Resistance welding

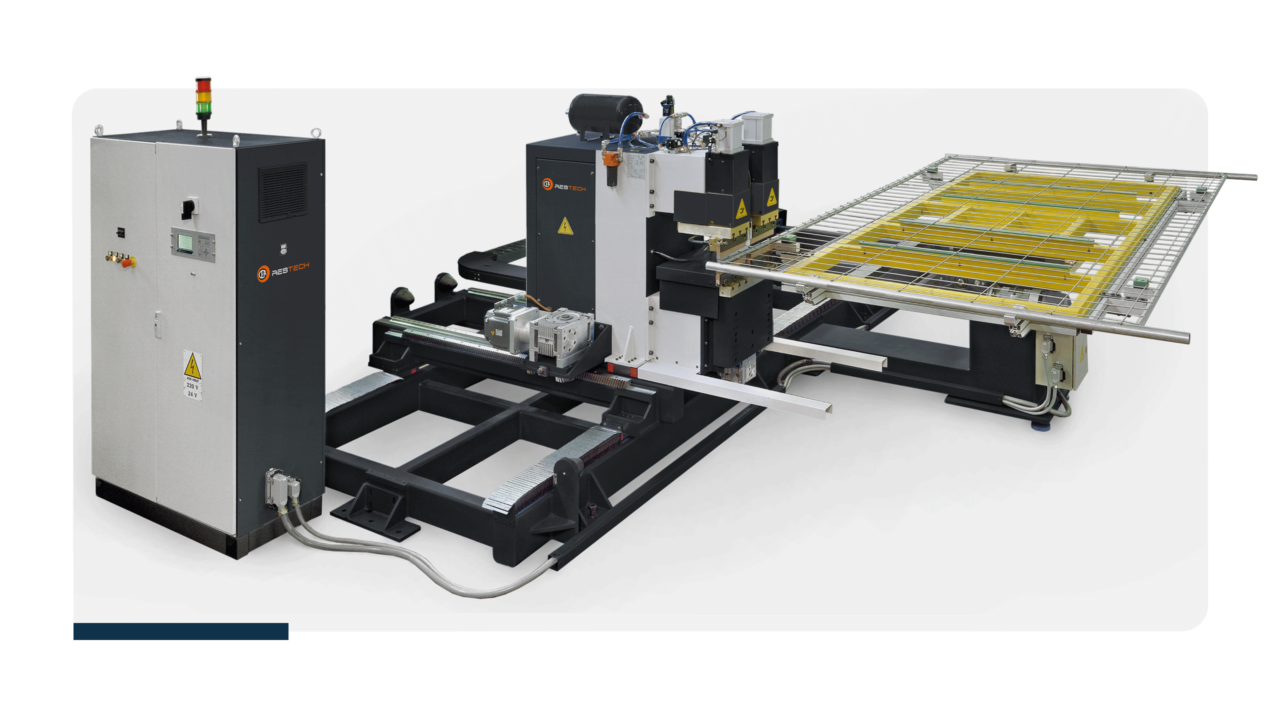

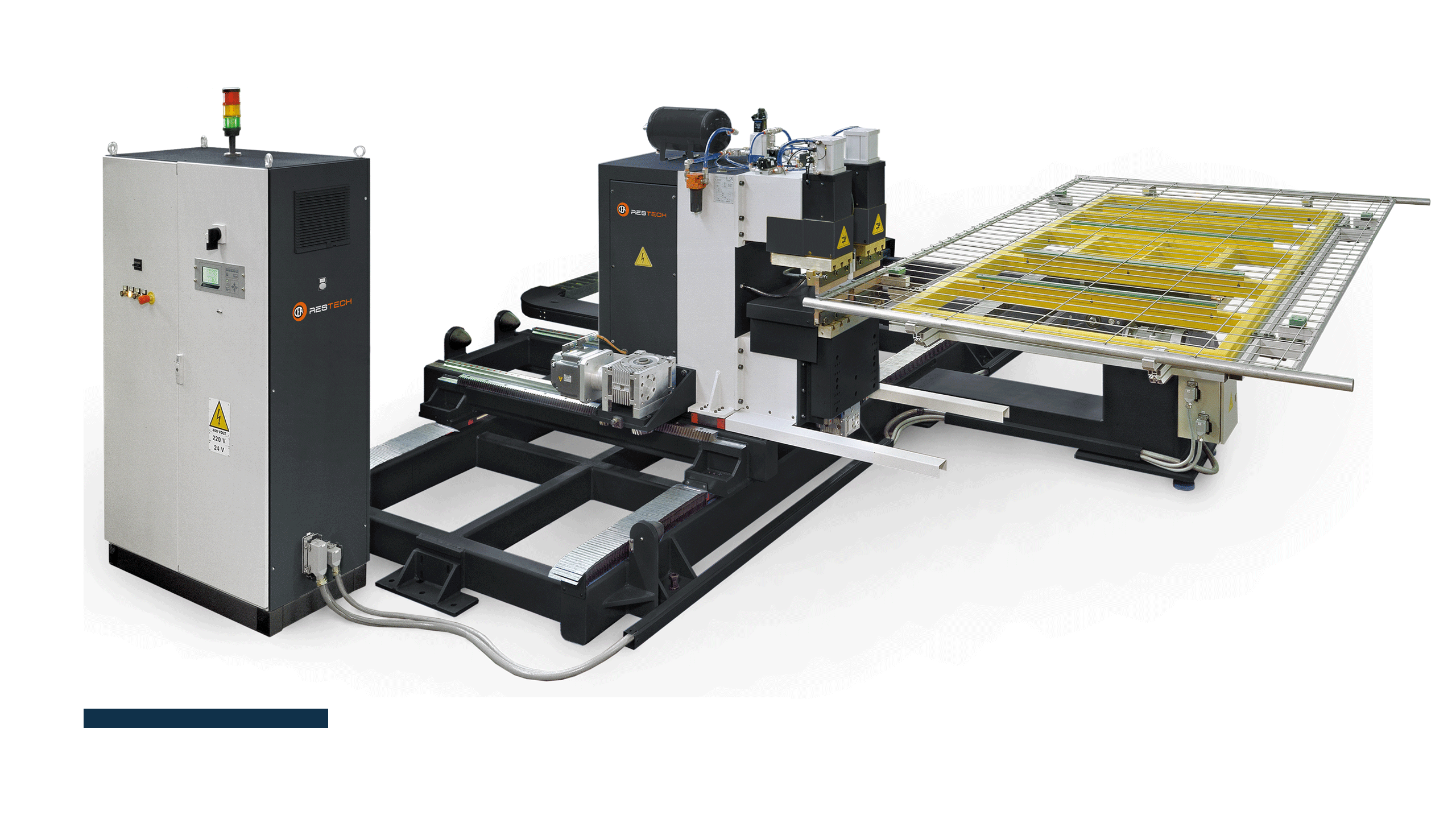

VOYAGER

ROBOTIC RESISTANCE SYSTEM

