goal that is partly already been achieved. A photovoltaic system of 350 kWp allows us to produce energy annually for 320 MWh, a value higher than our internal energy consumption, making CEA self-sufficient from an electric energy standpoint.

HIGH EFFICIENCY TECHNOLOGY

The latest generation inverter technology and the development of new arc control software allows us to offer products with efficiencies that fully meet the energy-saving requirements of the ECODESIGN directive. In particular, the use of the new special welding processes “vision.“ enables welding to be carried out more quickly with lower heat input than traditional processes, guaranteeing energy savings often not considered.

CEA GOES GREEN identifies CEA products that meet our sustainability standards.

- Energy-efficient products

- Compliance with regulations for environmental protection.

- Care in the choice of components

- Use of paints with low environmental impact

- Low weights and dimensions for low shipping, disposal and recycling costs

- Use of recycled or recyclable material in all our packaging systems

High quality standards

Certifications

CEA has its quality management system ISO 9001 certified since 1994.

All CEA products are CE and UKCA marked, therefore compliant with all EU Directives and Standards. In particular CE marking implies the

conformity to the following main Directives:

- 2014/35/EU (LVD)

- 2014/30/EU (EMC) - (CISPR 11) A Class.

- 2011/65/EU (RoHS)

- 2009/125/EU (Eco-Design)

CEA products have been designed and built according to the following harmonized standards:

- IEC 60974-1 EN 60974-1 Welding power sources.

- IEC 60974-2 EN 60974-2 Liquid cooling systems.

- IEC 60974-3 EN 60974-3 Arc striking and stabilizing devices.

- IEC 60974-5 EN 60974-5 Wire feeders.

- IEC 60974-7 EN 60974-7 Torches.

- IEC 60974-10 EN 60974-10 Electromagnetic compatibility (EMC).

Something more about

Our History

1936: first steps in welding

CEA’s origin dates back to 1936 when Alessandro Annettoni, an expert creative electrician, together with his son Ezio started to build workmanlike electric welding equipment.

