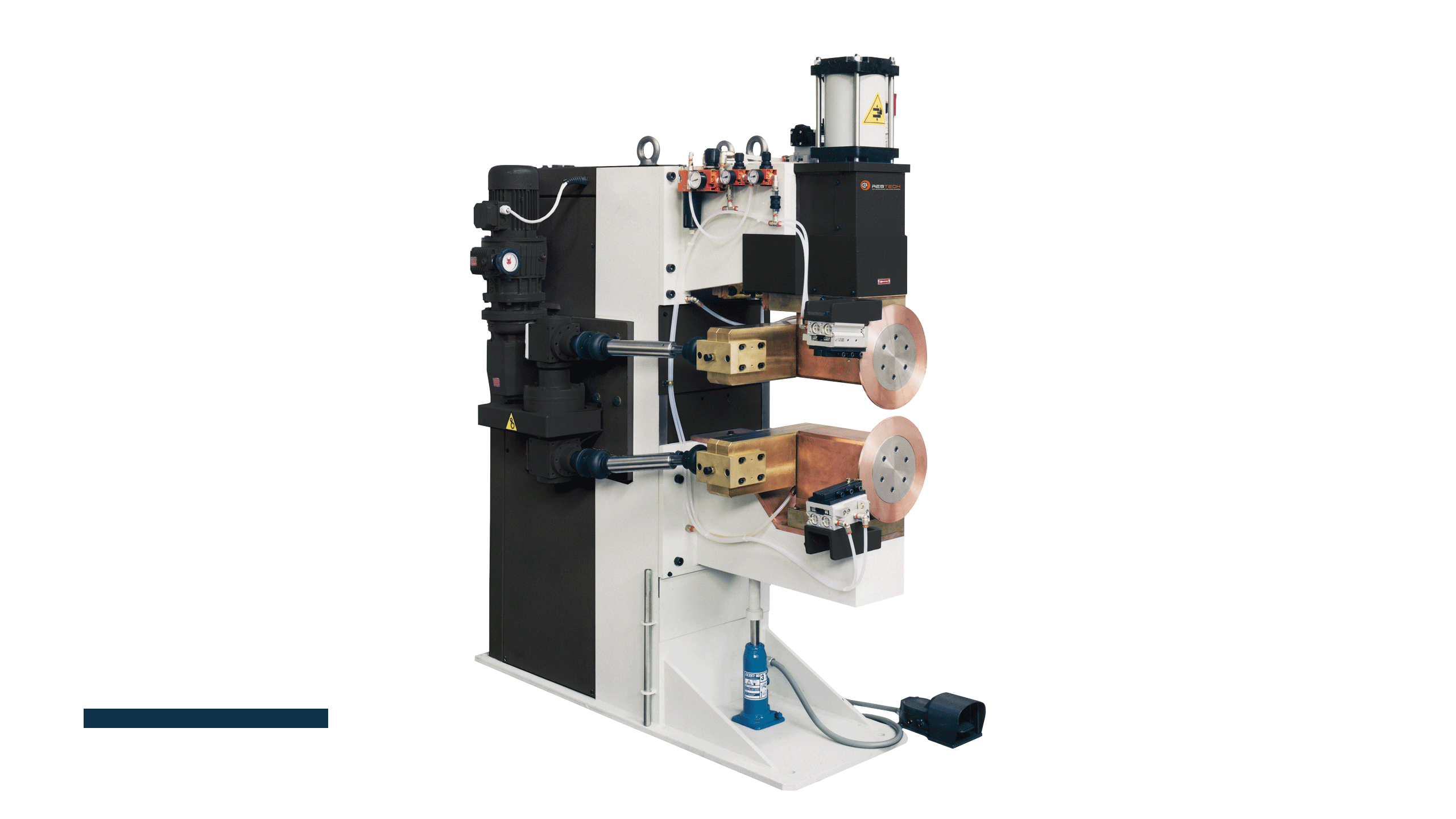

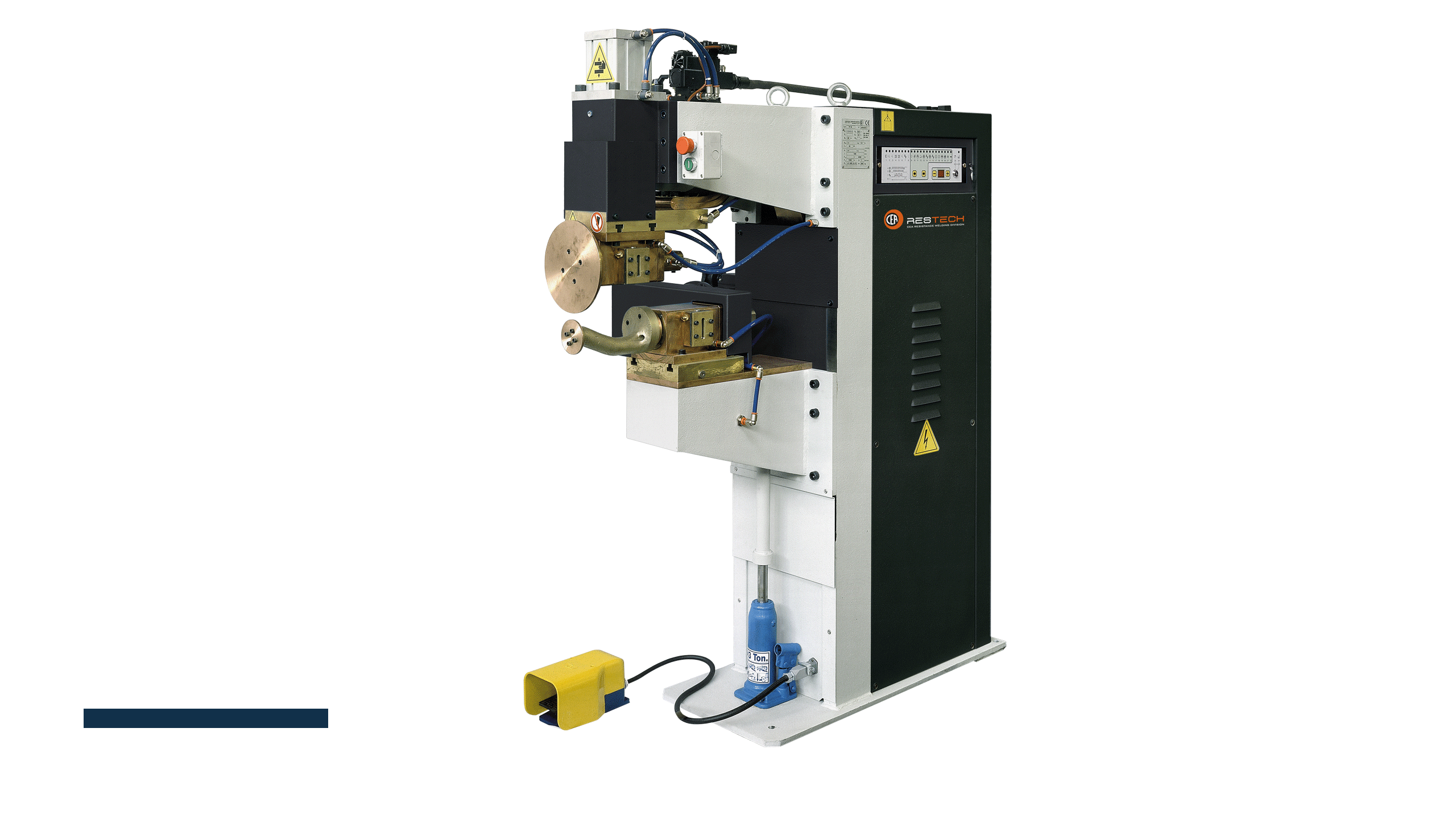

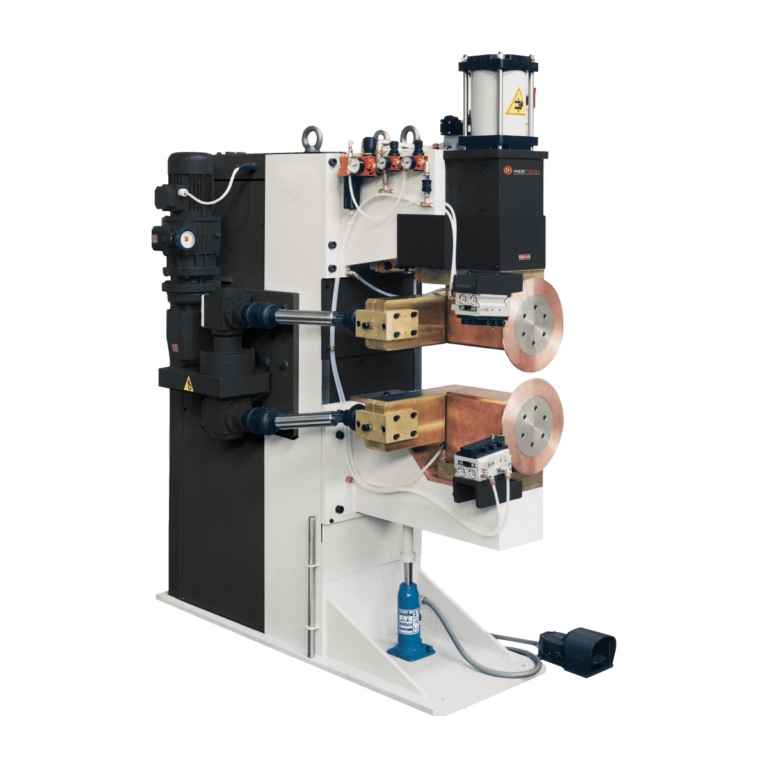

RT - RL

SEAM RESISTANCE WELDING

ENABLES TO OBTAIN WATER TIGHT SEAM WELDING

RT – RL Seam welders range are standard supplied for monophase mains connection. Three phase versions, also with Medium Frequency inverter (1000 Hz), are available for special applications. Medium frequency machine grants high speed welding and enables to join hardly weldable parts with reduced deformation. The wide range of the equipment configurations enables to obtain water tight seam welding of cylinders, fire estinguishers, radiators, tanks and similar items with excellent quality results.

