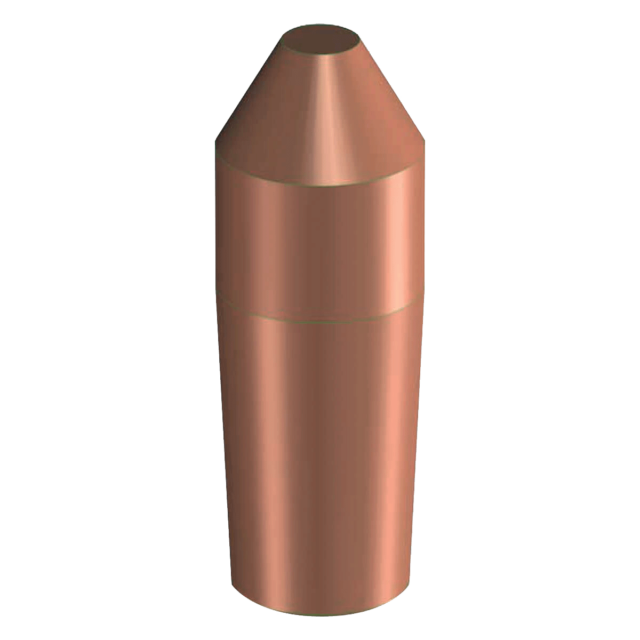

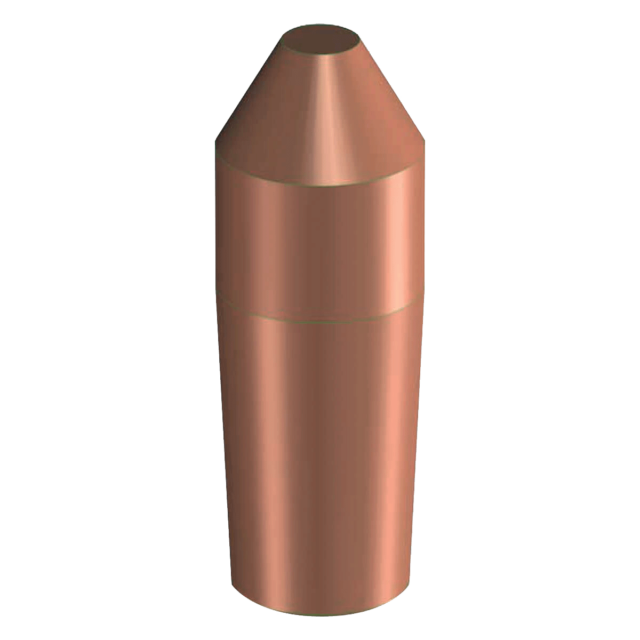

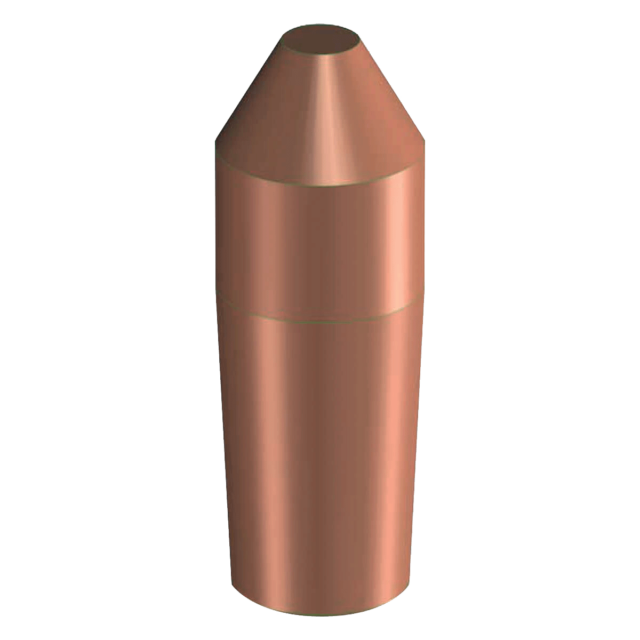

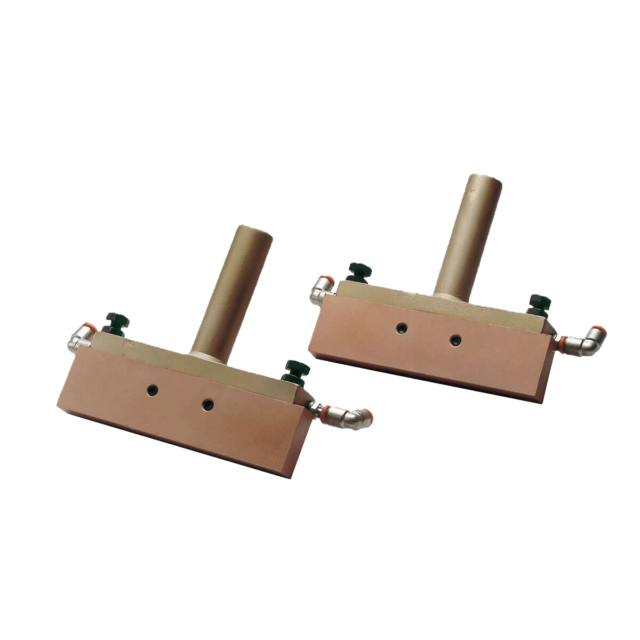

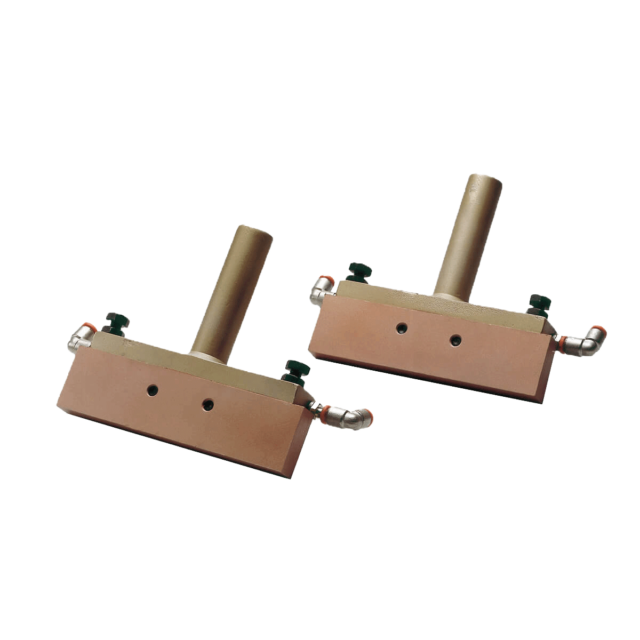

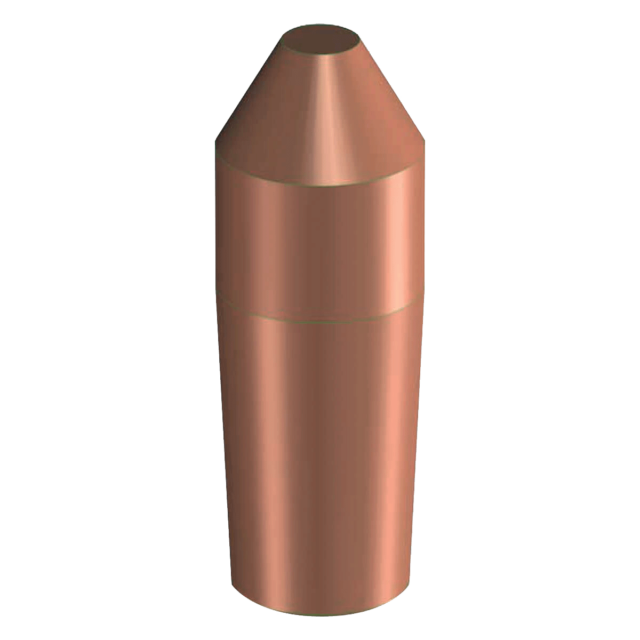

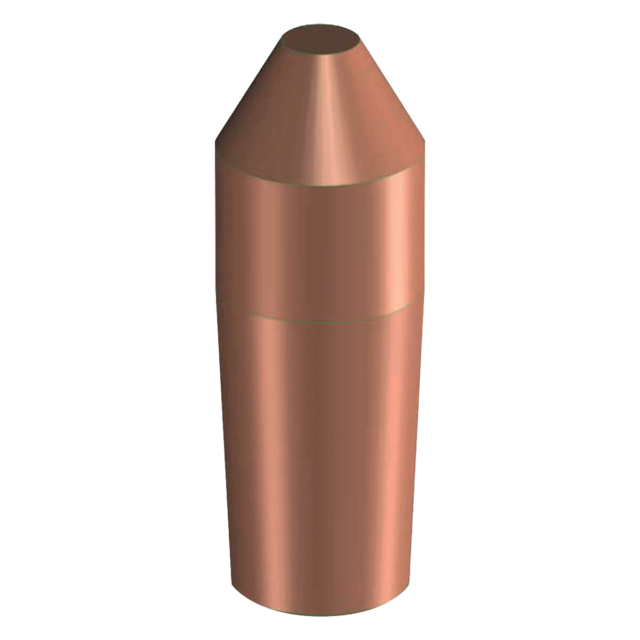

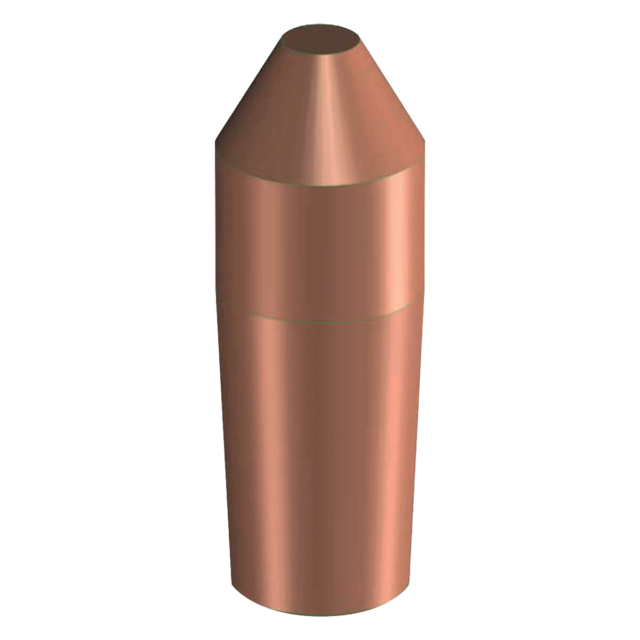

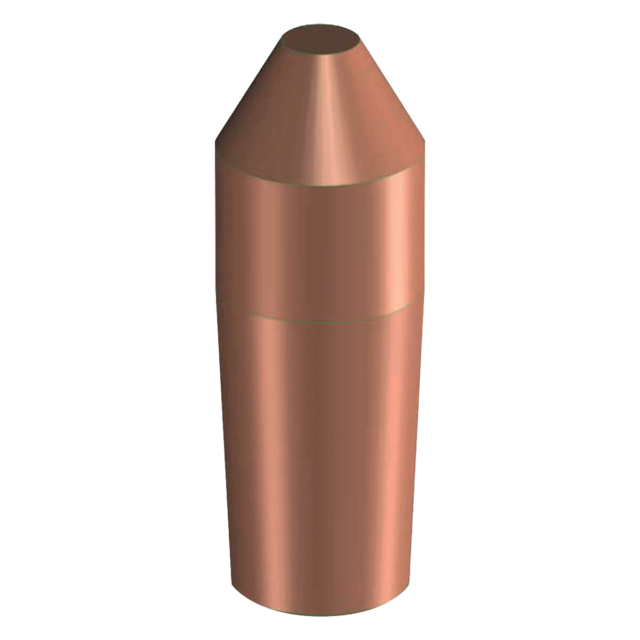

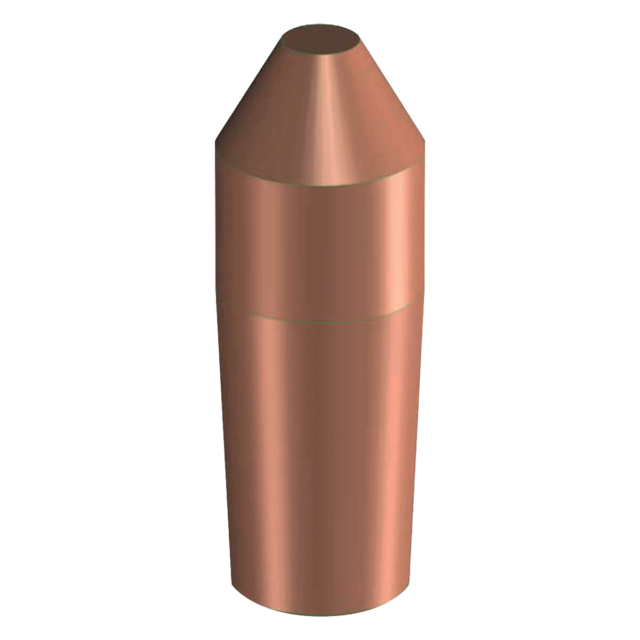

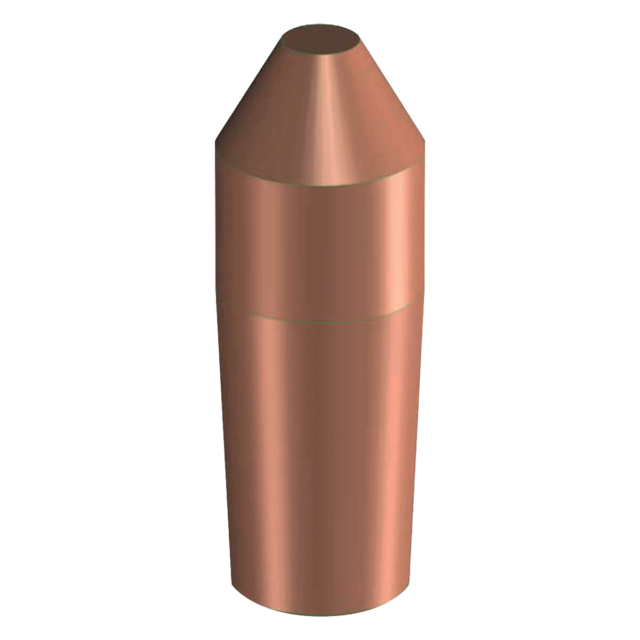