1950

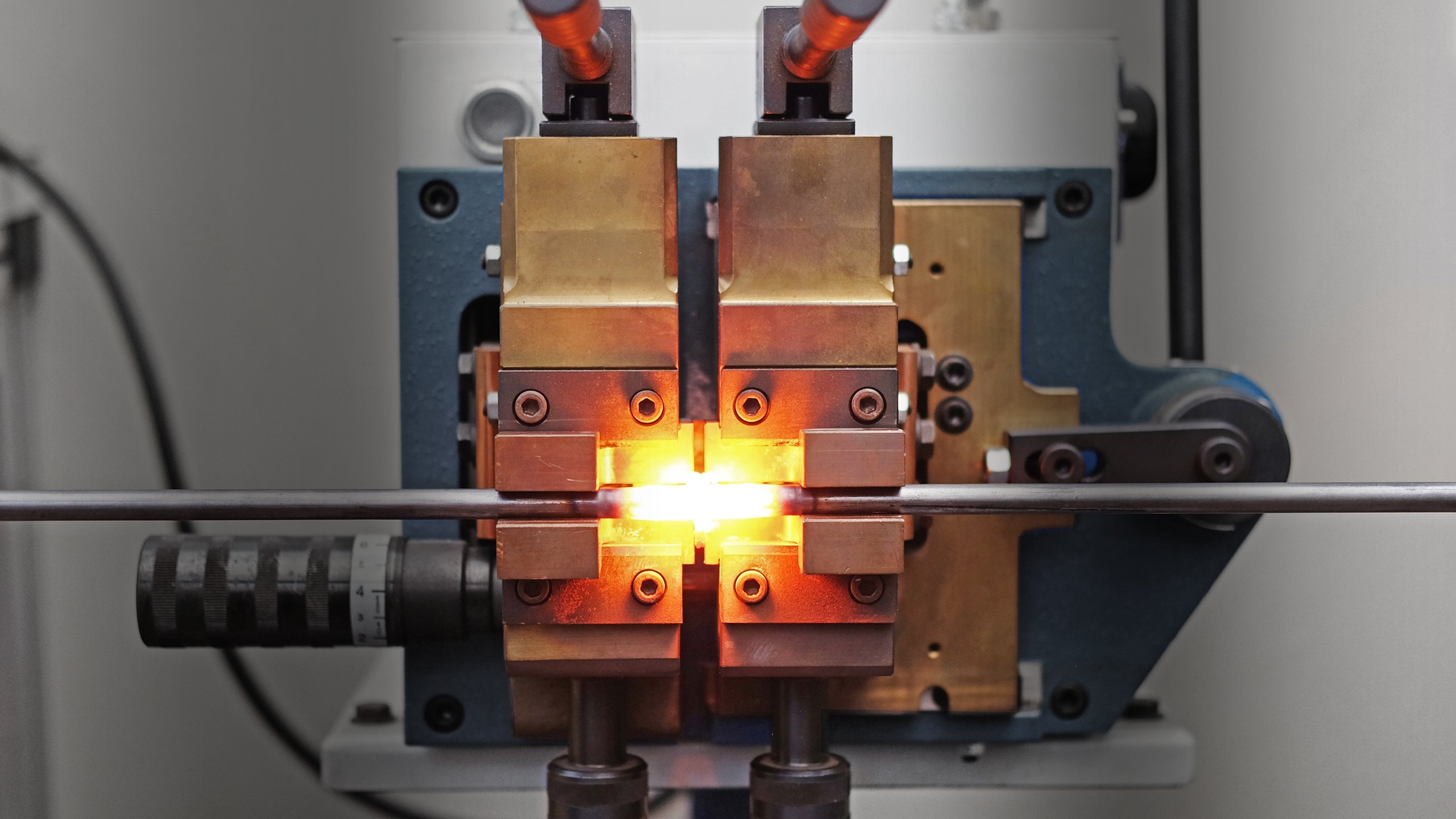

Ezio Annettoni established CEA, Costruzioni Elettromeccaniche Annettoni S.p.A., setting up a factory in Lecco, via G.B. Vico. The production range, including arc welders and resistance spot and butt welding equipment, already contained in essence many of the future concepts which CEA would introduce the following years innovation, quality components, accurate and purpose-built assembly, reliability and keen attention to quality/price ratio.

1953

1954

Only a few years after the Company’s settlement in via G.B. Vico, due to necessary expansion, CEA began construction at part of the present location in Corso Emanuele Filiberto.

1956

In 1956 came the welcome introduction of the new SELEN model – a DC static welder with three phase transformer and selenium rectifier. This was an important technological breakthrough to solve noise and frequent need of maintenance typical of the rotary machines built in 1953.

1959

By the end of the 1950’s, CEA recognized the huge potential of exporting. An outstanding export sales activity was started together with an adequate promotional campaign with a participation to the main worldwide exhibitions.

1962

CEA’s growth continued and a larger facility was again required. This further factory expansion provided a better production environment together with a vast and well assorted warehouse, able to quickly satisfy the needs of the worldwide distributors.

1969

A milestone in CEA history marking an outstanding progress in quality. Ezio Annettoni signed in the United States an agreement with P/H Chemetron of Chicago, which allowed him to build under licence MIG/MAG welding equipment for worldwide distribution. Such extremely high quality product, incorporating a top level innovative technology already worldwide known and appreciated, significantly opened the doors to a huge market in a promising further expansion.

1977

CEA’s aim was to satisfy a wider scope of its customers’ needs, which led to a steady effort in broadening the range. TIG welding power source production started.

1980

A further range expansion with the introduction of a new series of thyristor controlled electronic adjustment arc welders.