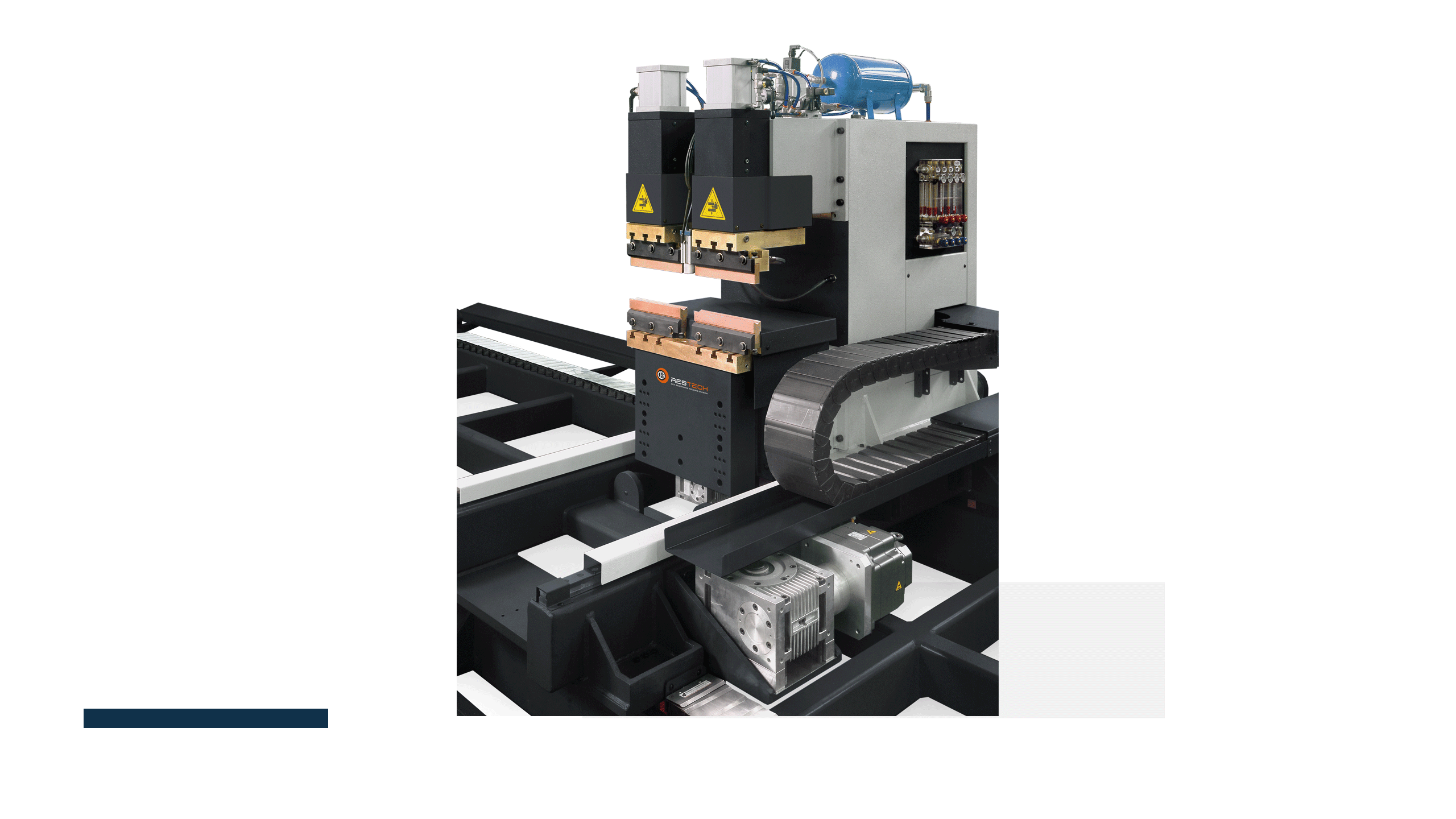

MULTI-AXIS RESISTANCE WELDING EQUIPMENT

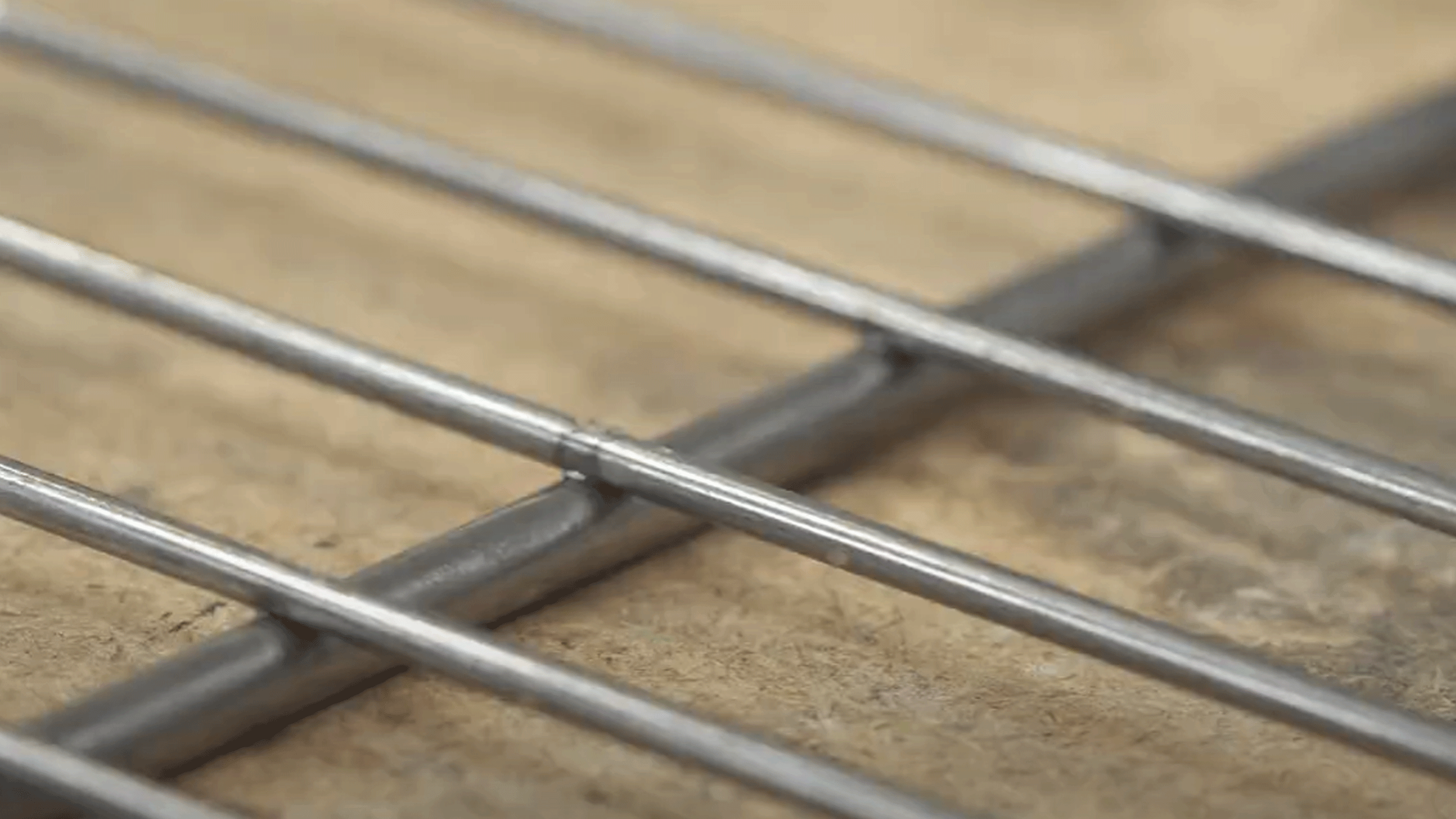

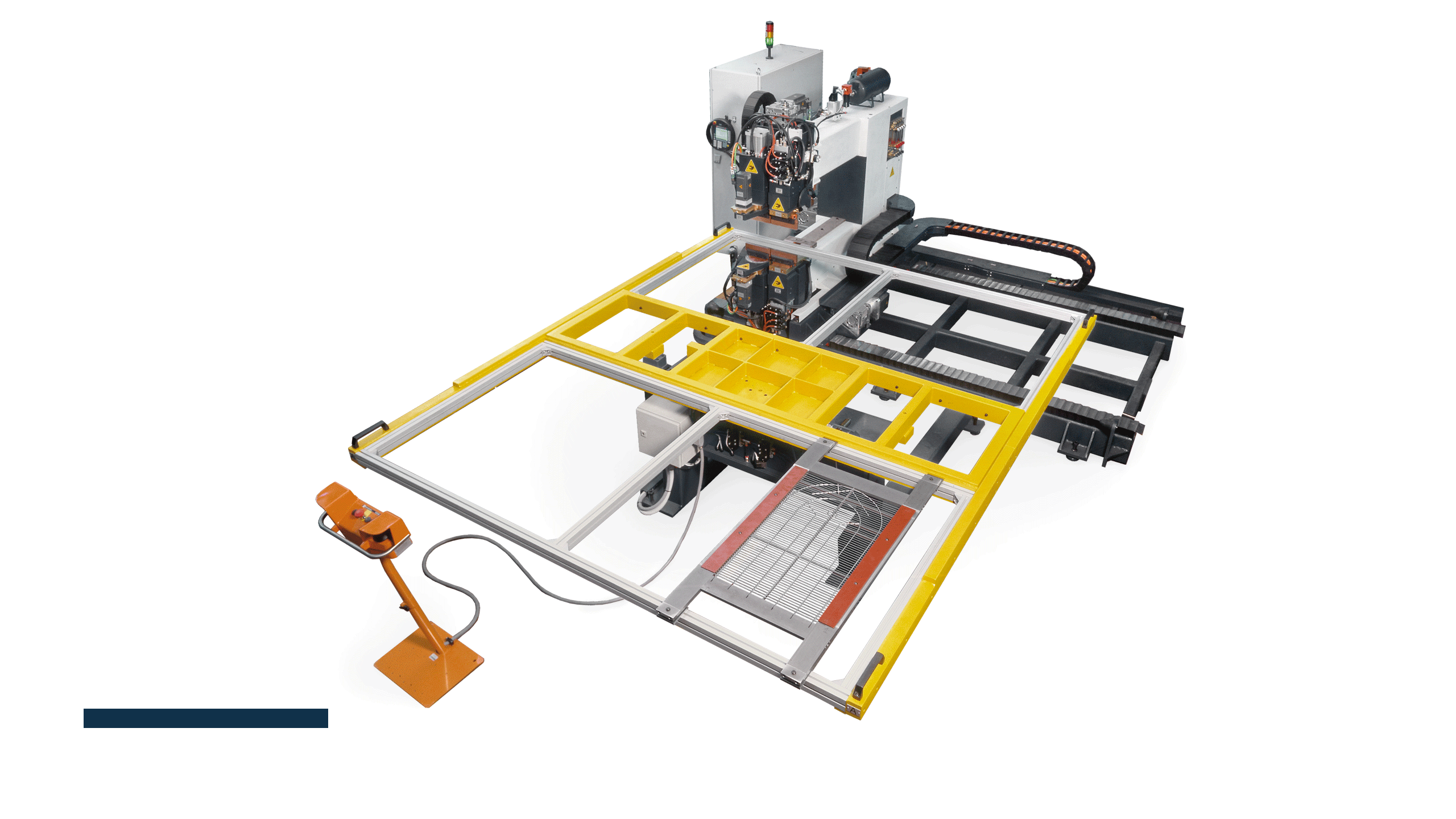

VOYAGER equipment is a robotized system working on more axes for resistance spot or projection welding of work pieces placed in proper jigs. Flexibility, productivity and easy programming are the main features of VOYAGER equipment, suitable also for small series mesh and of mild steel, stainless steel and aluminium lamination parts.

Equipment configuration

The equipment can be customized on customer’s needs. Several options are available.

