How long do plasma consumables last?

HOW LONG DO PLASMA CONSUMABLES LAST? A good operator with well-maintained plasma arc cutting equipment can save hours of downtime and thousands of Euros in operating expenses. These savings will result in greater profits for your cutting operations and your company.

Please carefully ready what's written in in this guide, it tells you about how to get a longer life of the consumable parts. But, don’t forget that they are “consumables”, so they have to be replaced sooner or later.

CS ORIGINAL SPARES PARTS

CS is our guarantee hallmark for CEA PLASMATECH consumables. All original consumables belonging to SK and SKM torches of SHARK equipment are CS marked to prove the origin.

The CS mark, present on all consumables, is the guarantee that all declared performances can be achieved.

Geometric shape study of torch components, quality in their employed materials, precision in machining and coupling - the results of years of experience - form the basis of SK and SKM torch development and utilization with our cutting power sources.

The use of CS marked original consumables is strictly recommended. Using non original CS marked components will render void all warranty and CEA PLASMATECH can no longer be deemed responsible for any consequent accident or injury which might occur.

Highlight:

Plasma consumable life depends on a plenty factors, let's have a look to a few ones.

• Average duration (in seconds) of each cut cycle and number of starts

• Amperage

• Using consumables until they "blow"

• Moist air

• Cutting speed

• Material thickness

• Consumable selection

• Wrong piercing method

Usually, in normal conditions, we can say that the electrode will wear out first during machine cutting. Typical life time of a set of consumable should last about 1 to 3 hours for about 120 A of mechanized cutting, it's in function of the job. Cutting at lower current may gets longer consumable life.

Here below we will see some of the points below, but read 'till the end of the article for discovering how you can find all the other information!

DON'T USE CONSUMABLES UNTIL THEY "BLOW"

Using severely worn consumables can not only ruin a good piece of metal, it can cause expensive torch failures. An experienced operator can tell consumables are worn by the sound coming from the torch or even the color of the arc. However, the best way to judge the condition of your consumables is to periodically inspect your consumable as soon as when you notice that the cut quality is deteriorating. It's advisable to keep a record of the average parts life over time and develop guidelines for expected parts life based on the amperage, material, and thickness you are cutting.

Once average life is established the operator will know when to check and or

replace consumables preventing a catastrophic failure.

Highlight:

Moist air causes extremely short consumable life and poor cut quality and, together with low air-flow rate, is the most common cause of excessive consumable wear. Making sure the air, feeding into the machine, is free of water and oil, you will maximize your consumables’ life. Use a proper filter can solve this problem.

CONSUMABLE SELECTION

Consumable selection depends on the material and thickness being cut, the amperage and plasma gas used and other arc cutting parameters.

The operator's manual that came with your plasma system will tell you which consumables to use.

Using incorrect consumables can lead to shortened parts life and reduced cut quality.

It is particularly important that you run parts at the correct amperage. If the amperage is too low, the cut will be shoddy. If it is too high, the nozzle life will suffer.

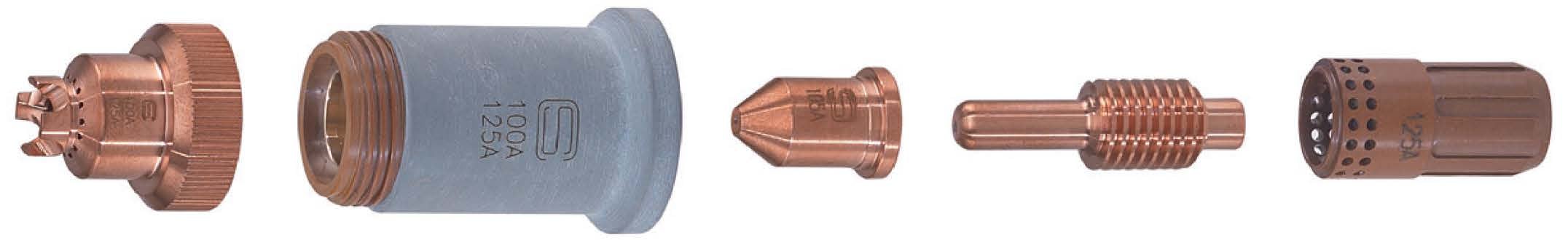

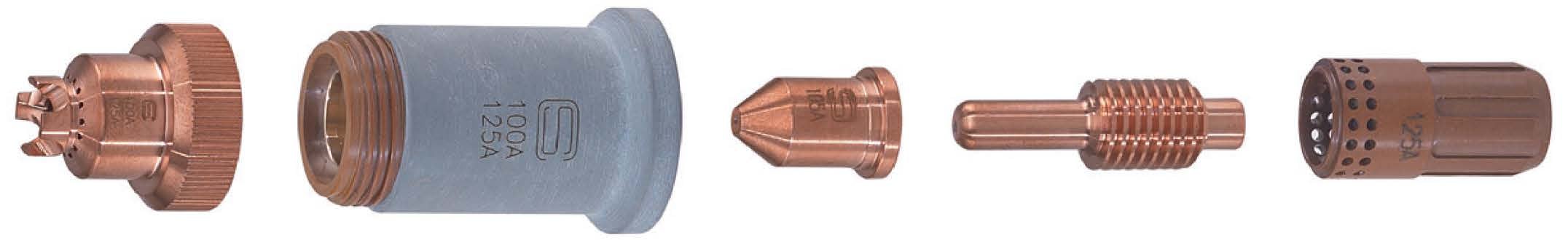

Starting from the left: Shield cap | External nozzle | Nozzle | Electrode | Swirling ring

Starting from the left: Shield cap | External nozzle | Nozzle | Electrode | Swirling ring

DO YOU WANT TO KNOW MORE?

Do you like this quick guide? If yes, register your CEA product in our website and take advantage of our up to 5 year warranty. By this registration you will enter also in a world of tip&tricks guide for have the best from your CEA!

READ ALSO: "What is duty cycle?"