1982

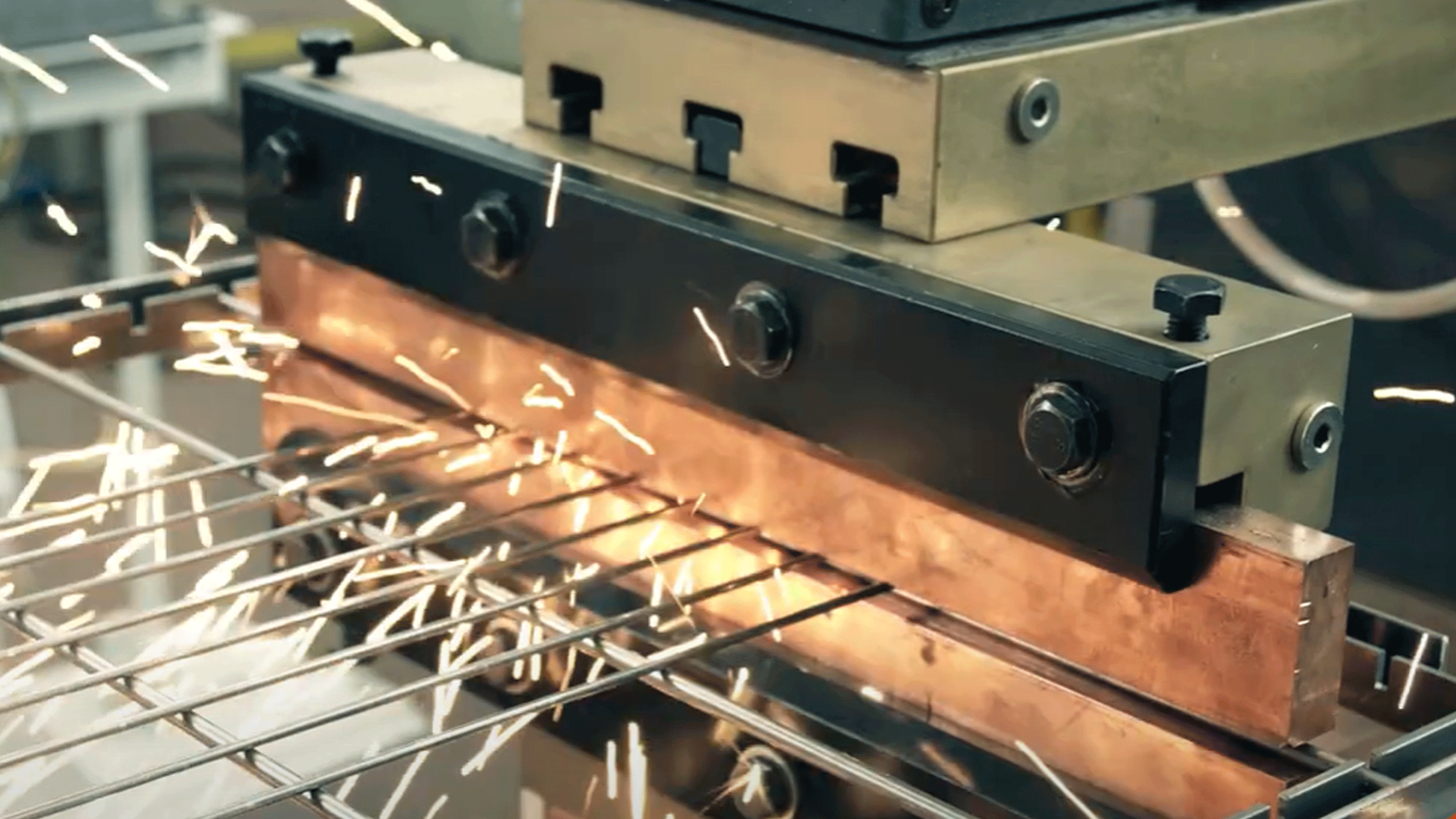

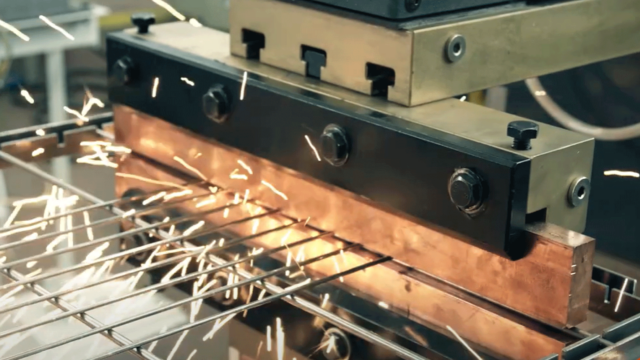

The keen attention to market demand led CEA to complete the range of resistance machines with a new series of three phase DC output welding equipment. Such new products were capable of guaranteeing high quality performances with far lower energy consumption than traditional ones.