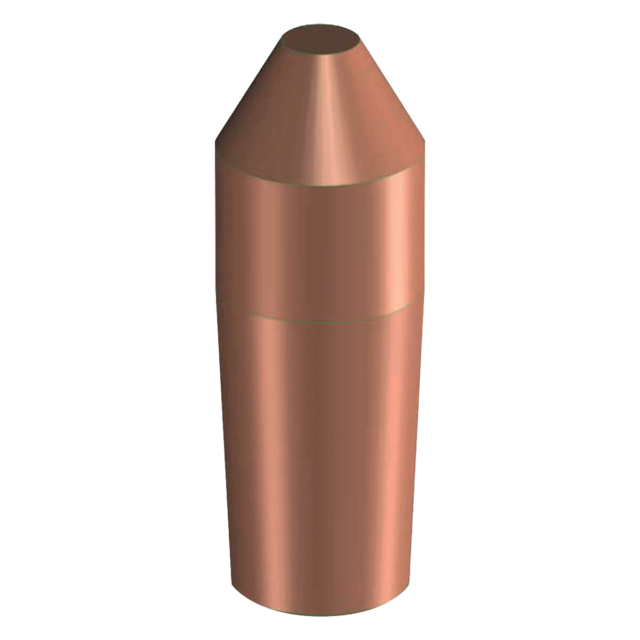

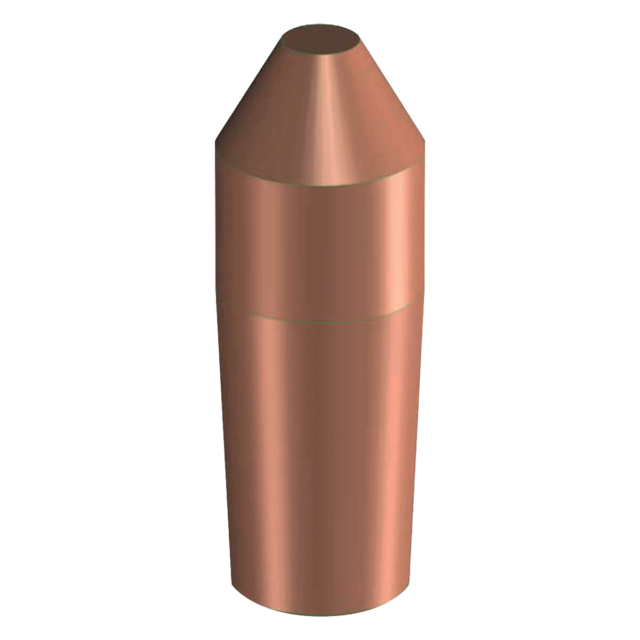

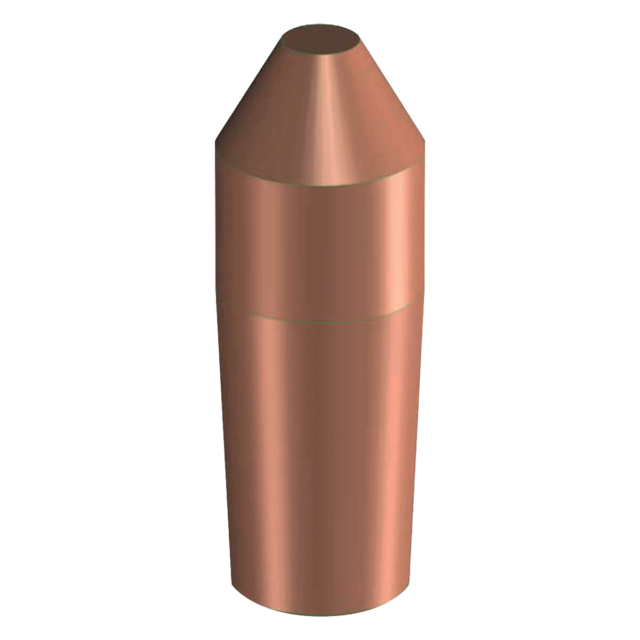

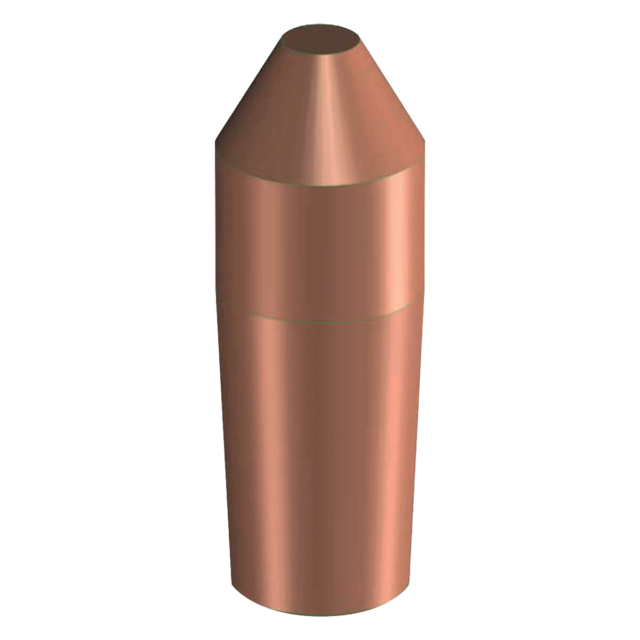

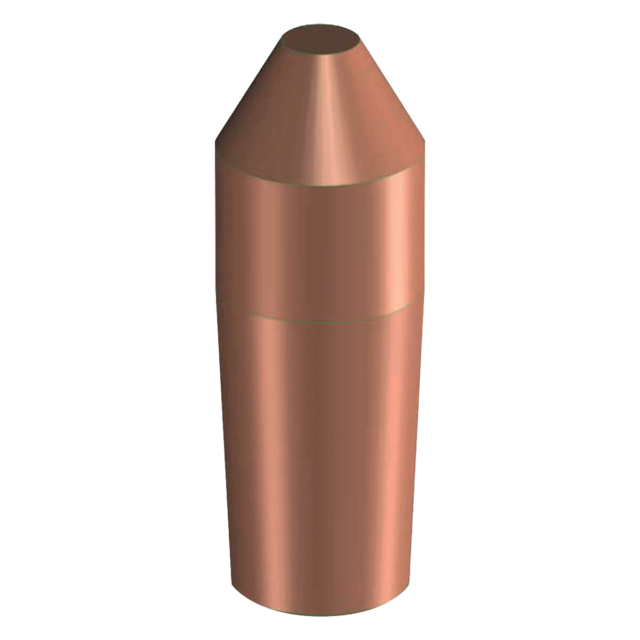

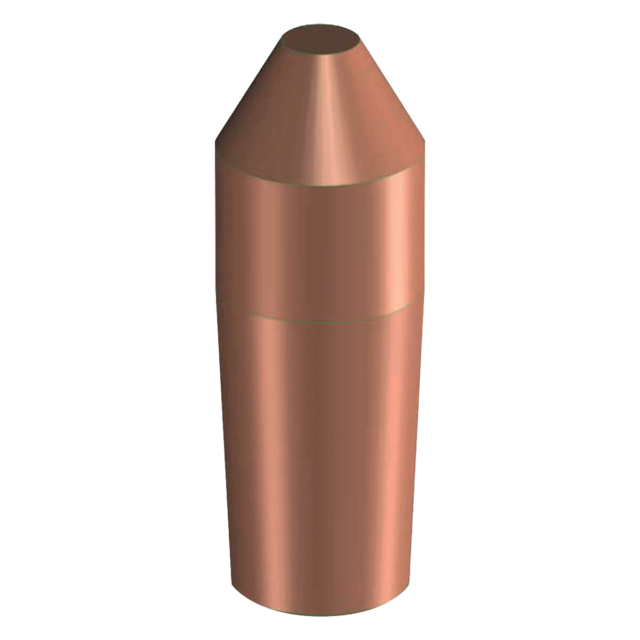

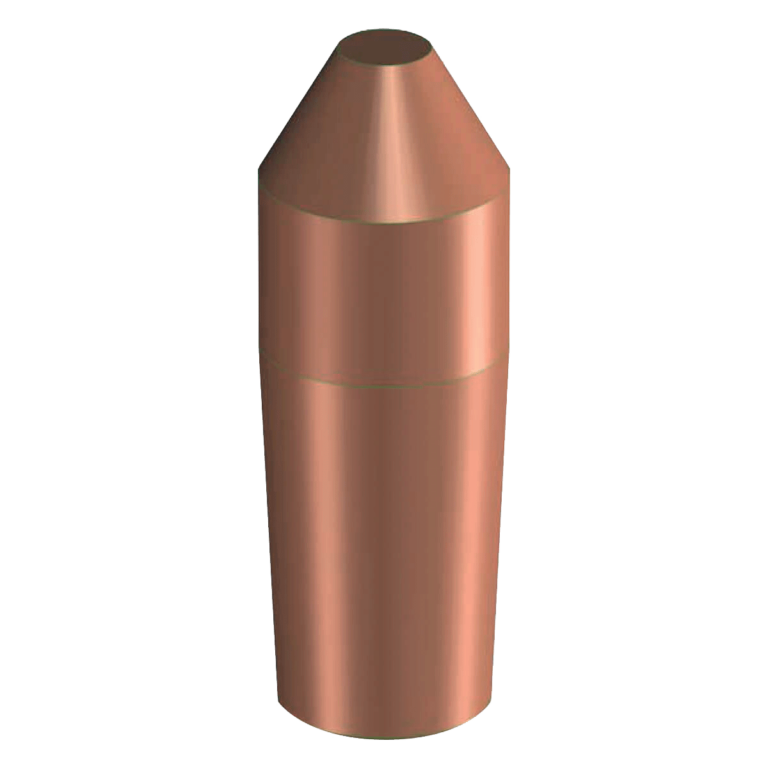

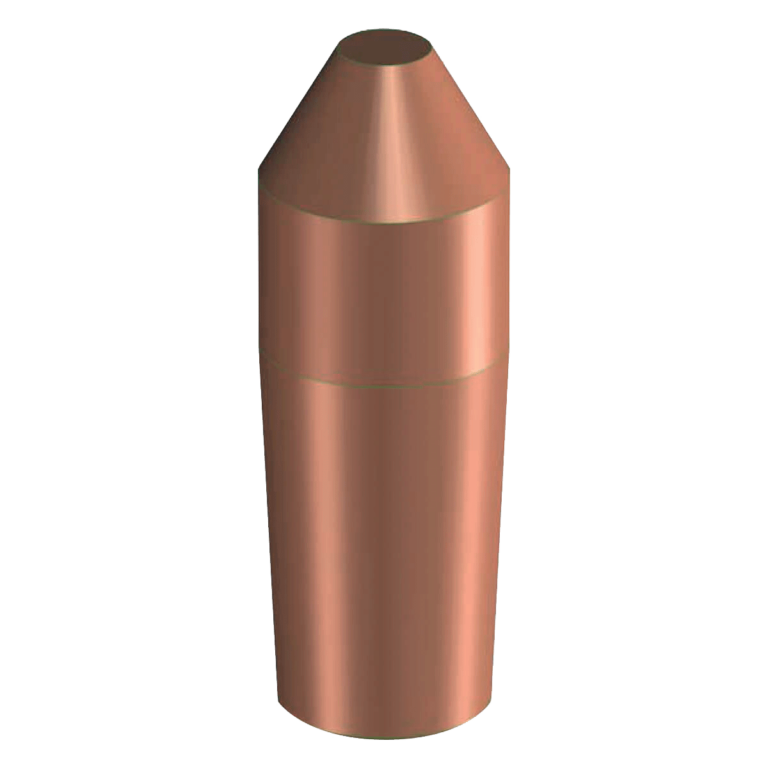

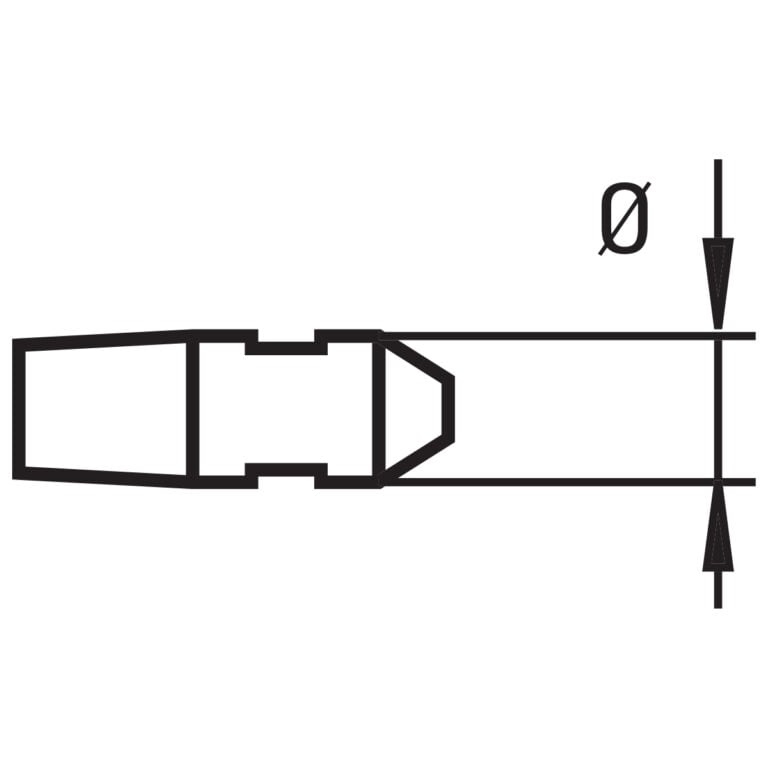

Set of pipe tips with electrodes depth 115 mm

"*" indicates required fields

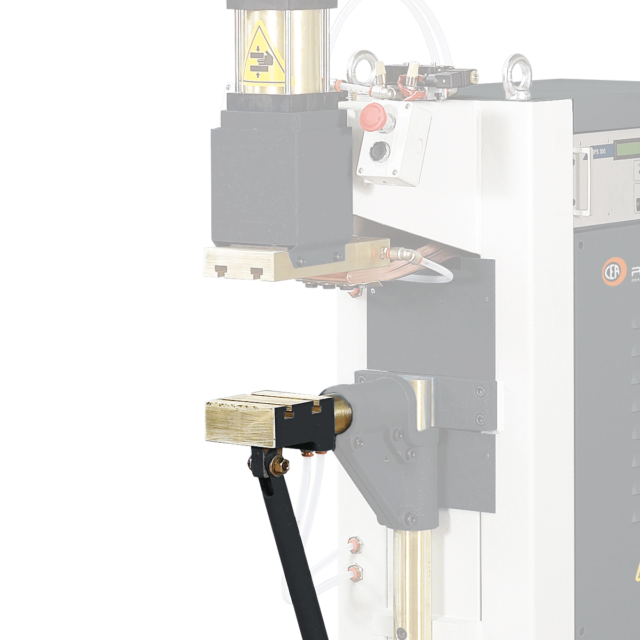