- Welding mode:

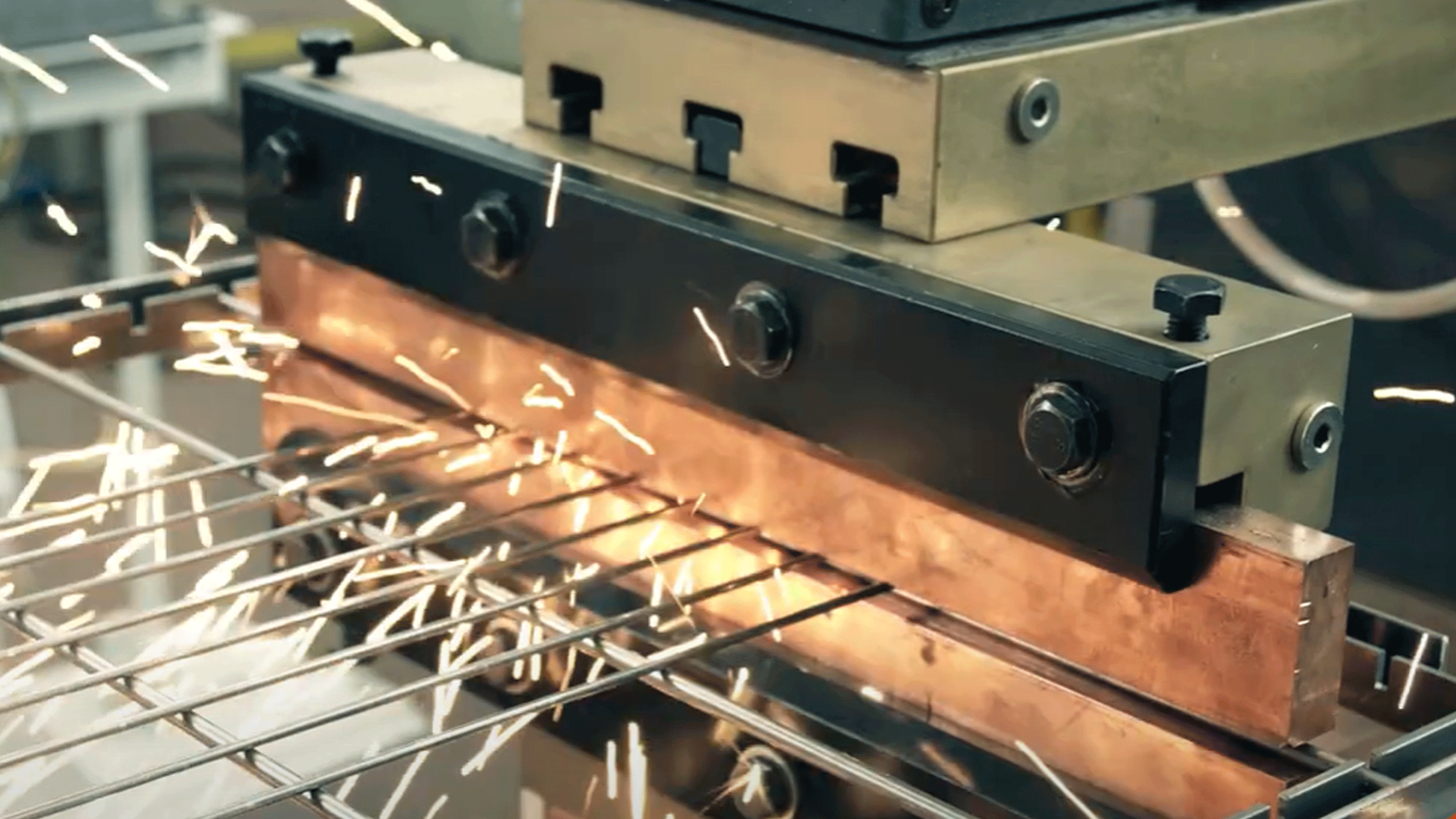

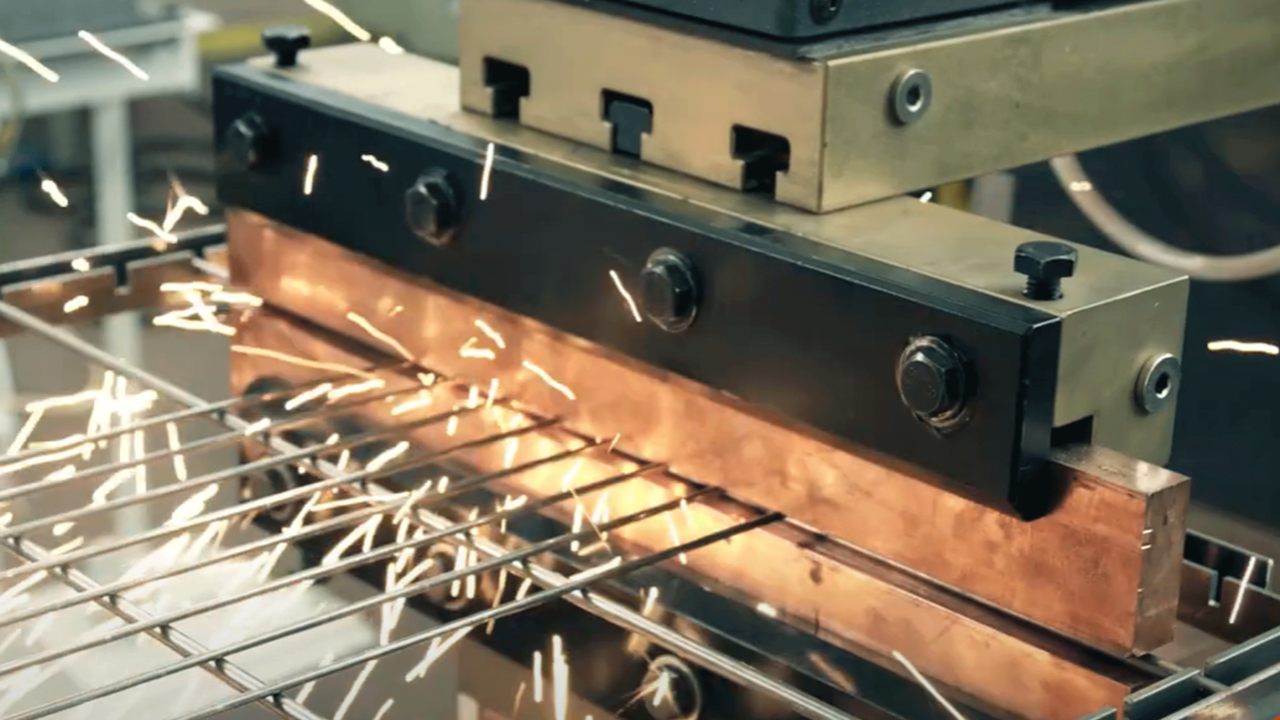

- Spotwelding

- Projection welding

- Welding technology:

- Medium Frequency inverter

- Traditional 50 Hz

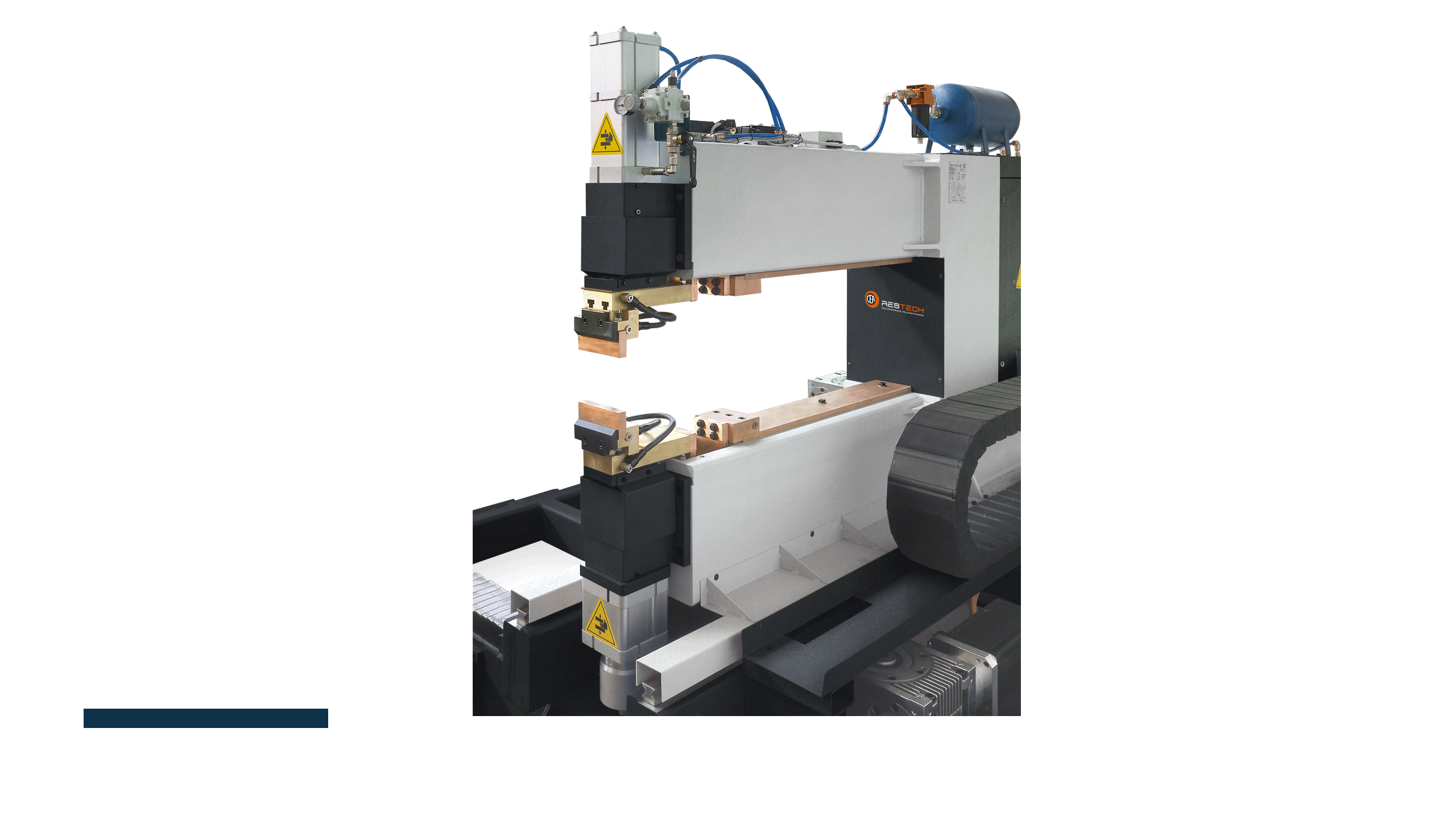

- Axis number

- Axis stroke length

- Welding head number

- Rotating electrodes (C1 – C2)

- Welding gun

Other characteristics

- Flexible programmable CNC system for positioning and welding at high and constant productivity.

- Easy programming thanks to CNC control teach-in function.

- Programmable independent welding parameters for each single spot.

- Possibility of welding at different heights thanks to programmable axes: Z1 (pre-stroke of upper electrode) and Z2 (stroke of the lower counterelectrode).

- Easy-to-operate and quick production shifting

- Shorter work cycle: workpiece loading/offloading during hidden time, by means of two station rotating table

- Working by servo operated brushless motors

- Robust and silent operation equipment