1987

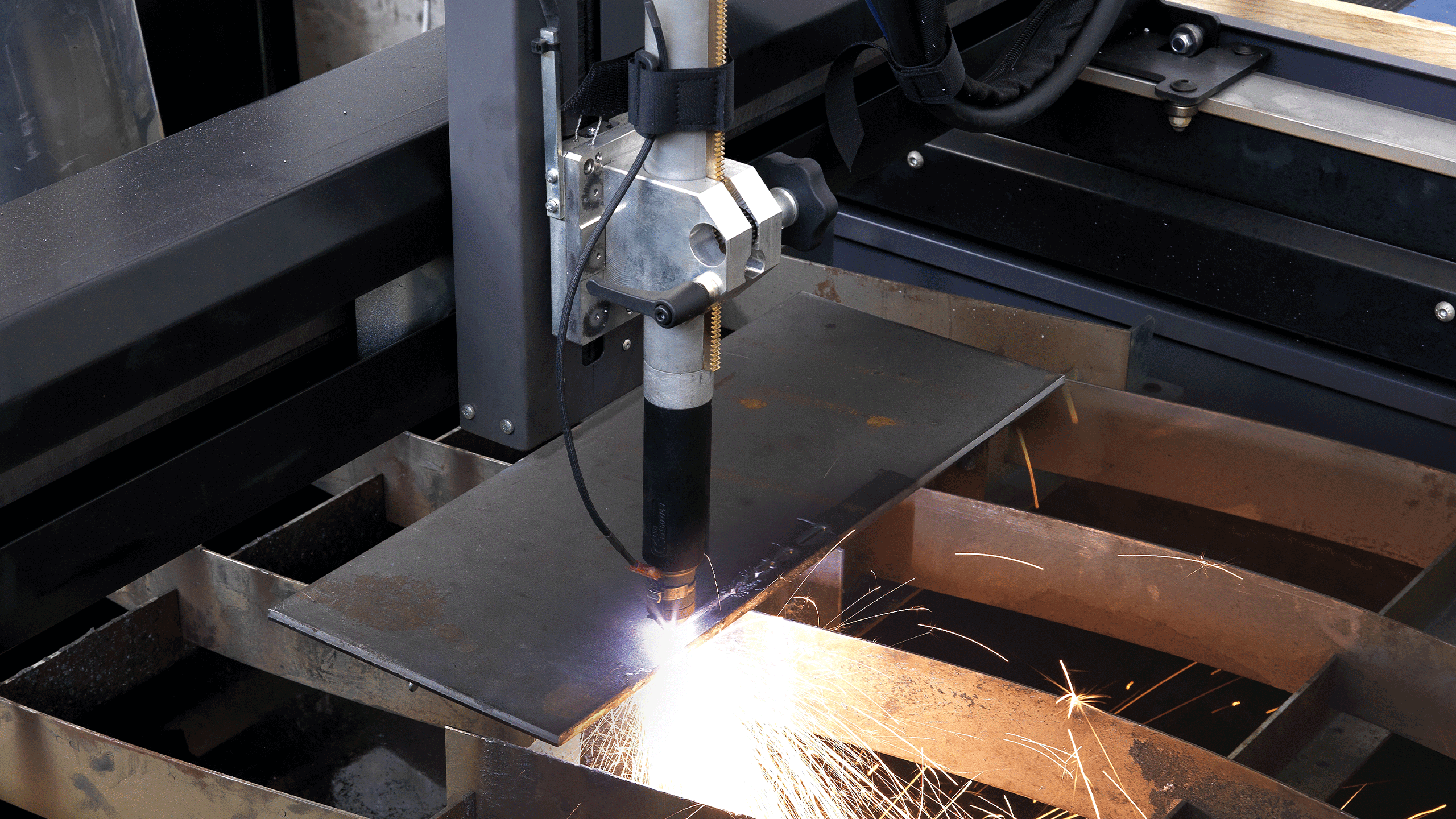

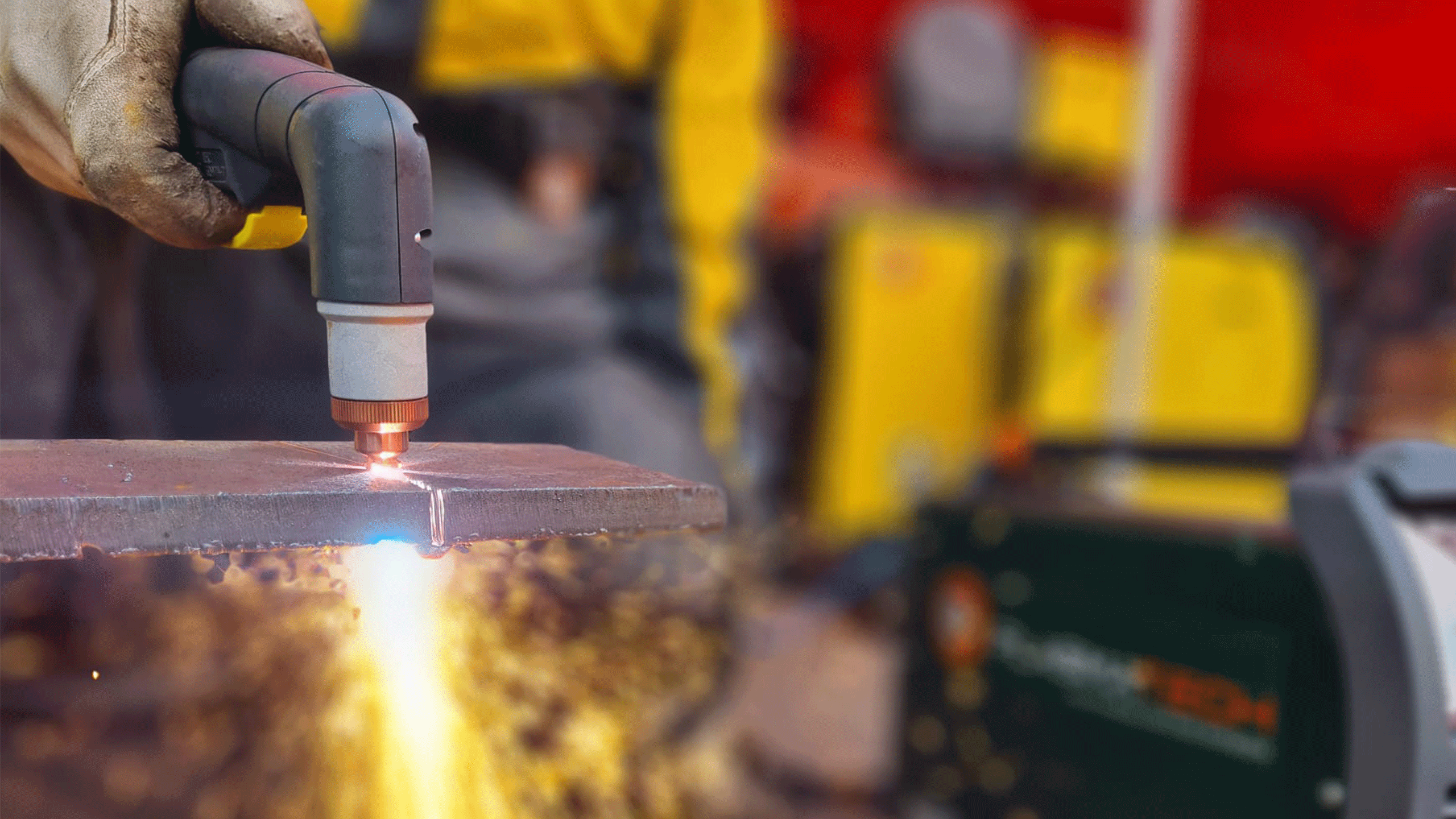

The industrial need of cutting in a quicker, easier and safer way, besides carbon steel, also noble metals such as stainless steel and aluminium, instigated the development of a totally new CEA line with the introduction of plasma cutting equipment.

1991

CEA’s constant dedication to research led the introduction into the CEA range of the first IGBT inverter welding machine, new technology which will be brought forward and integrated in the coming years into the whole arc and resistance range. CEA range growth continued with the introduction of the first synergic adjustment, microprocessor controlled, pulsed MIG/MAG machine.

1994

CEA, first among the italian welding equipment manufacturers, on 29th June 1994 reached the ISO 9001 quality system certification.

