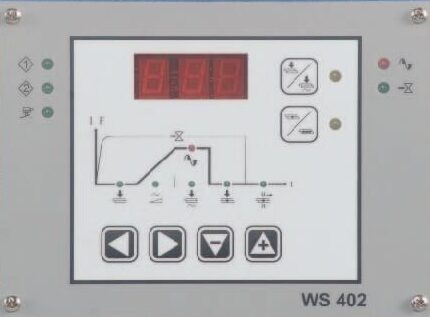

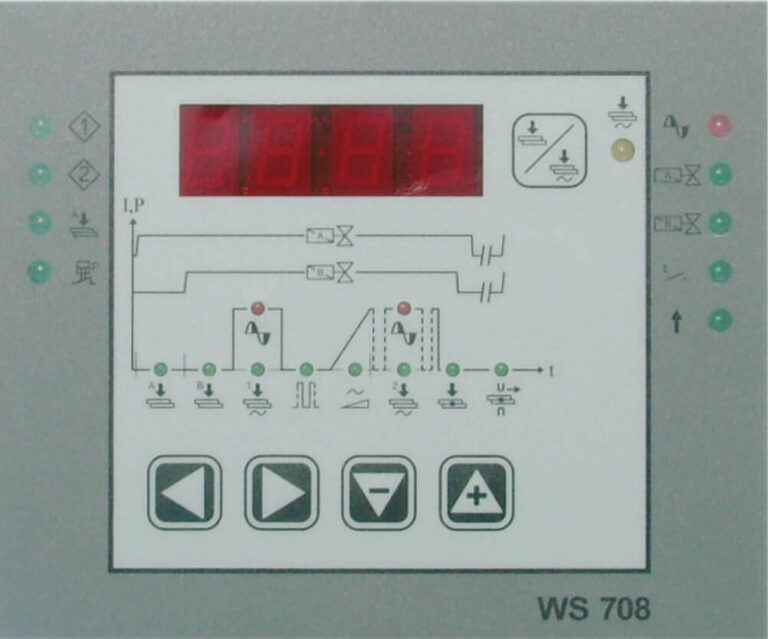

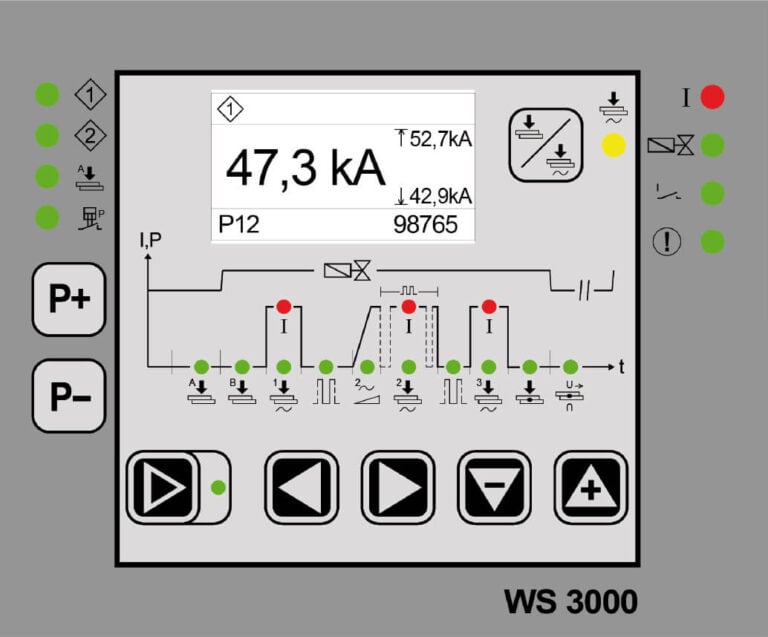

WS 750 is a microprocessor welding control for resistance welding machines with 100 programs/JOBs developed for spot, projection and butt-welding applications. The combination of 3 displays, 6 keys and LEDs allow a user friendly parameterization and configuration.

The LEDs have the function of showing the status of the welding cycle and to set the correct parameters of the welding JOB.

An USB port enables the backup of the welding JOBs, firmware updates and the saving of the welding logbook in Excel format.

WS 750 is available in 2 different configurations: STANDARD and ADVANCED.

WS 750 in STANDARD version allows to manage the main welding parameters for spot welding applications.

Additionally, the WS 750 ADVANCED allows to measure the welding current which enables the quality control of the cycle by selecting the min./max. current, and to adjust the welding force by using a proportional valve (optional).