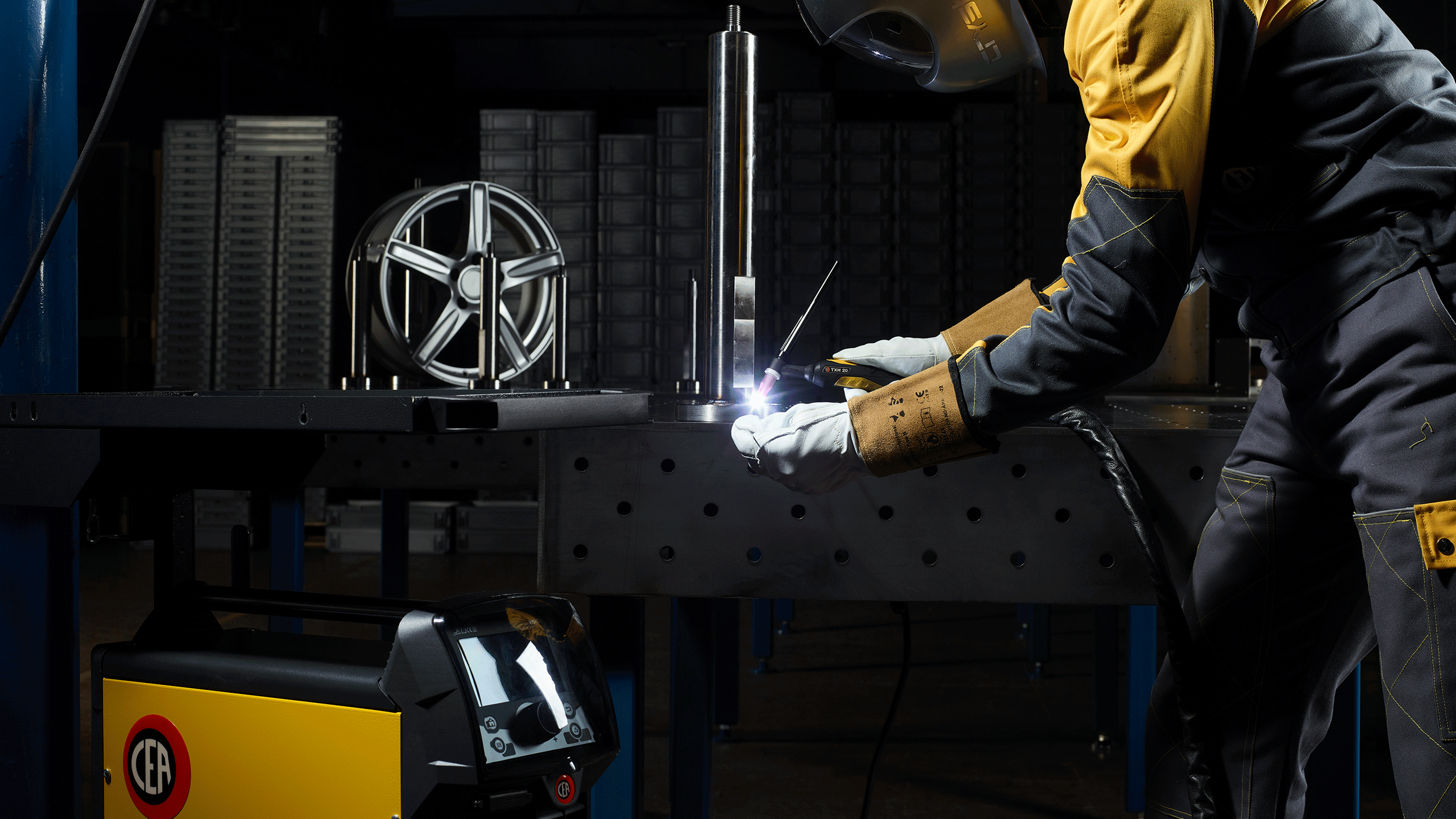

MATRIX X AC/DC

THE ULTIMATE SOLUTION FOR AC/DC TIG

TIG INVERTER WELDING EQUIPMENT

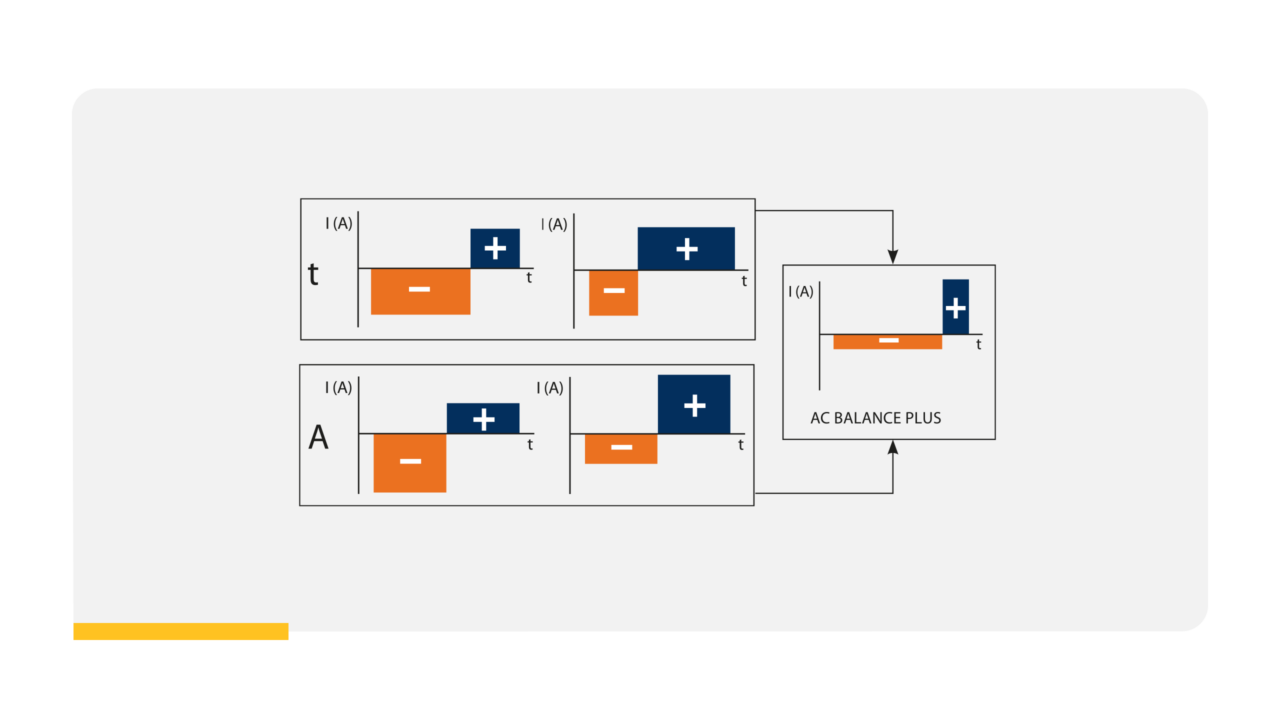

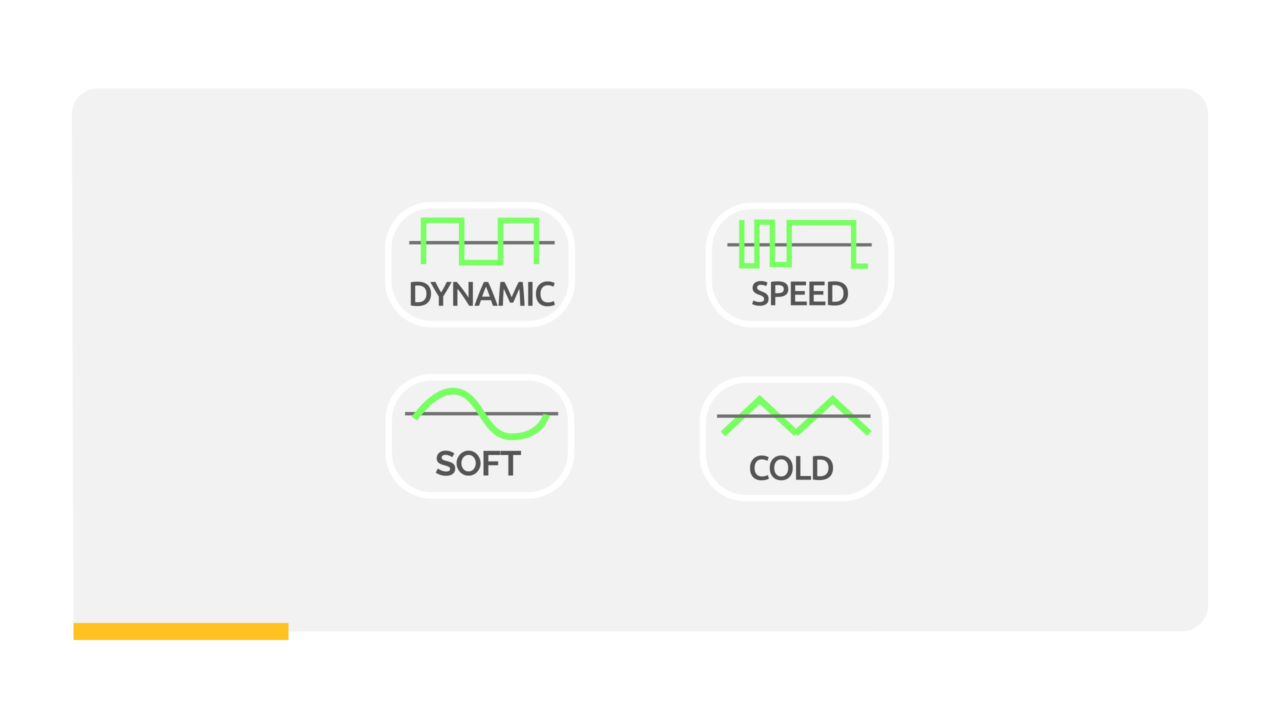