2000

CEA range was enriched by new path breaking design high technology RAINBOW range machines for MMA and TIG, among which RAINBOW 150, 150 A in 4 Kg only, an innovative MMA product, equipped with 100 KHz IGBT inverter. Thanks to its innovative and attractive design, RAINBOW 150 was included into the restricted and prestigious list of products that, after the XIX°COMPASSO D’ORO ADI Exhibition held in Milan, are being shown in the permanent exhibition collection. Quality, welding performance, manufacturing care and also aesthetics are the new CEA project philosophy which will be reflected in all new machines coming after the “revolutionary” innovative chassis of the Rainbow range.

2003

CEA has launched in this and subsequent year innovative design digital inverter novelties among which Multifunction “Dual Pulsed Mig” synergic DIGITECH 300, 400 and 500 and AC/DC Tig MATRIX series, technologically advanced, which allow high precision and repeatability of the achieved results. Fully digital controlled, they grant premium welding quality on all materials and particularly on aluminium and stainless steel. Resistance welding range was renewed thanks to new Medium Frequency inverter MF models (1000 Hz) also utilized in the VOYAGER range, CNC robotized systems working on more axis, the best reply to latest market need for quality, flexibility and high level welding performance.

2005

Range design renovation was completed by launching new COMPACT, MAXI and ECHO Mig’s, new PLASMA PLUS and PLASMA CUT equipment and, last but not least, the new Multifunction DIGISTAR 250, judged a “star performer” in the automotive industry due to its excellent welding joints mostly on aluminium and galvanized steel.

2009

In ESSEN 2009 CEA has launched a great number of modern design, technologically ahead, easy-to-use power sources, result of 60 years’ experience in the welding field, such as the new 1ph MATRIX 2200 range fitted with PFC, MATRIX 2700 and 420 range, CONVEX BASIC and VISION ranges and 1 ph TREO 1600 portable multifunction and others as shown in CEA website. We draw yr attention on the new fully colour display CONVEX VISION MIG/MAG multifunction synergic range, which, thanks to the innovative VISION.ARC software, fully meets the needs of combining synergy with the total control of the welding parameters in a user friendly way as requested by the clients, because total customer satisfaction is a must for CEA as it has been in 60 years of activity in “welding together”.

2013

Top performance MIG/MAG arc control software:

- vision.PIPE for first root pass and open gap

- vision.COLD for low heat transfer

- vision.ULTRASPEED for increased welding speed

- vision.POWER for high penetration

2016

CEA decides to give the right commercial importance to two ranges of products that have always been in the company production. For this reason the CEA PLASMATECH and CEA RESTECH division brands are born in order to further specialize their respective ranges and to refer to the experts of these specific markets with the awareness of being able to compare with the most qualified competitors.