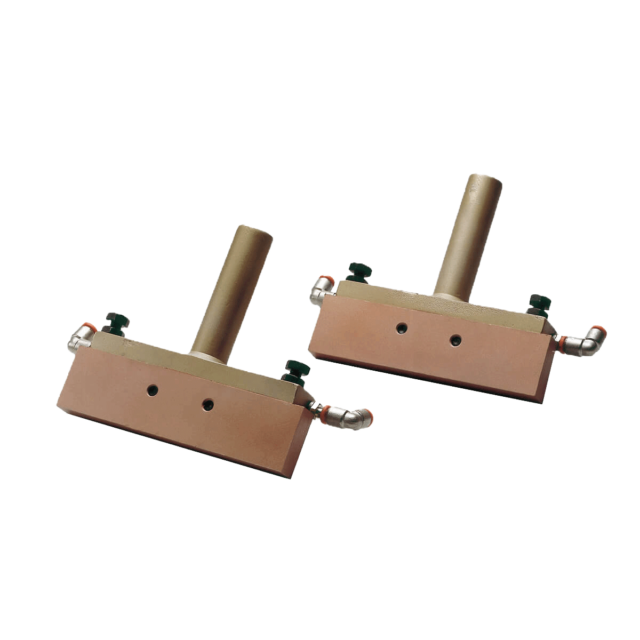

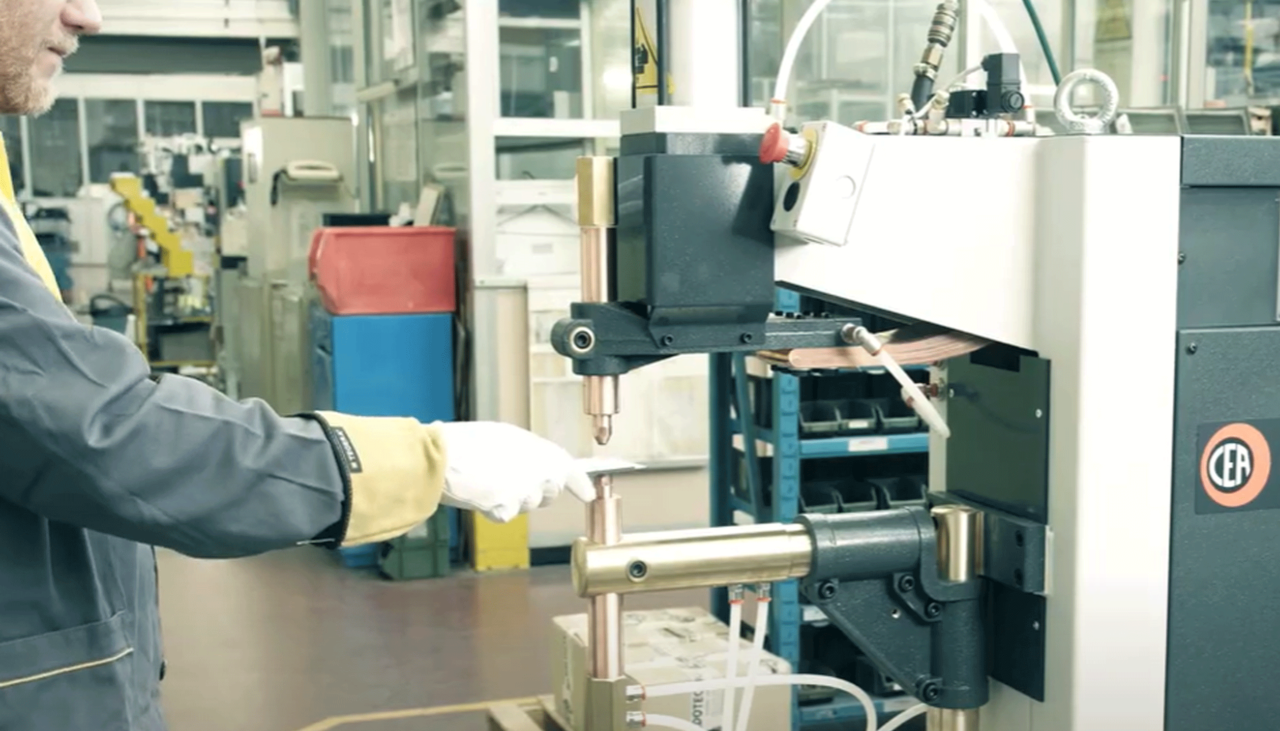

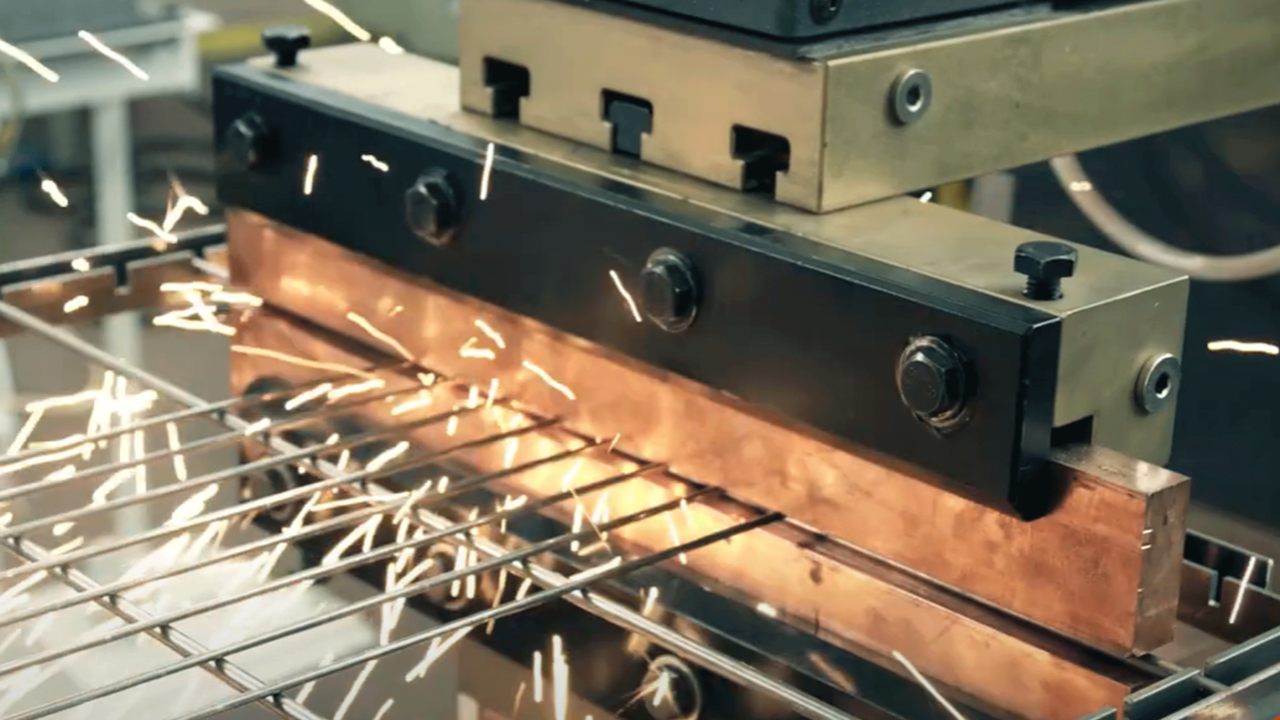

Being suitable for both spot and projection welding jobs, PPN models fully satisfy an extremely large variety of the heaviest mass production industrial applications.

Equipped with a microprocessor control and safety concomitant side buttons, upon request they can also be supplied fitted with special controls and in different configurations.

