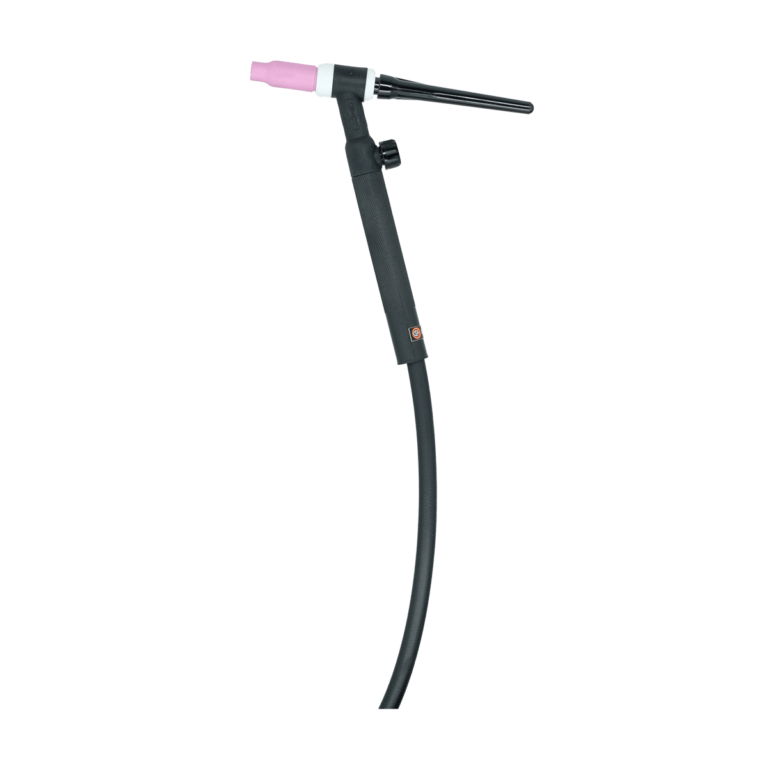

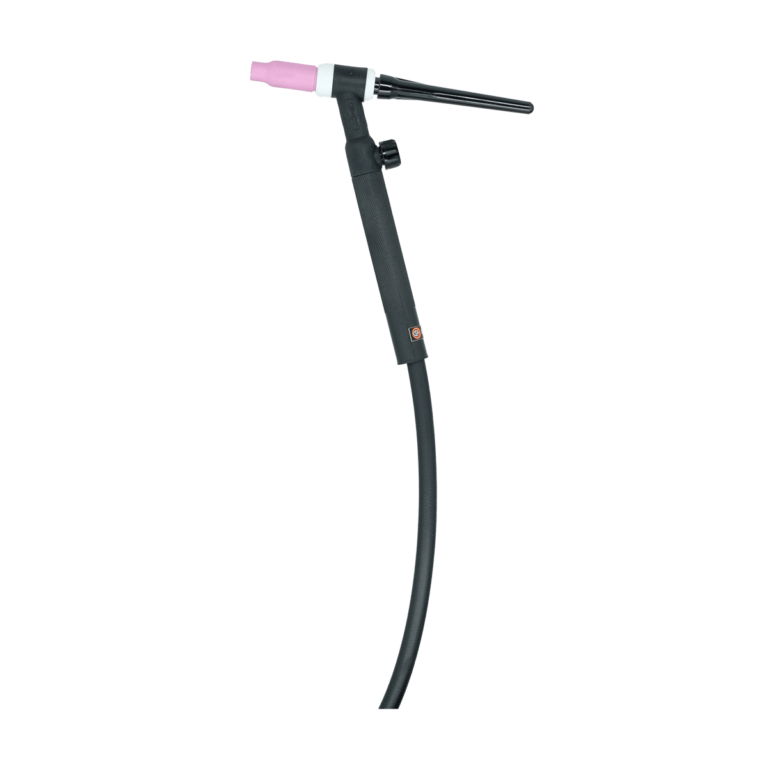

CEA Torch RTX 17.4

CEA Torch RTX 17.4 4 m – 140 A 35%

"*" indicates required fields

PROJECT 2100, are DC inverter power sources, built-in and ergonomic and robust chassis standard equipped with a carrying belt for easy transportation.

CEA Torch RTX 17.4 4 m – 140 A 35%

Rainbow Bag