Arc welding

To face global market challenges, nowadays one of CEA’s plus-point is to have a very wide range of “hi-tech” inverter based products and a few conventional as well, fully in-house developed & manufactured too, in order to meet all needs of the industry. CEA’s large variety of arc welding products are really dedicated to all industrial and professional applications for MMA, TIG, MIG-MAG and MIG PULSED welding , some of which customized to complex automation and robotized procedures.

SMART / SMARTCAR PULSE

CONVEX MOBILE / CONVEX MOBILE PULSE

CONVEX / CONVEX PULSE

DOGMA / DOGMA PULSE

DIGITECH VP2 COMPACT

MAXI i

Q-YARD

MAXIQ

QUBOX / QUBOX PULSE

DIGITECH VP3

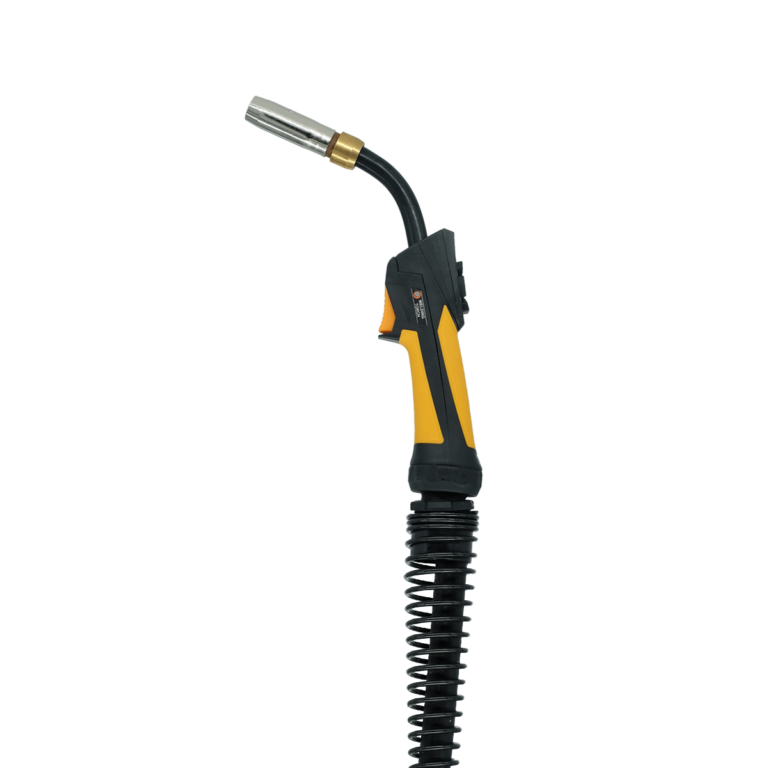

CEA C TORCH

CEA CX/CXH TORCH

CEA DIGITORCH DX/DXH

CEA CX/CXH UP/DOWN TORCH

vision.ARC2

vision.COLD

vision.ULTRASPEED

vision.POWER

vision.PIPE

vision.PULSE-UP

vision.PULSE-RUN

vision.PULSE-POWER

SMARTMIG

COMPACT

WF5

MAXI

SWF

WF6

WF7

MF4

MF4 YARD

QF7 W PRO DRIVE

HT6 PRO DRIVE

YARD 4 W

MINI YARD 4 W

RAINBOW HF

MATRIX HF

Matrix X HF

MATRIX HF-R

MATRIX X HF-R

MATRIX AC/DC

MATRIX X AC/DC

MATRIX AC/DC-R

MATRIX X AC/DC-R

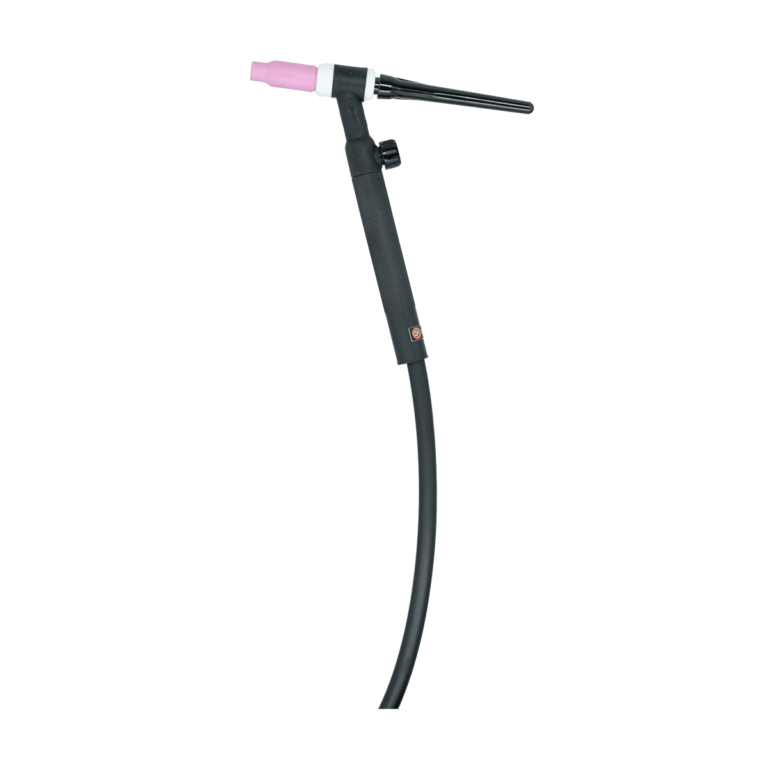

CEA TX/TXH TORCH

CEA RTX TORCH with built in gas valve

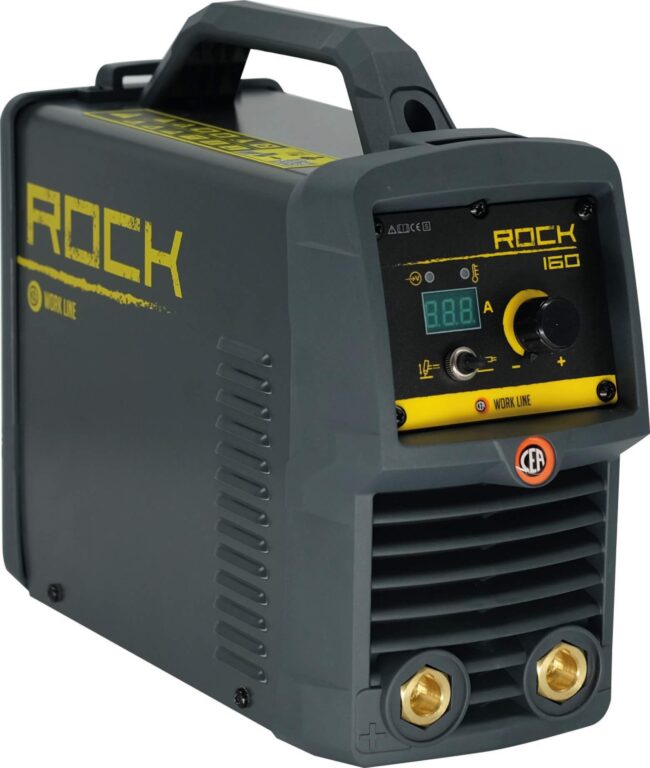

ROCK

MATRIX E

ARC

TRIARC

ARCTRONIC

CEA CALIBRATION SERVICES

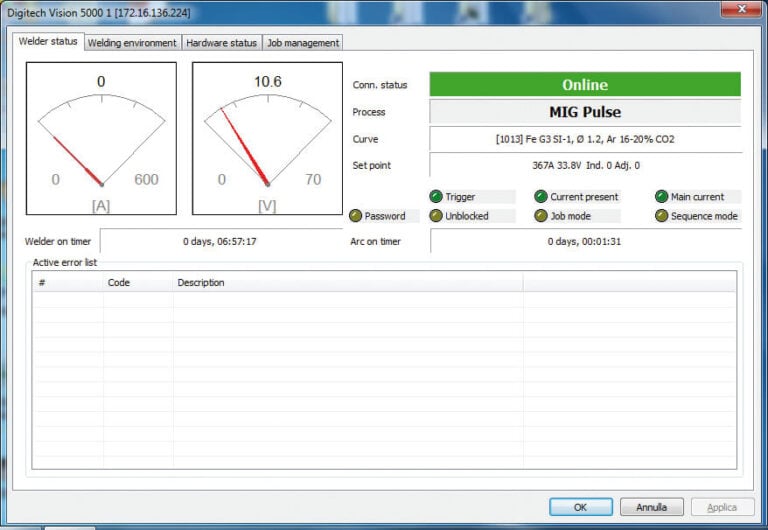

CEA WELDER MANAGER

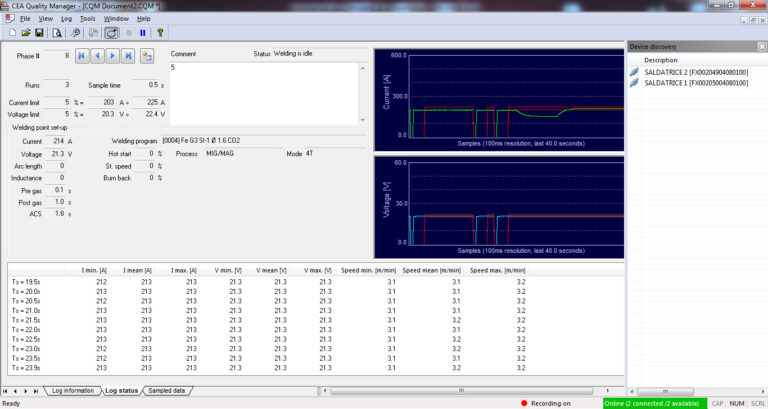

CEA QUALITY MANAGER

EN 1090

FREQUENTLY ASKED QUESTIONS

If you are looking for technical information about our welding products, we encourage you to consult the FAQ section below. We have compiled a list of commonly asked questions and detailed answers to provide you with the information you need. Whether you have questions about product usage you can find the answers here.