EQUIPPED WITH:

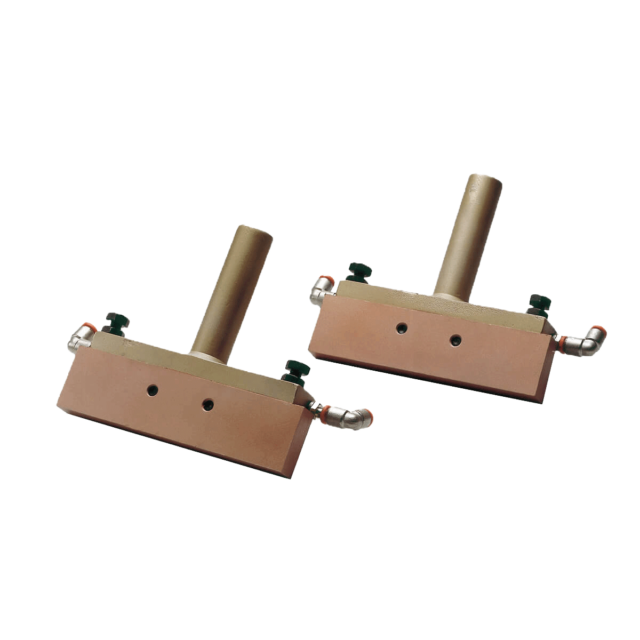

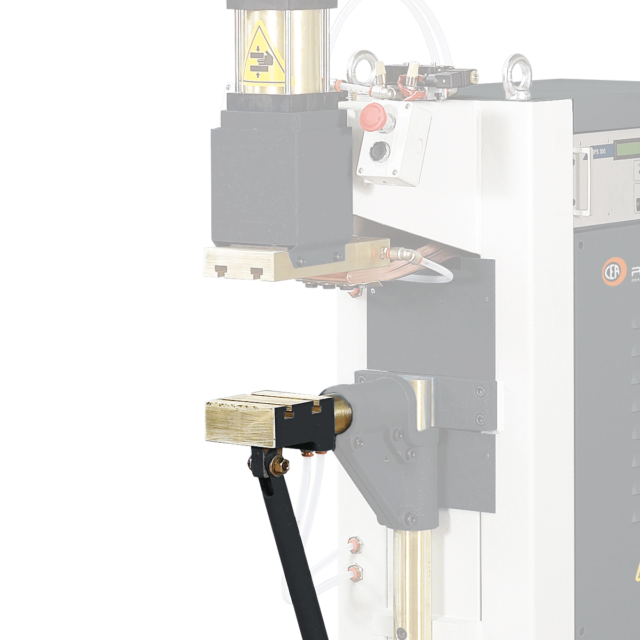

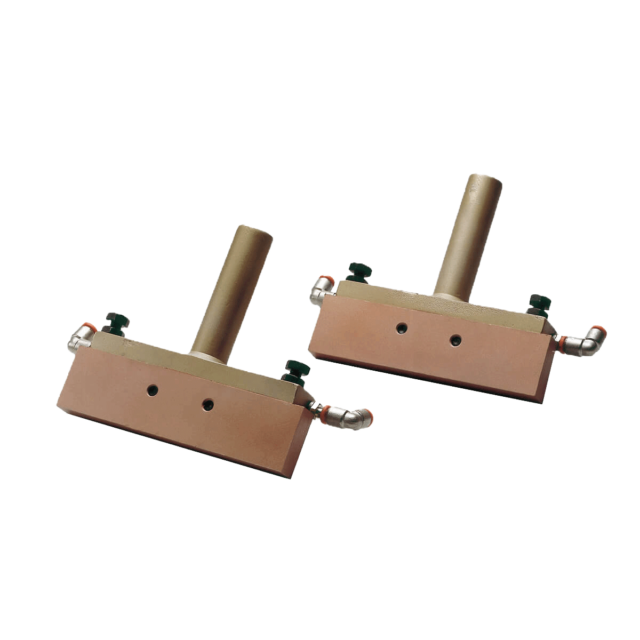

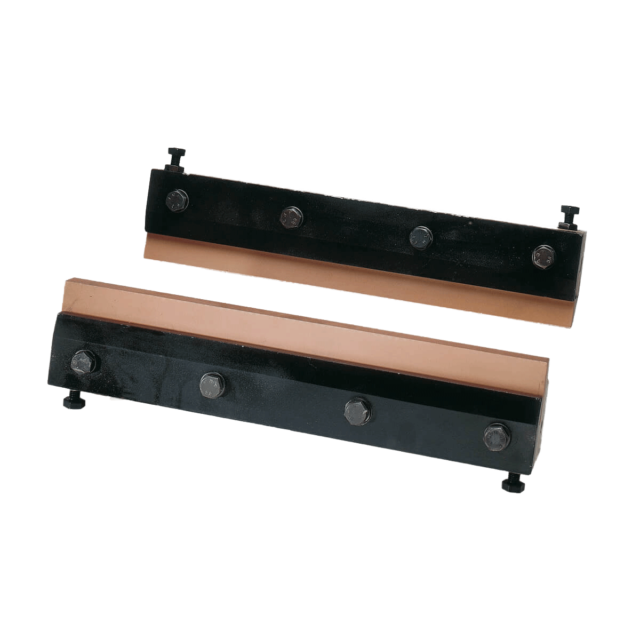

All supplied with lower platen adjustable in height and fitted with T-slots, enable the quick assembly of barholders, of electrodeholders or any dedicated tooling for a specific application.Platens gap is easily and quickly adjustable without any intervention on the secondary circuit (patent pending).

