Water cooling equipment HR 32 400 V

"*" indicates required fields

Powerful welding equipment in the size of just one wire feeder unit: this is the main peculiarity of CONVEX MOBILE series, innovative multiprocess synergic power sources for welding in MIG/MAG, MMA and TIG with “Lift” mode.

Versatile, easy-to-carry and user friendly, CONVEX MOBILE equipment are greatly appreciated, also thanks to their high technological conception, anywhere high quality welding is required and are ideal for on-site work, maintenance job, car body repair and light fabrication work.

CONVEX MOBILE PULSE, because of its additional Pulse and Dual Pulse processes, grants high quality performance on all materials and particularly on stainless steel, zinc coated and aluminium, by greatly minimizing any reworking job caused by spatters.

CONVEX MOBILE 201 and 205 PULSE, with single phase input power, have PFC facility which optimizes the amount of energy consumption by allowing their use, at maximum power, on 16 A fuse mains and with power generator sets without any problems.

Water cooling equipment HR 32 400 V

Cea CL-1100 cooling liquid – 5 l Tank

Trolley CT 401 with 4 rolls for power source, cooling equipment and cylinder

Adaptor support plate for CONVEX MOBILE mounted on CT 400

WK 2 extra-large wheel kit

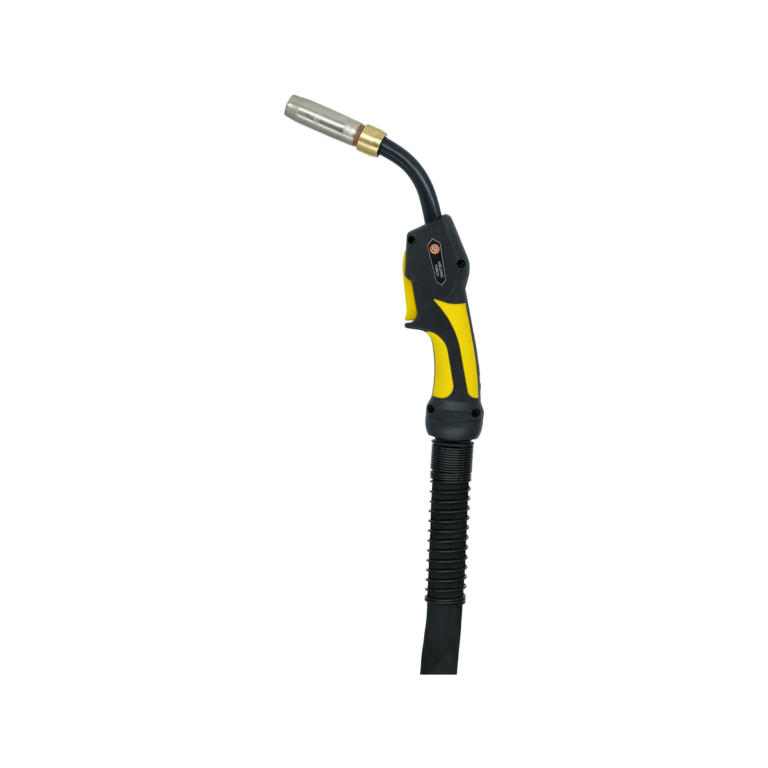

CEA Torch CX 251/3 3 m wire Ø 0.6÷1.0 CO2 260A @60% / Mix 200A @60%

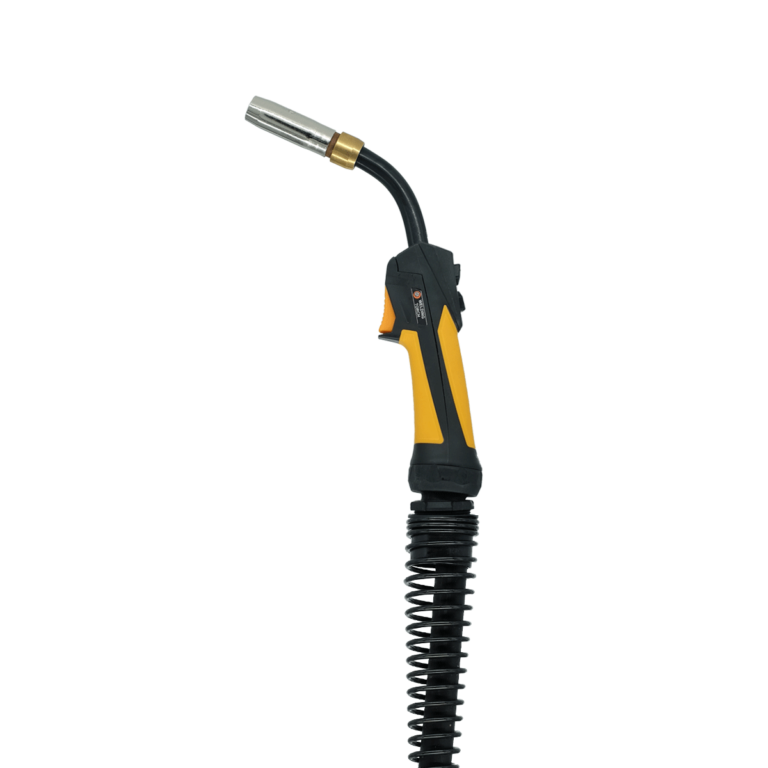

CEA Torch CXH 302/4 4 m wire Ø 0.8÷1.2 water cooled CO2 300A @100% / Mix 250A @100%

CEA Torch CXH 302/4 Up/Down-6p 4m – wire: Ø 0,8÷1.2 – CO2 300A @100% / Mix 250A @100%

CEA Torch CX 353/4 Up/Down-6p 4m – wire: Ø 0,8÷1.2 – CO2 340A @60% / Mix 290A @60%

CEA Torch RTX 26.4 4 m – 180 A 35%

35 mm² / 4 m Ground cable with clamp

Reducer with flowmeter and 1 manometer