We understand the importance of having fast access to accurate technical information, and we are committed to providing you with comprehensive resources to support your welding needs. If you cannot find the information you are looking for in the FAQ section, please feel free to reach out to our customer team for further assistance.

How to set vision.COLD

Vision.COLD is one of many CEA special programs dedicated to MIG welding. The ideal use of this special program is on thin thicknesses, to avoid the deformations that would occur with a simple MIG. To discover this process quickly and completely, watch the dedicated video on our YouTube channel here. If you want to find out more, do not hesitate to visit our dedicated section of the site here.

How to set vision.ULTRASPEED and why to set-up DYNAMICS

Vision.ULTRASPEED is one of the many special CEA programs dedicated to MIG welding. Ideal for speeding up any production, this process makes MIG welding up to 50% faster. To discover this process quickly and completely, watch the dedicated video on our YouTube channel here. If you want to find out more, do not hesitate to visit our dedicated section of the site here.

How to set vision.PIPE for a perfect first pass

Vision.PIPE is one of CEA’s many special programs dedicated to MIG welding. Designed to have an incredible arc stability in any torch position, this process allows you to perform MIG welding on pipes in a simplified and professional way. To discover this process quickly and completely, watch the dedicated video on our YouTube channel here. If you want to find out more, do not hesitate to visit our dedicated section of the site here.

How to set vision.POWER