Set of pipe tips with electrodes depth 115 mm

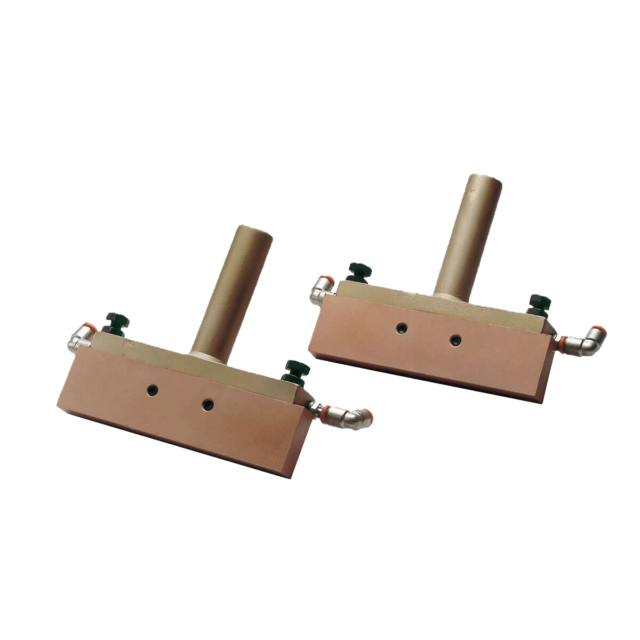

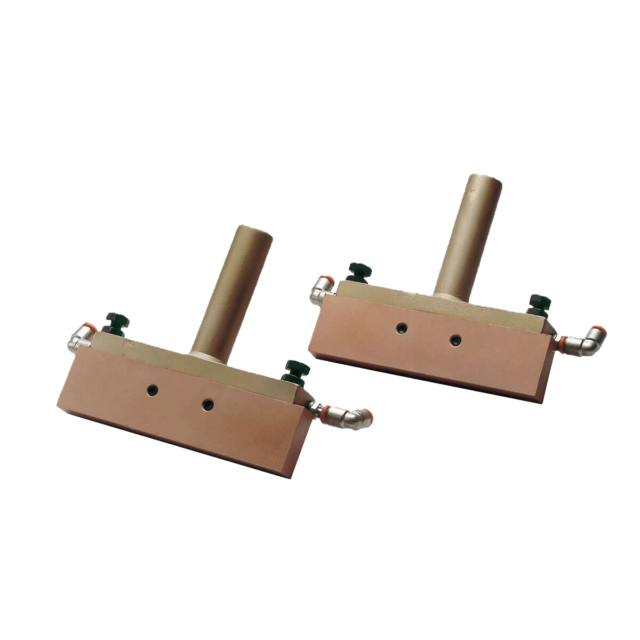

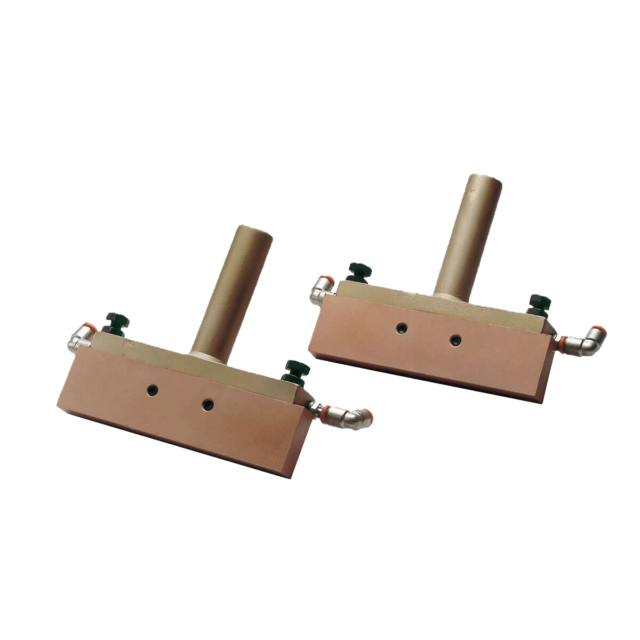

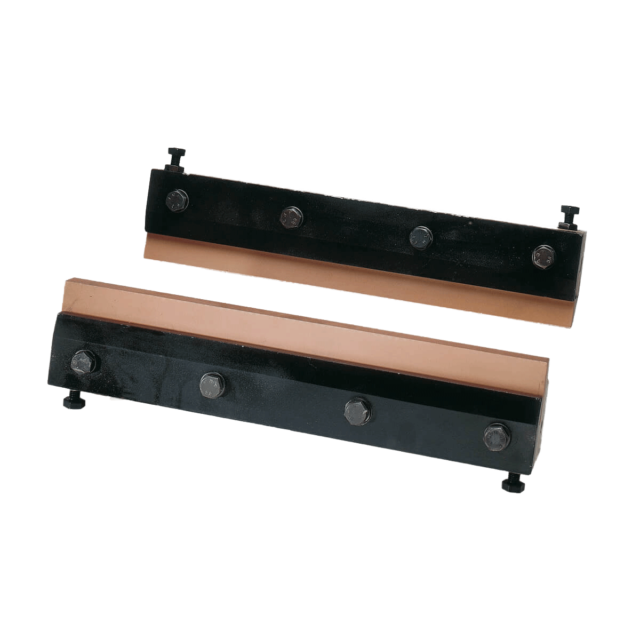

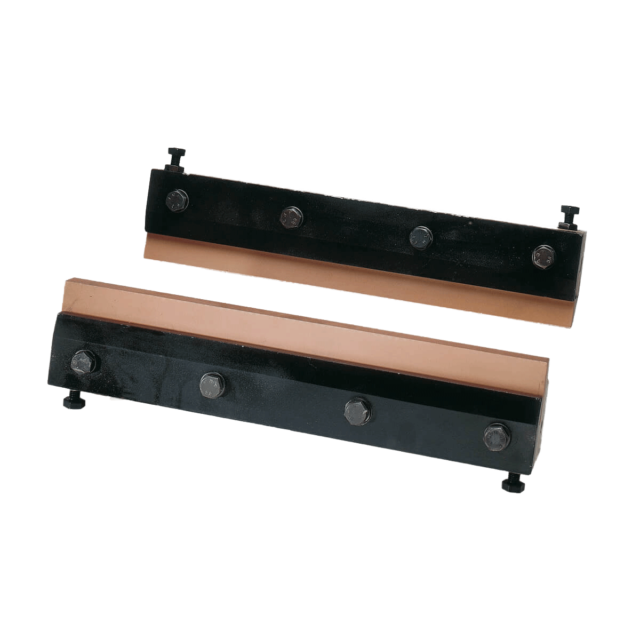

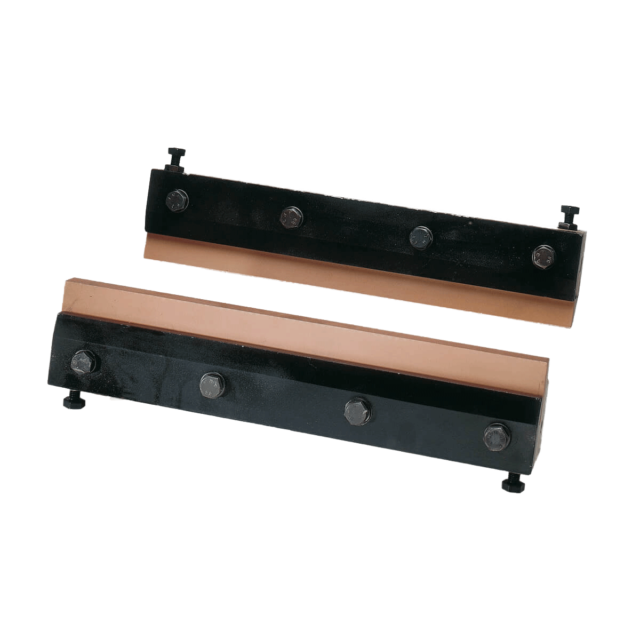

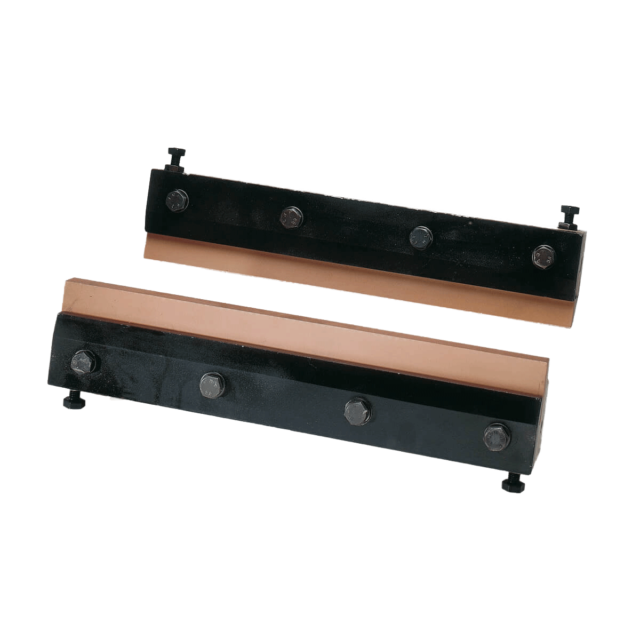

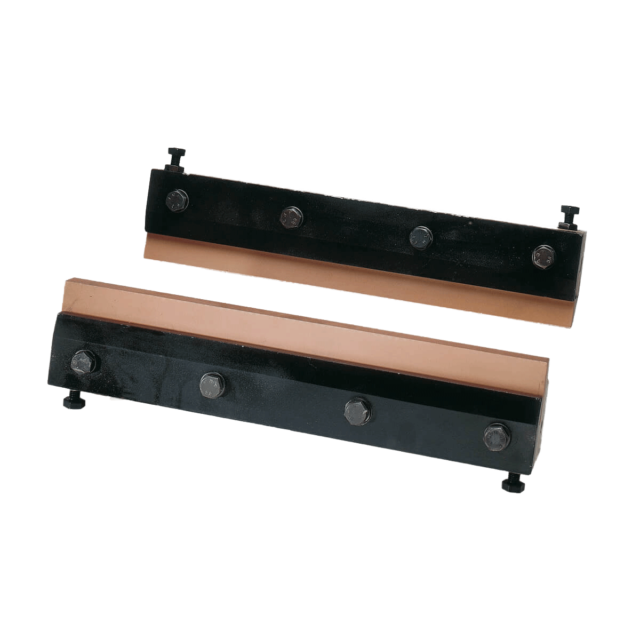

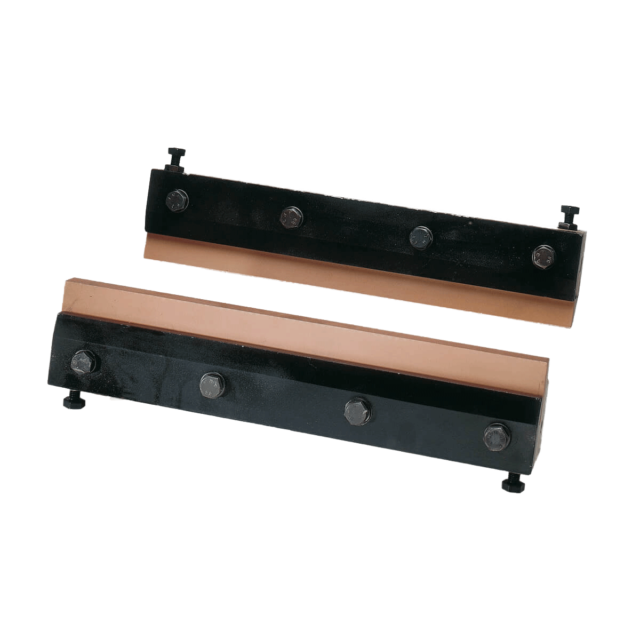

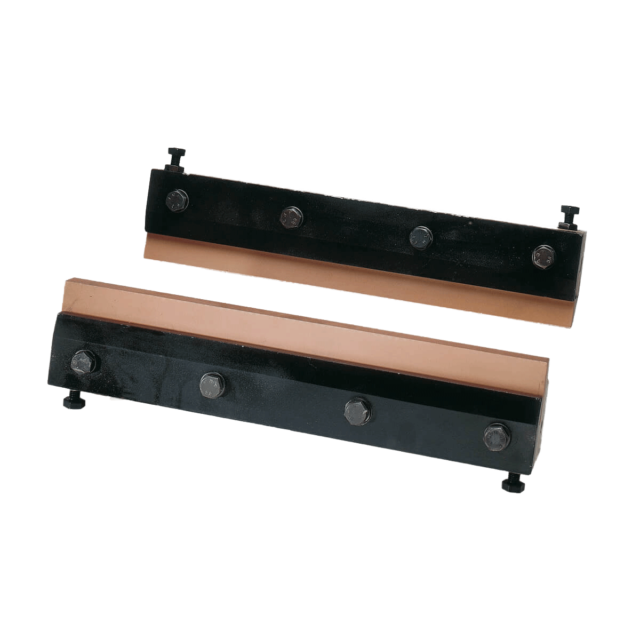

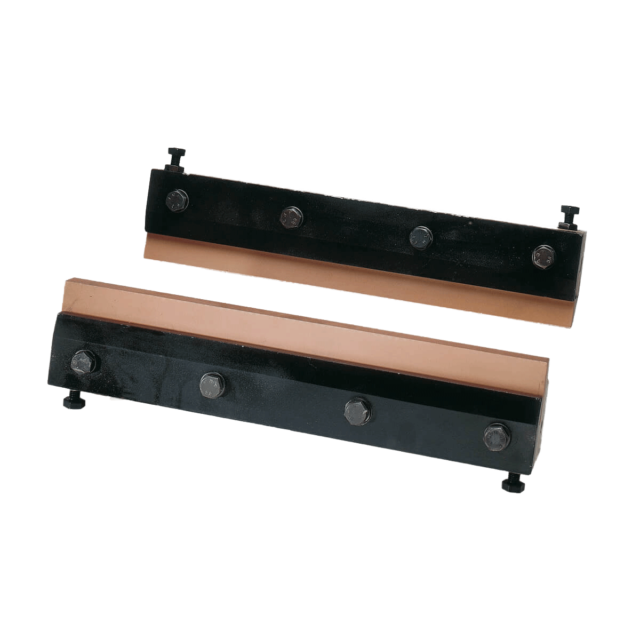

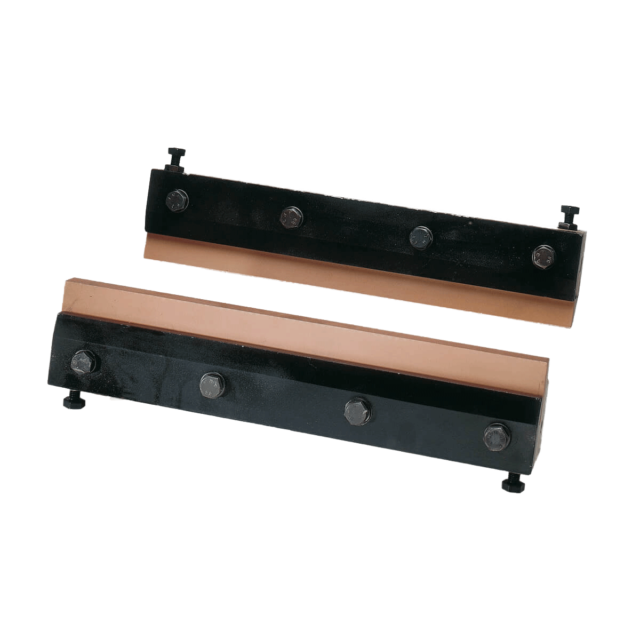

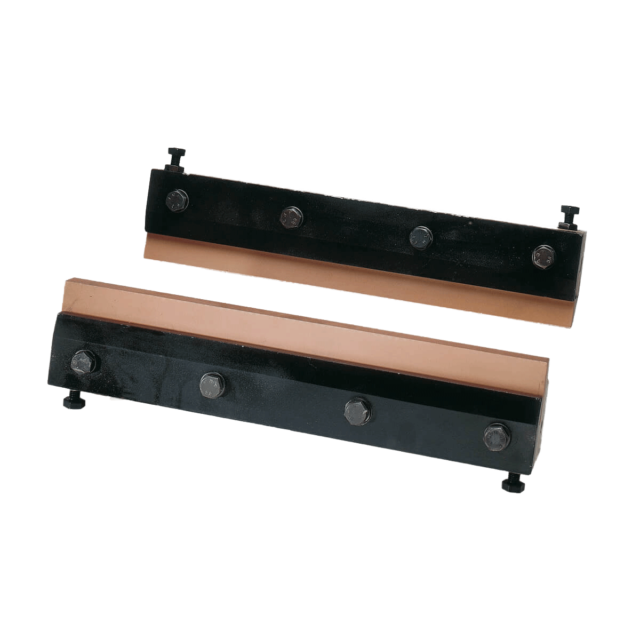

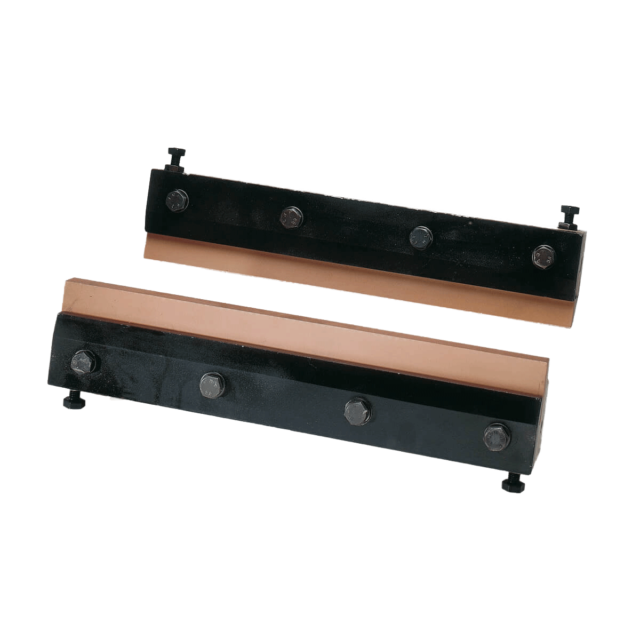

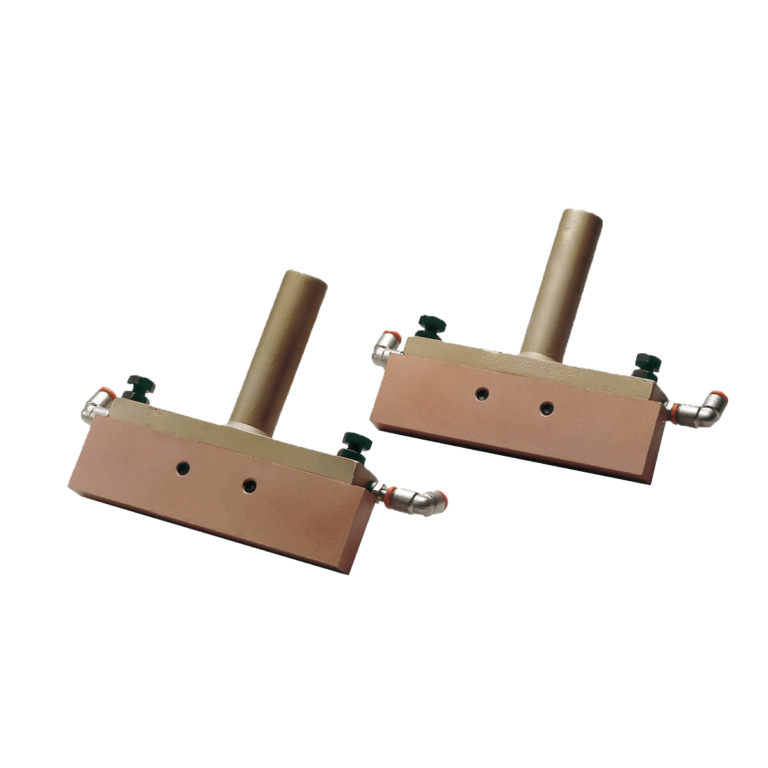

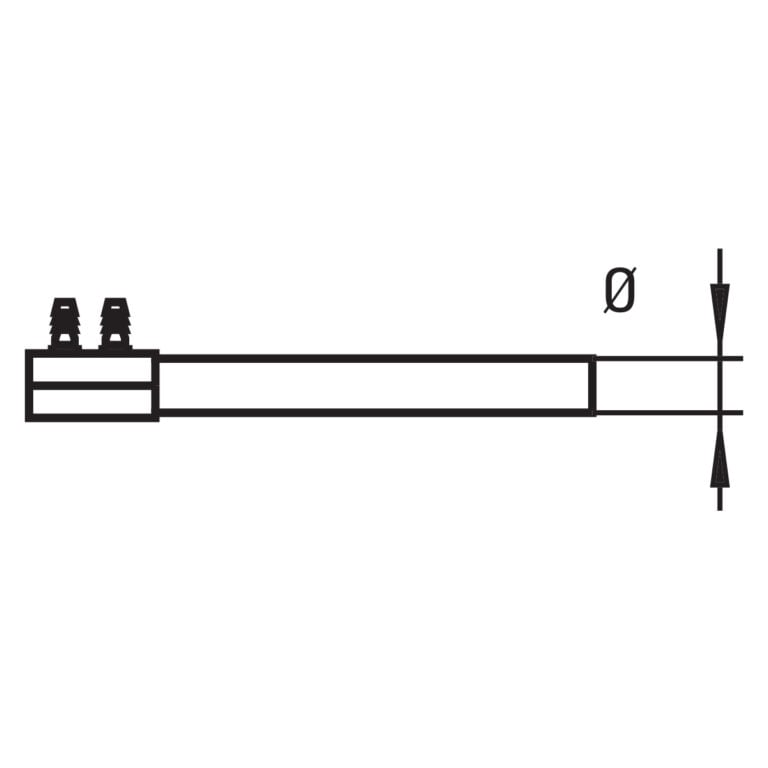

Set barholders with 200 mm bars

Set barholders with 400 mm bars

