CEA Torch TXA 17.4 4 m – 140 A 60% (DC)

"*" indicates required fields

RAINBOW HF is the iconic welding machine that has introduced the innovative inverter technology for professional TG DC welding machines in a curved design.

Equipped with a digital control, these powerful 100 kHz power sources, based on IGBT technology and fitted with flat transformer, can be used for TIG welding of any metal, excluding aluminium and its alloys.

RAINBOW HF also very well performing in MMA welding, due to their lightness and portability, are the ideal solution for excellent quality welding in maintenance, assembly and light fabrication works.

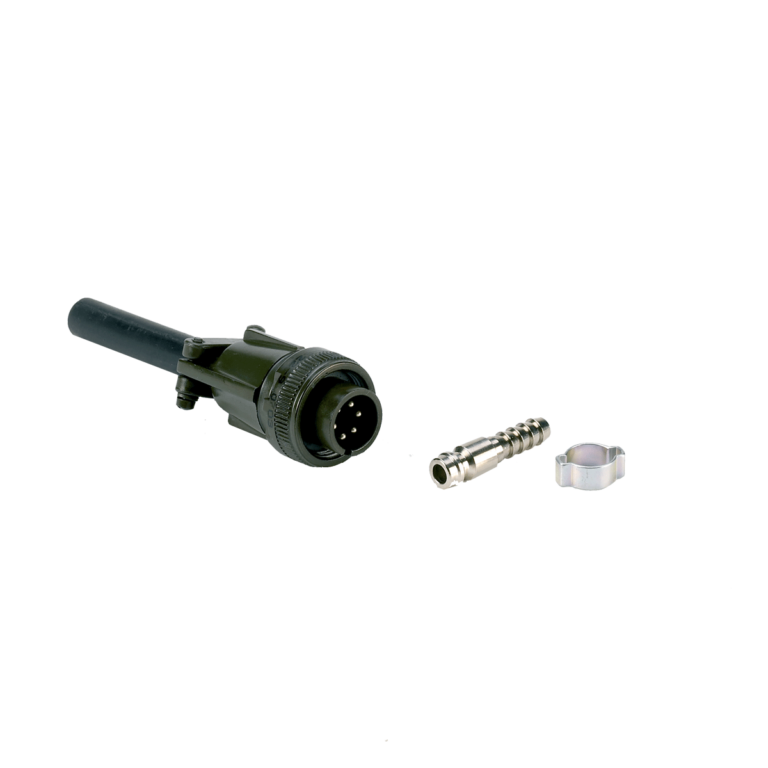

CEA Torch TXA 17.4 4 m – 140 A 60% (DC)

CEA Torch TXA 26.4 “UP/DOWN” 4 m – 250 A 60% (DC)

25 mm² / 3 m Ground cable with clamp

Reducer with flowmeter and 1 manometer

Rainbow Bag

Carrying Belt Kit

Adapter for simultaneous connection of Torch and PSR 7

A6 Connection kit for non-standard Torch