2017

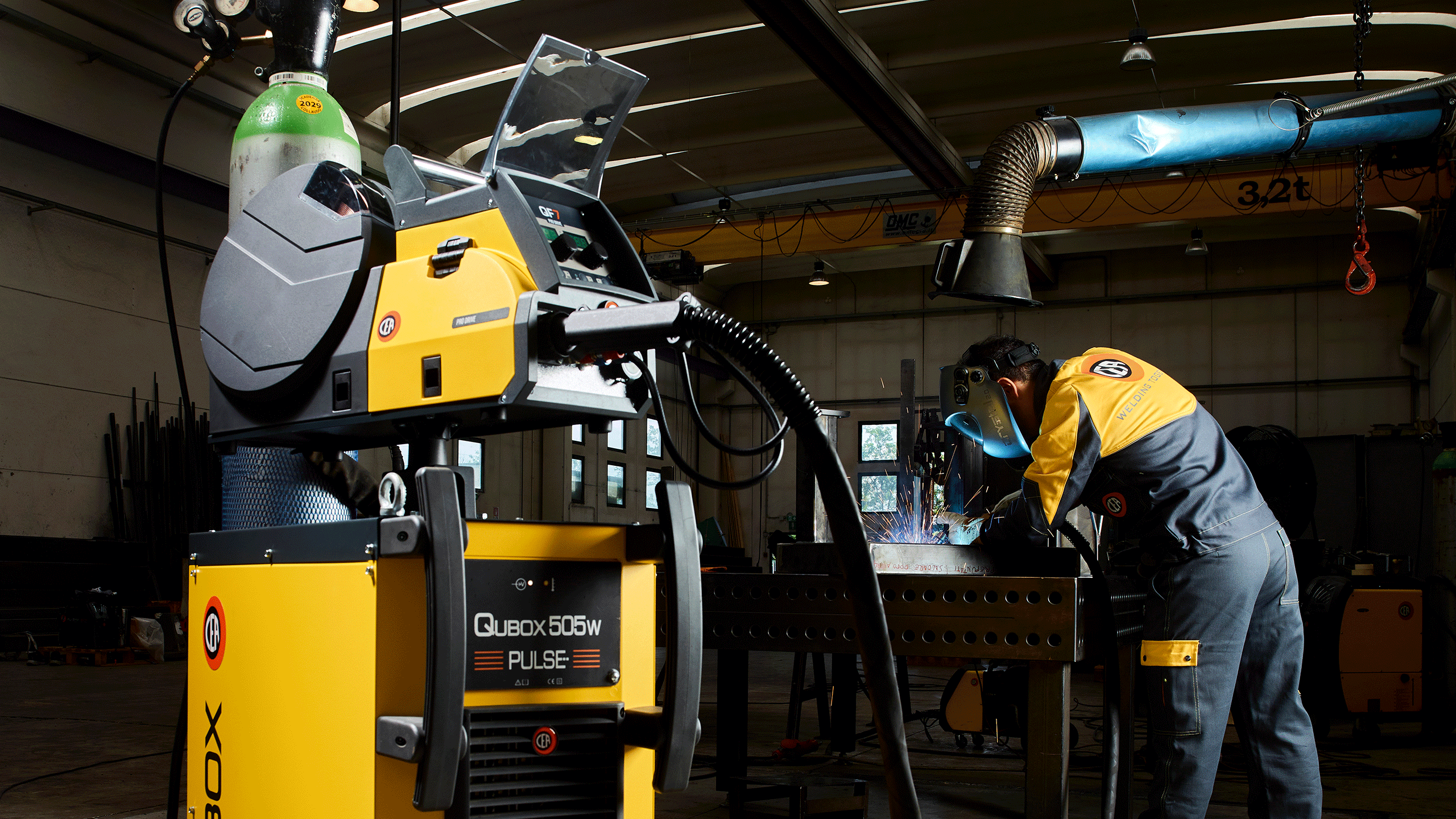

CEA renovate the product line by entering a group of important new welding solution as:

- QUBOX

- New HT 5 feeder with kit of Double Feeder

- New HS 5, SWF and SHS feeders

- New ULTRAFAST software for TIG’s

- MATRIX 3000 DC & AC/DC TIG’s with new wave forms

- TREO 1800 SYNERGIC

- DIGISTAR 2000 PULSE

2018

CEA officially launch in the market the first group of synergic mig/pulse special process:

- vision.PULSE-UP for a quicker and more precise vertical up welding

- vision.PULSE-RUN for a colder and faster pulsed welding

- vision.PULSE-POWER for a more penetrated and smoothly shaped welding on medium large thickness