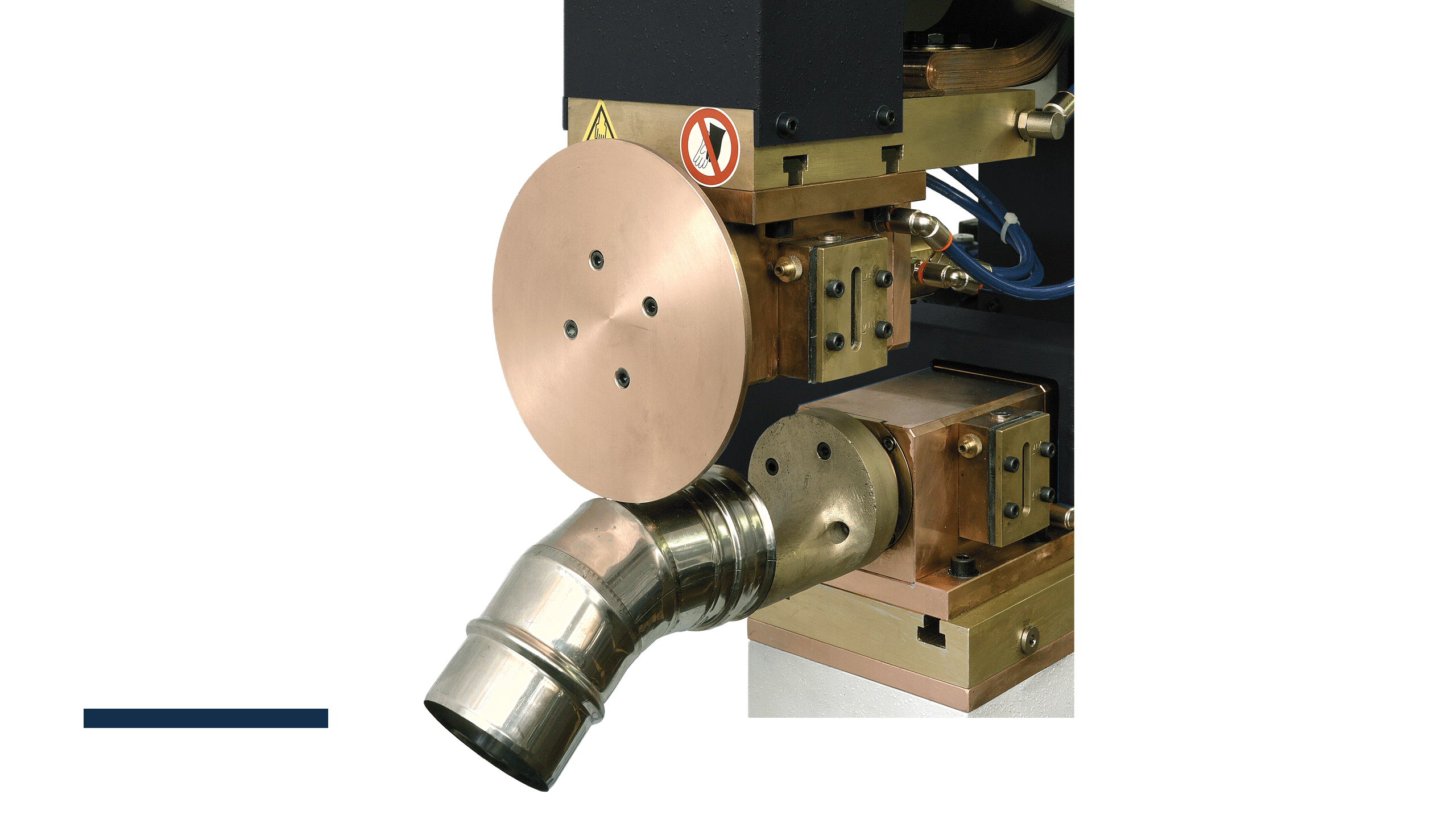

Seamwelding technology

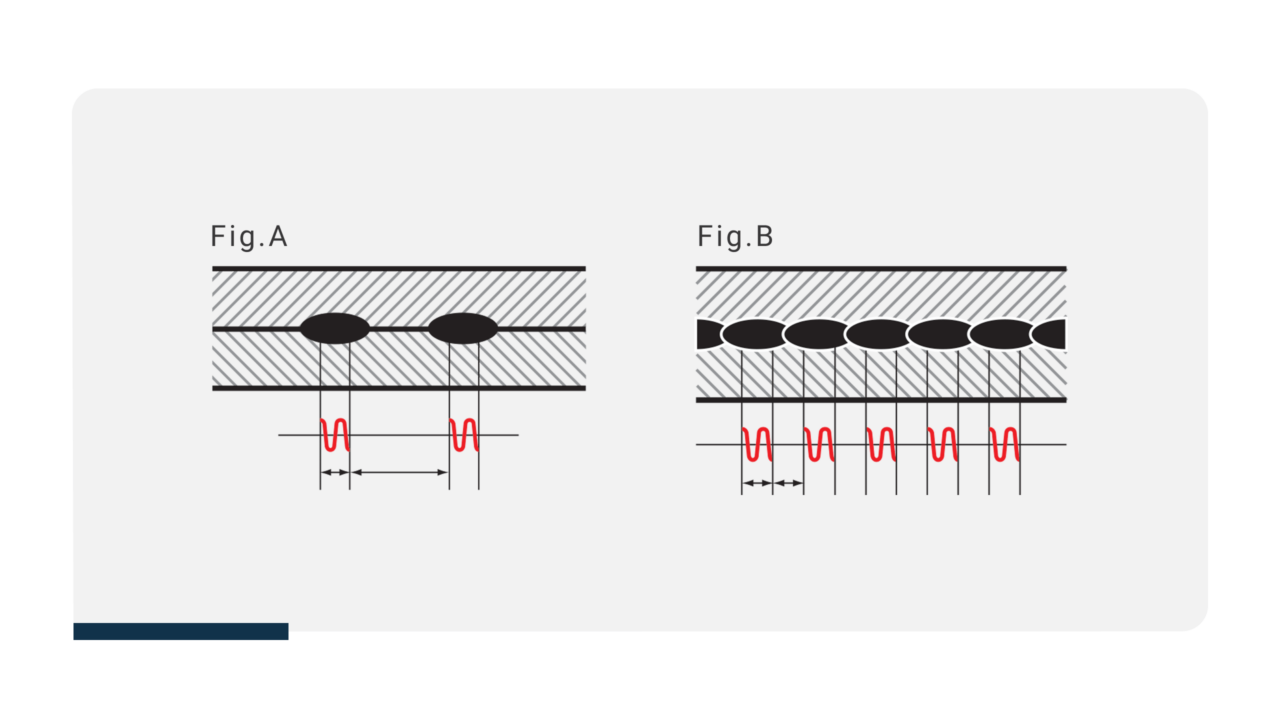

Seam welding is a welding process by electric resistance. In such joining process overlapped metals are welded under pressure by a sequence of spots made by copper alloy rotating discs. Depending on the choice of the parameters, such as spot frequency and rotation speed of the electrodes, two typical joints are usually achieved.

- Fig. A represents the welding pattern made by choosing a short welding time with a long pause time. This is for joining two metals without water tight welding.

- Fig. B shows the welding pattern made by adjusting welding and pause times in a way that each spot is overlapped by the next one. This joint allows water tight welding.

Other characteristics

- RT version for transversal welding only

- RL version for longitudinal welding only

- Water cooled seam heads with silver contacts, ensuring a good current transmission from the static part to the shaft

- Reduced maintenance costs

- Self-lubricated pneumatic components to eliminate oil deposits and to safeguard the environment from contaminants

- Frequency converter to adjust the welding speed of the discs

Gallery

RT - RL at work