Vision.POWER is one of the many special CEA programs dedicated to MIG welding. This process is the best solution for any MIG welding requiring high and quality penetration. To discover this process quickly and completely, watch the dedicated video on our YouTube channel here. If you want to find out more, do not hesitate to visit our dedicated section of the site here.

How to set COLD.TACK

COLD TACK is one of the many exclusive CEA programs dedicated to TIG welding. This program is ideal for obtaining perfect and identical welding spots every time, simplifying spot welding in any position and situation. To discover this process quickly and completely, watch the dedicated video on our YouTube channel here.

How to set R.C.T. (RUNNING COLD TACK)

RUNNING COLD TACK is one of the many exclusive CEA programs dedicated to TIG welding. This program is ideal for obtaining perfect tig-spot-welding in any position and situation. This incredible process will help you achieve incredible results even on very fine thicknesses. To discover this process quickly and completely, watch the dedicated video on our YouTube channel here.

What is DUTY CYCLE and how does it work?

The DUTY CYCLE is a specification that defines the number of minutes, within a period of 10 minutes, during which a given welder can safely produce a certain welding current. Would you like to know more? Don’t worry, you can find a dedicated article at the following link What is DUTY CYCLE?. Here there are all the details about this indispensable parameter for a correct evaluation of the power source quality.

Safety norms

CEA meets the highest quality standards in all its products, also in safety requirements. We always want to give you the best performance with the maximum safety and, for doing this, we’ve created clear and detailed Safety Norms. Read the following link for discovering all the Safety Norms you’ve to fulfil for using your CEA at the best: Safety Norms.