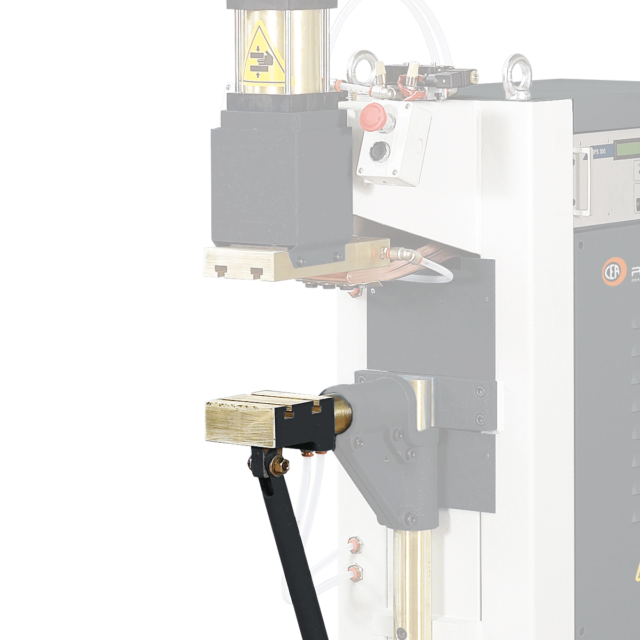

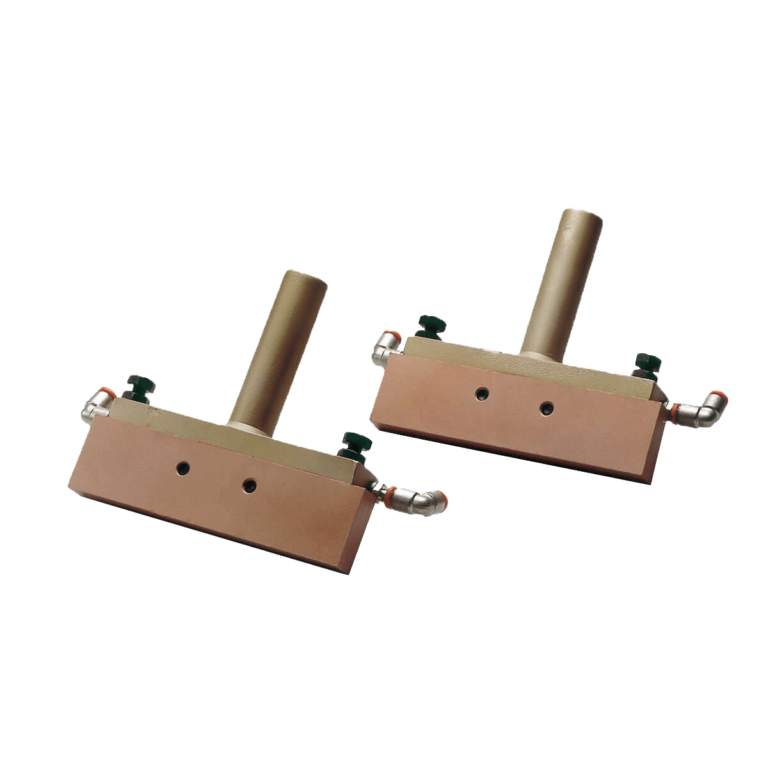

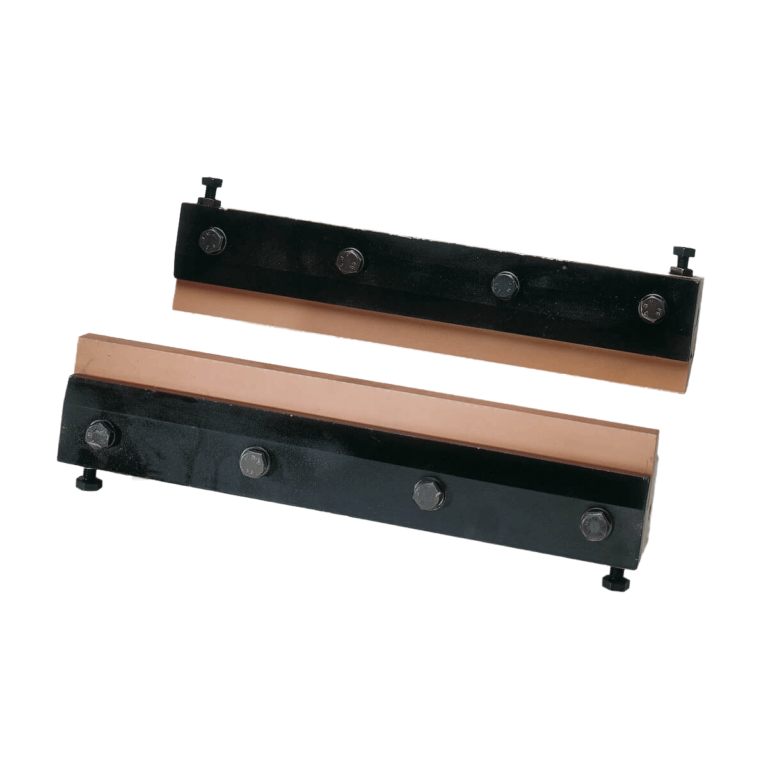

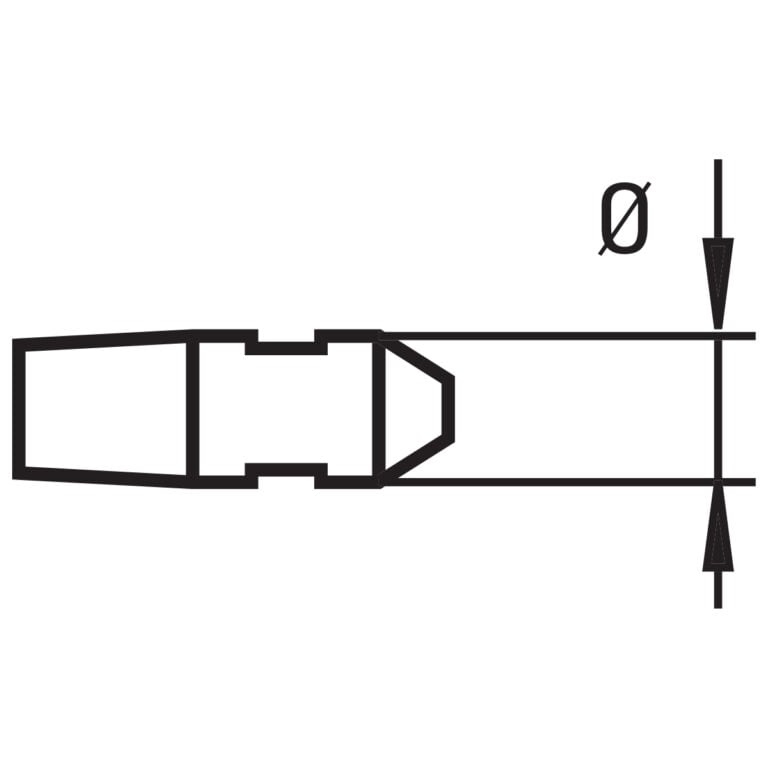

Set electrodeholders with electrodes

Set electrodeholders with electrodes

Set electrodeholders with electrodes

Set electrodeholder supports

Set of electrodeholder supports

Set barholders with 400 mm bars

Set barholders with 600 mm bars

Set barholders with 400 mm bars

Set barholders with 600 mm bars

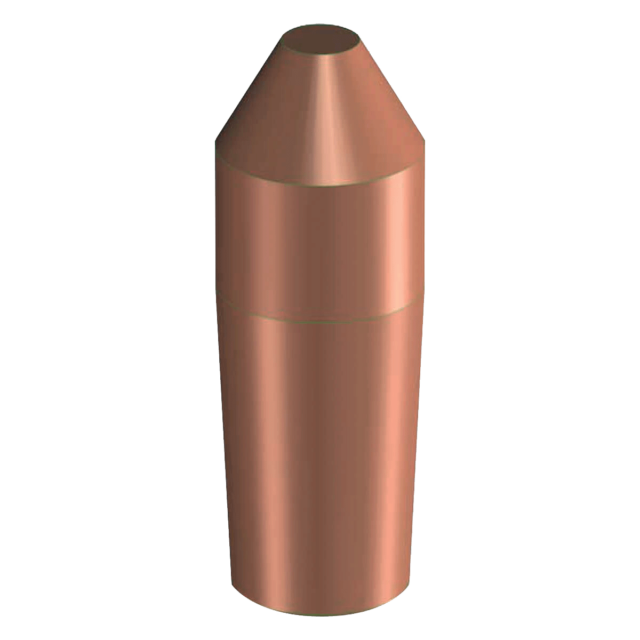

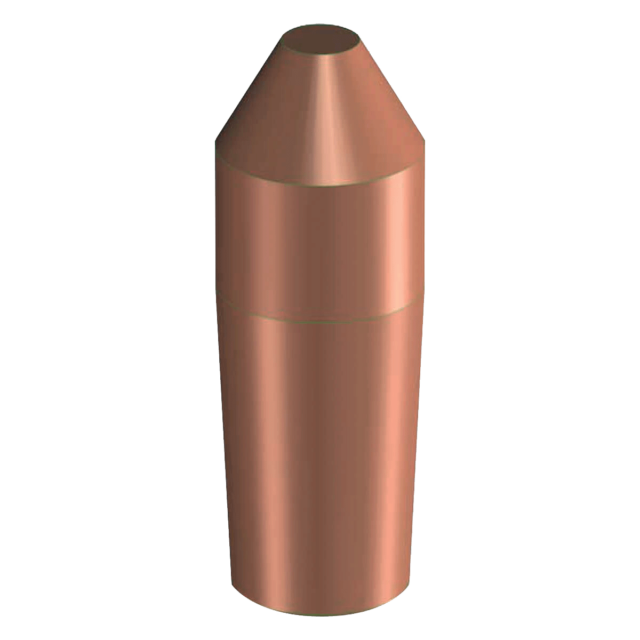

Set of 6 standard electrodes – Ø 19 mm

Set of 6 standard electrodes – Ø 25 mm

2 step pedal (1st step: squeeze, 2nd step: welding)

| TECHNICAL DATA | PPN 63 | PPN 83 | PPN 103 | PPN 153 | PPN 253 | |

| Single phase input 50/60 Hz | V | 400 | 400 | 400 | 400 | 400 |

| Rated power at 50% | kVA | 50 | 80 | 100 | 150 | 250 |

| Max. welding power | kVA | 113 | 210 | 293 | 460 | 610 |

| Installed power | kVA | 38 | 65 | 78 | 120 | 195 |

| Fuse(delayed action) | A | 100 | 150 | 200 | 300 | 500 |

| Secondary voltage | V | 5,9 | 8,3 | 9,4 | 11,5 | 12,5 |

| Secondary short circuit current | kA | 24 | 32 | 39 | 50 | 61 |

| Max welding current | kA | 19 | 25 | 31,2 | 40 | 49 |

| Work stroke | mm | 65 | 100 | 100 | 100 | 100 |

| Electrode force at 600kPa (6bar) | daN | 470 | 736 | 900 | 1200 | 1884 |

| Water consumption at 300 kPa (3bar) | l/min | 7 | 8 | 8 | 8 | 8 |

| Dimensions (LxWxH) | mm | 1070 x 430 x 1520 | 1115 x 400 x 1650 | 1115 x 400 x 1650 | 1170 x 400 x 1800 | 1210 x 460 x 1800 |