2023

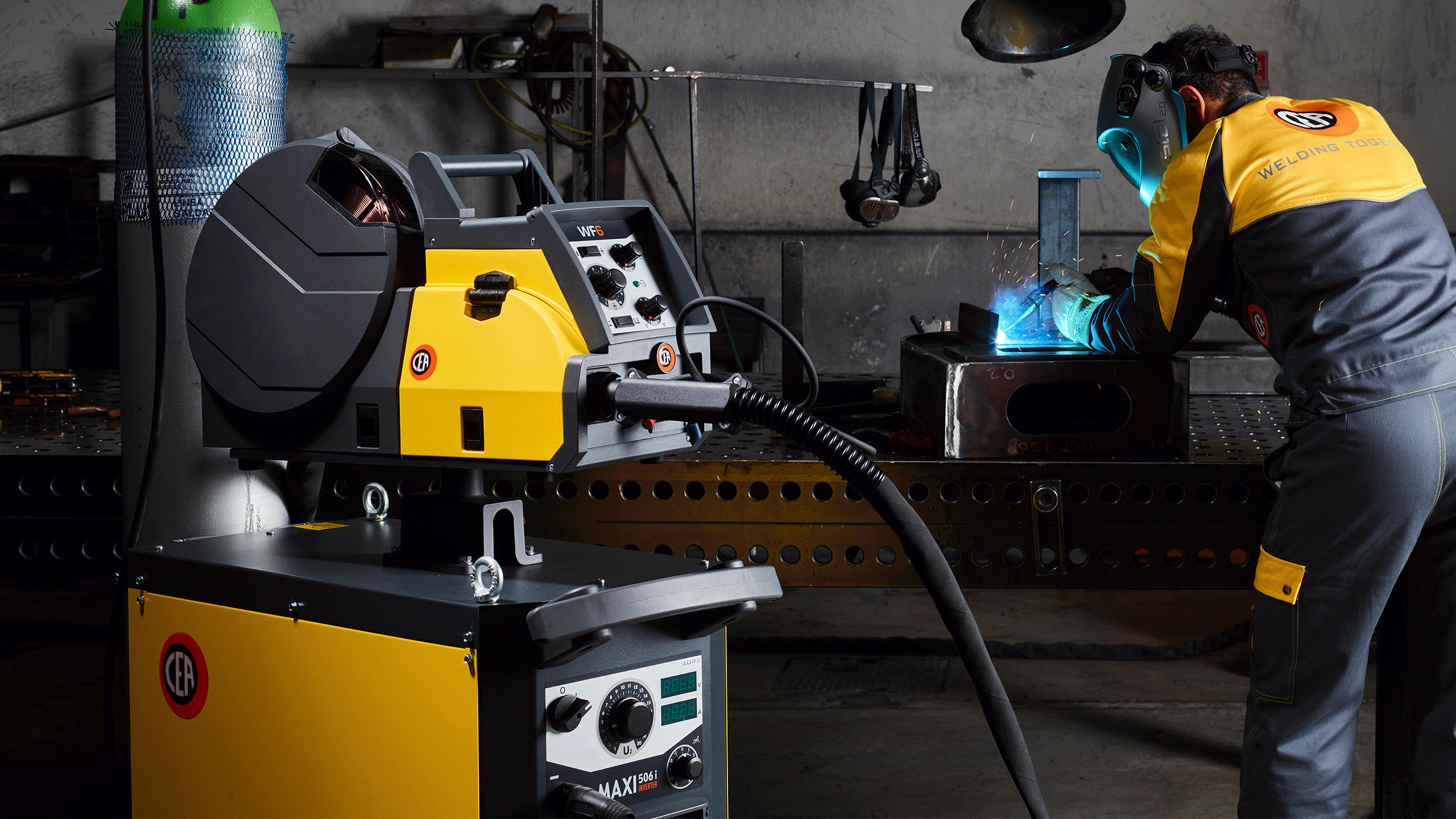

In SCHWEISSEN&SCHNEIDEN exhibition CEA breaking again into the welding world by presenting a complete new line of products. Driven by the usual industrial mentality and quality addiction, CEA launch DOGMA, SMARTCAR, DIGITECH VP3, MAXI I and many other interesting minor update.

A common spirit

Bridge 4 Companies

Welding machines. Robotics. Sawing machines. Metal sheet working. Apparently different sectors and distinct commercial networks, but they share many similarities. The companies that make up Bridge4Companies are above all united by the same passion and the same attention to the customer.

B4C is an aggregate of companies linked by the same spirit whose common denominator is the Annettoni family, historical owner and founder of CEA. Through great synergy, B4C has been able to create and grow over the years an aggregate of companies that now boasts important numbers.

The 4 companies are: CEA, worldwide brand focused on industrial welding and plasma cutting, TECNOROBOT, specialized in customised welding robotic systems, IMET, bandsaws, circular saws and innovative systems for metal cutting, and LAMETEC, metal sheet working.

Bridge4Companies counts more than 250 employees and sales in over 100 countries.

B4C is proof of the 4 companies’ great attachment to the territory overlooking the edge of Lake Lecco and along Adda River’s course, which, through great passion for their work and continuous research of quality, have managed to assert themselves on all major world markets.

www.bridge4companies.com