Datasheet

RT - RL: Technical features

| TECHNICAL DATA | RT 80 | RT 80 2T | RT 81 | RT 180 2T | RL 81 | |

| Single phase input 50/60 Hz | V | 400 | 400 | 400 | 400 | 400 |

| Rated power 50% | kVA | 60 | 60 | 80 | 180 | 80 |

| Installed power | kVA | 60 | 60 | 80 | 180 | 80 |

| Fuse(delayed action) | A | 150 | 150 | 200 | 400 | 200 |

| Open circuit voltage | V | 5,1 | 5,1 | 6,7 | 9,5 | 6,7 |

| Throat depth | mm | 450 | 450 | 800 | 450 | 800 |

| Work stroke | mm | 80 | 80 | 80 | 100 | 80 |

| Electrode force at 600kPa(6bar) | daN | 470 | 470 | 470 | 1200 | 470 |

| Max welding capacity on mild steel | mm | 1,2 + 1,2 | 1,2 + 1,2 | 1,2 + 1,2 | 2 + 2 | 1,2 + 1,2 |

| Max welding capacity on stainless steel | mm | 1,5 + 1,5 | 1,5 + 1,5 | 1,5 + 1,5 | 3 + 3 | 1,5 + 1,5 |

| Dimensions (LxWxH) | mm | 1150 x 800 x 2020 | 1150 x 800 x 2020 | 1450 x 800 x 2100 | 1450 x 800 x 2100 | 1450 x 800 x 2100 |

| Weight | kg | 800 | 900 | 900 | 1540 | 900 |

| Drive head | A | A+B | B | A+B | B | |

| Driving system | C | E | D | E | D | |

| DRIVE HEAD | ||||||

| A = lower | ||||||

| B = upper | ||||||

| DRIVING SYSTEM | ||||||

| C = toothed belt | ||||||

| D = direct with hooke’s joint | ||||||

| E = differential | ||||||