| Weight | kg | 335 | 560 | 580 | 610 | 900 |

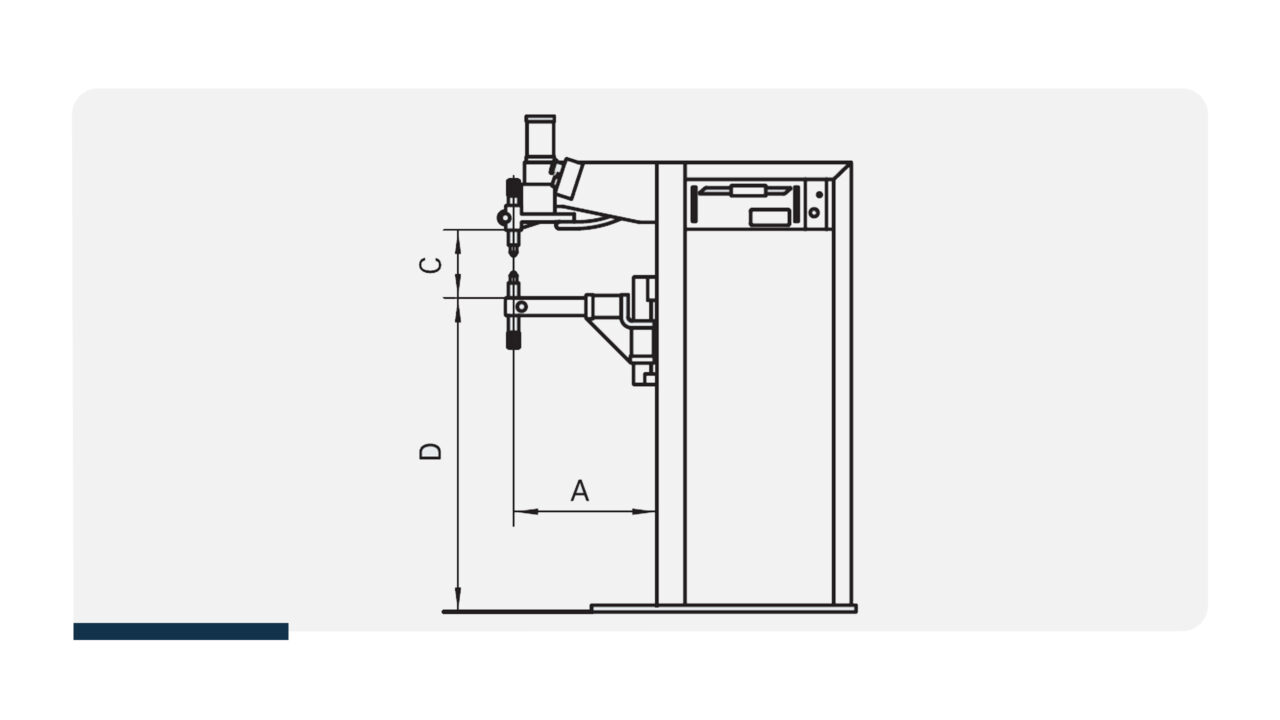

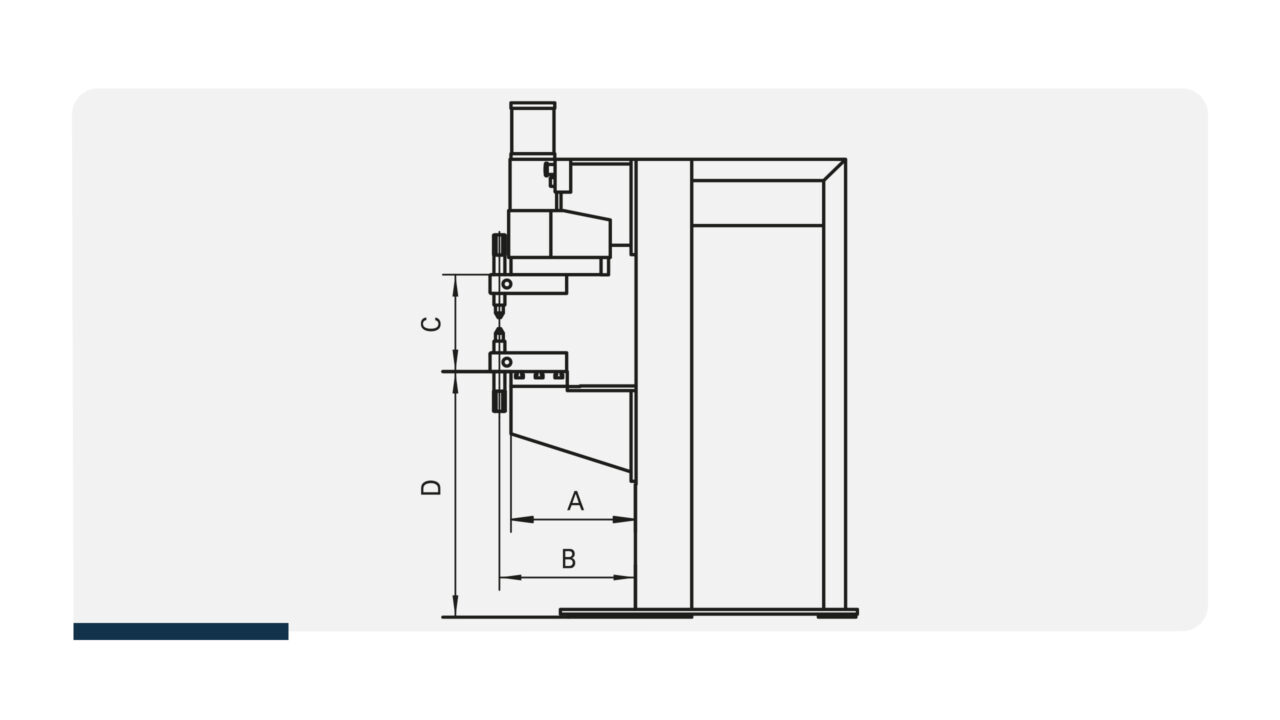

| PPN 63 | ||

| A | mm | 435 |

| A (Optional) – MIN. | mm | 650 |

| A (Optional) – MAX. | mm | 750 |

| C – MIN. | mm | 180 |

| C – MAX. | mm | 510 |

| D – MIN. | mm | 615 |

| D – MAX. | mm | 945 |

|

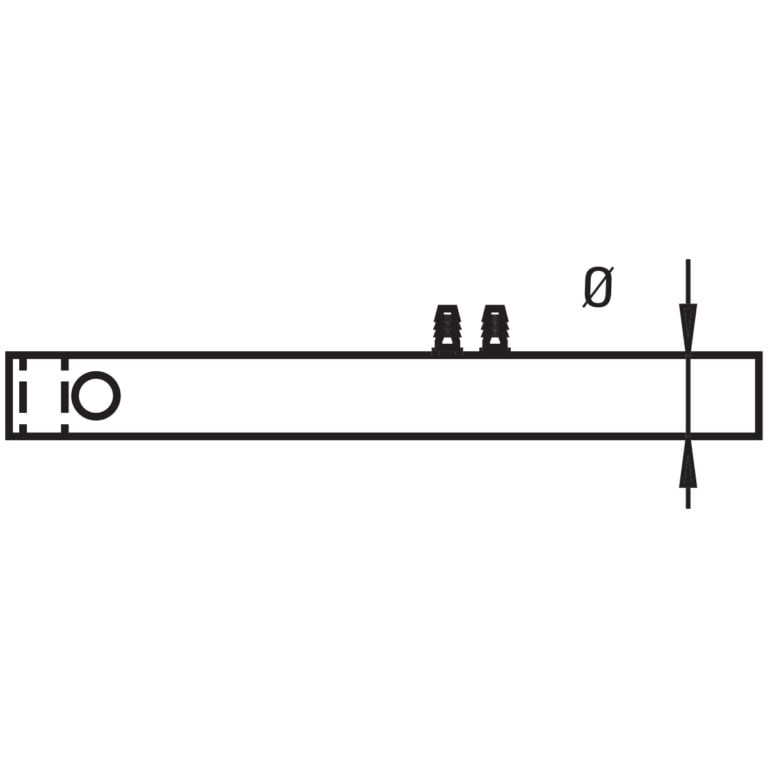

Ø mm | 60 |

|

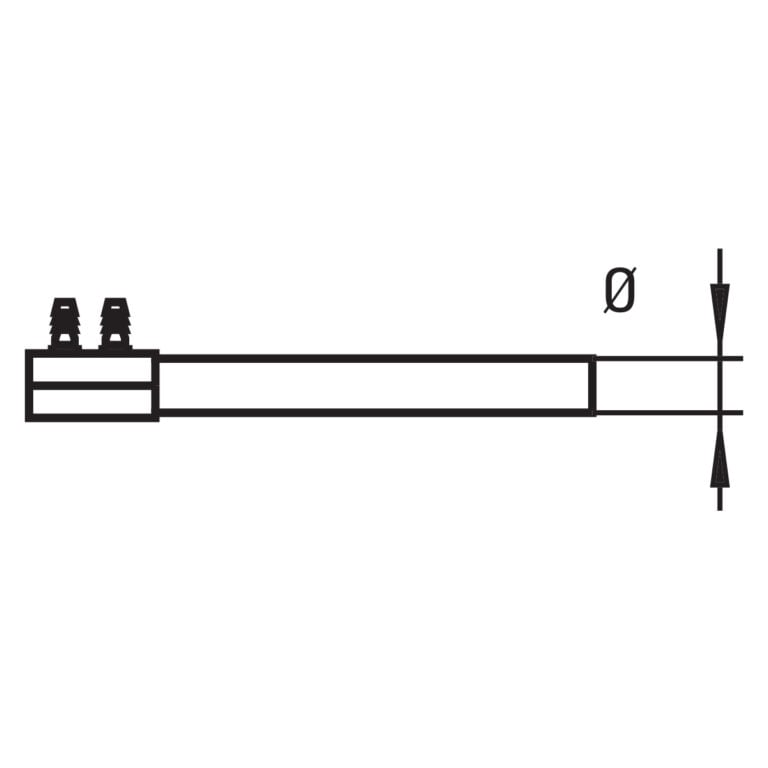

Ø mm | 35 |

|

Ø mm | 19 |

| PPN 83 | PPN 103 | PPN 153 | PPN 253 | ||

| A | mm | 400 | 400 | 400 | 445 |

| A (Optional) – MIN. | mm | 650 | 650 | 650 | 650 |

| B | mm | 445 | 445 | 445 | 490 |

| C – MIN. | mm | 145 | 145 | 145 | 200 |

| C – MAX. | mm | 300 | 300 | 300 | 330 |

| D – MIN. | mm | 800 | 800 | 800 | 865 |

| D – MAX. | mm | 955 | 955 | 955 | 995 |

| PPN 83 | PPN 103 | PPN 153 | PPN 253 | ||

|

Ø mm | 30 | 30 | 30 | 35 |

|

Ø mm | 19 | 19 | 19 | 25 |

|

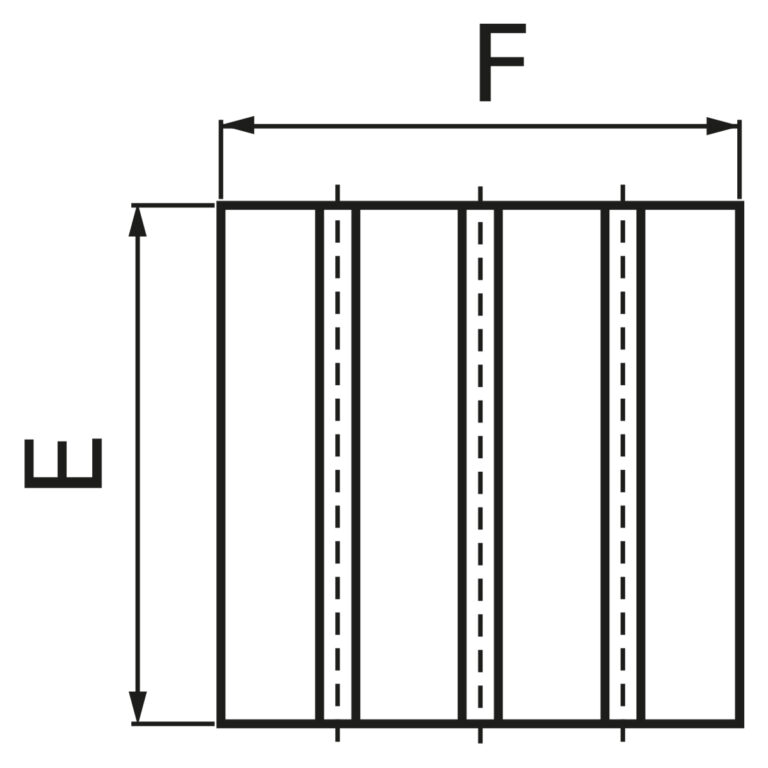

E mm | 150 | 180 | 180 | 200 |

| F mm | 150 | 180 | 180 | 200 | |

|

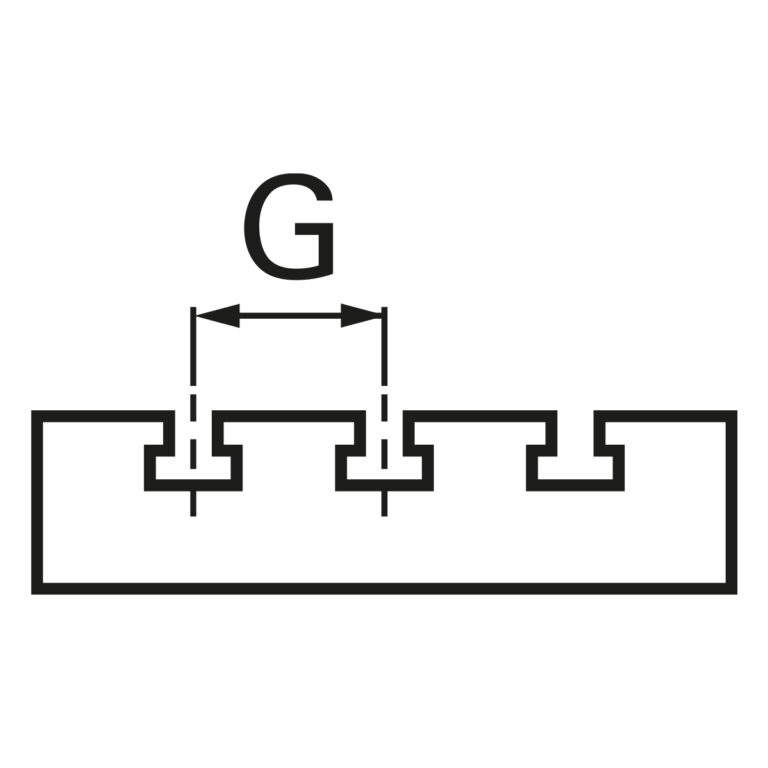

G mm | 63 | 63 | 63 | 63 |

|

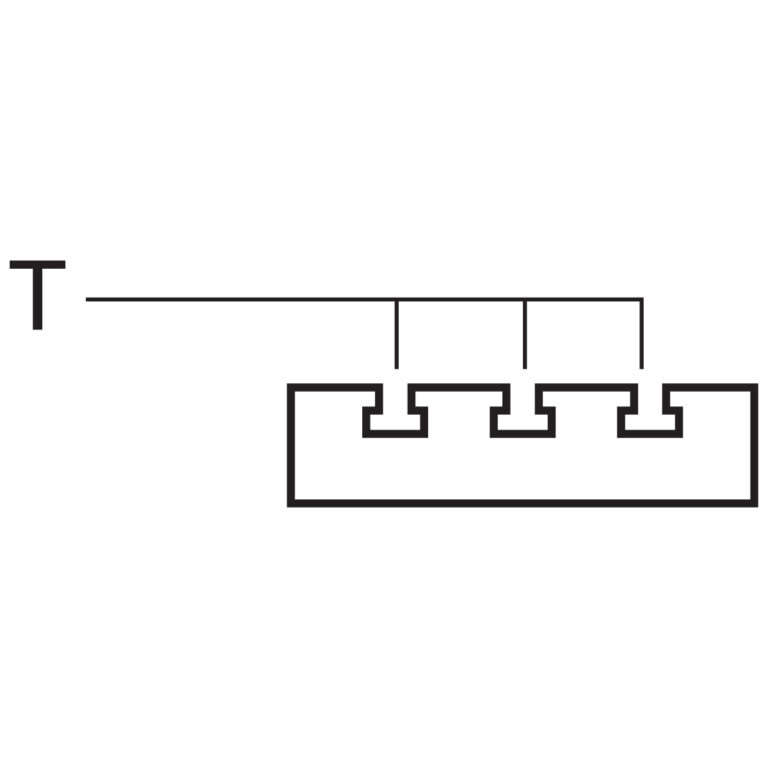

T | 2 | 3 | 3 | 3 |