Water cooling equipment HR 22 230 V

"*" indicates required fields

MATRIX AC/DC are highly technologically advanced TIG power sources with a complete and user friendly interface for the total control of all welding parameters.

MATRIX AC/DC grants excellent TIG welding performance with all metals, including aluminum and its alloys, in the toughest industry and in maintenance application.

TIG DC min current from 1A / TIG AC min Current from 3 A

MATRIX AC/DC also offer excellent performance in MMA welding with the most difficult basic and cellulosic electrodes.

Water cooling equipment HR 22 230 V

Water cooling equipment HR 23 400 V

Cea CL-1100 cooling liquid – 5 l Tank

Trolley VT 101 with 2 rolls for power source, cooling equipment and cylinder

Trolley CT 401 with 4 rolls for power source, cooling equipment and cylinder

Trolley CT 70 with 4 rolls for power source, cooling equipment and cylinder (and autotransformer)

Trolley CT 75 with 4 rolls for power source, cooling equipment and cylinder (and autotransformer)

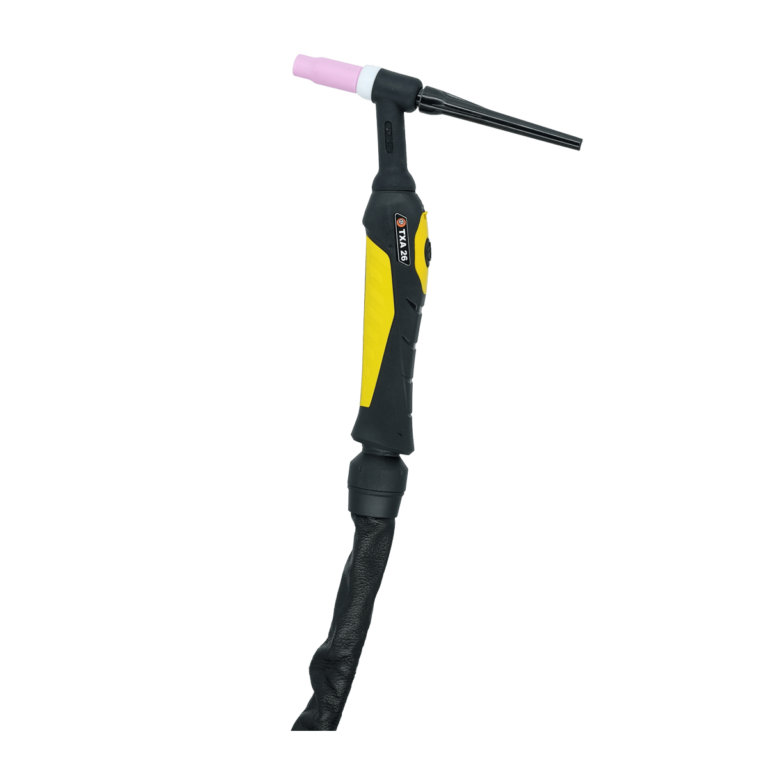

CEA Torch TXA 26.4 4 m – 250 A 60% (DC)

CEA Torch TXH 18.4 4 m – 320 A 100% (DC) – water cooled

CEA Torch TXH 18.4 “UP/DOWN” 4 m – 320 A 100% (DC) – water cooled

CEA Torch Mini TXH 20.4 4 m – 250 A 100% (DC) – water cooled

CEA Torch Mini TXH 20.4 “UP/DOWN” 4 m – 250 A 100% (DC) – water cooled

35 mm² / 4 m Ground cable with clamp

70 mm² / 4 m Ground cable with clamp

Reducer with flowmeter and 1 manometer

Adapter for simultaneous connection of Torch and PSR 7

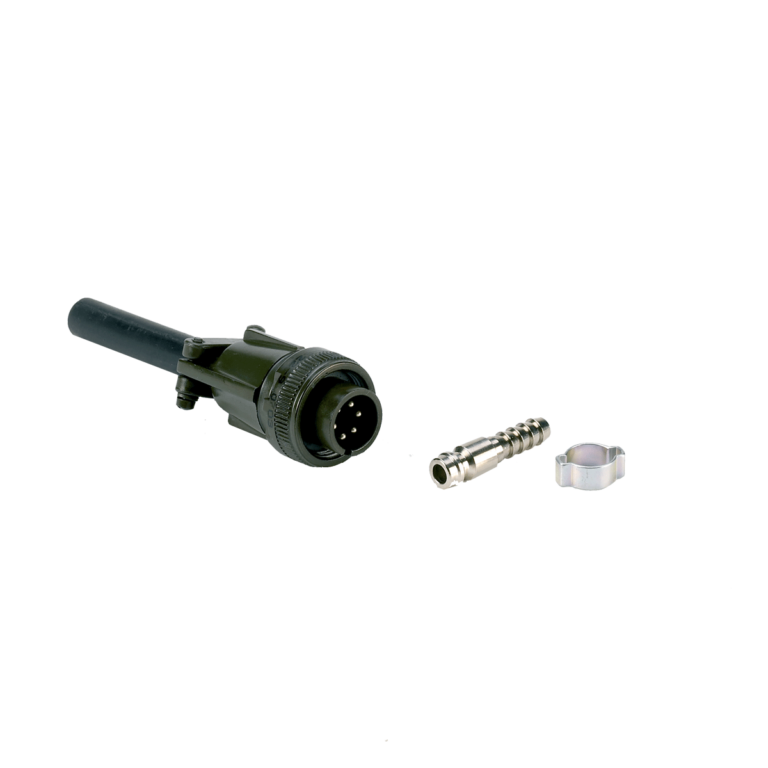

A6 Connection kit for non-standard Torch