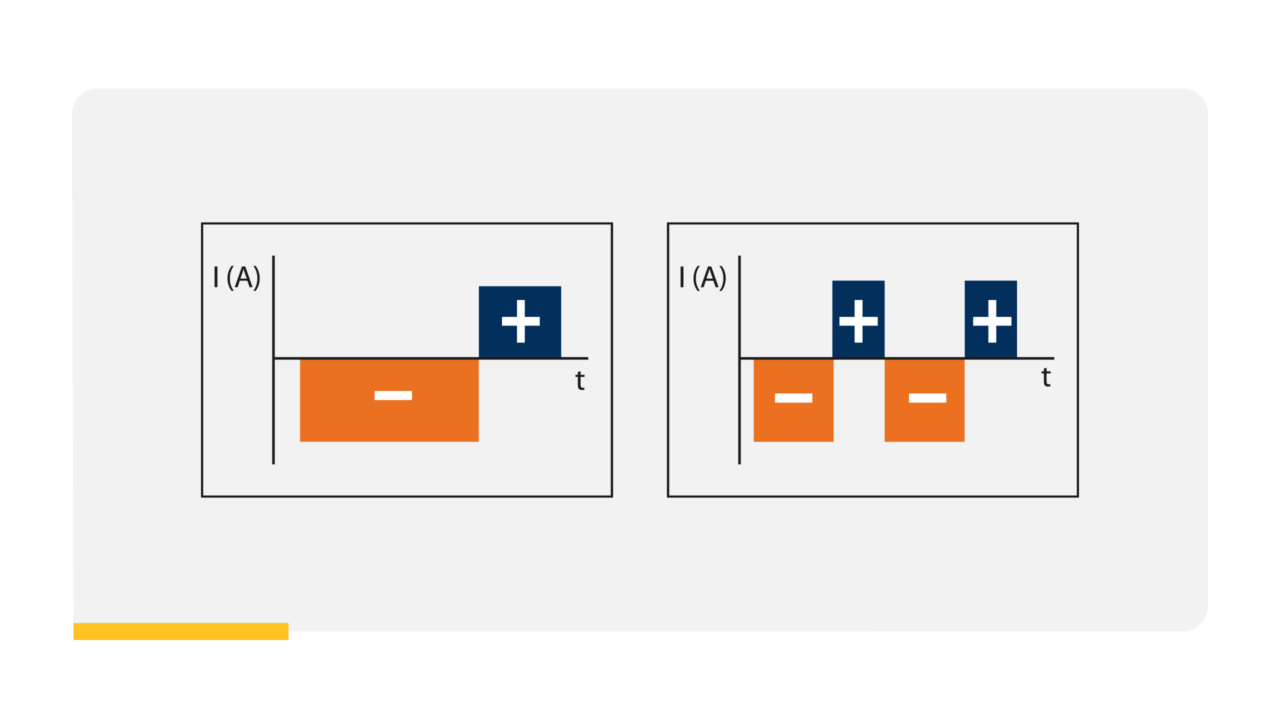

MATRIX X AC/DC are high efficiency TIG AC/ DC inverter power sources, studied to satisfy the most advanced and sophisticate request in the TIG welding market.

MATRIX X AC/DC enable TIG welding of all metals including Aluminium and its alloys, and they also offer excellent performance in MMA welding with the most difficult basic and cellulosic electrodes.

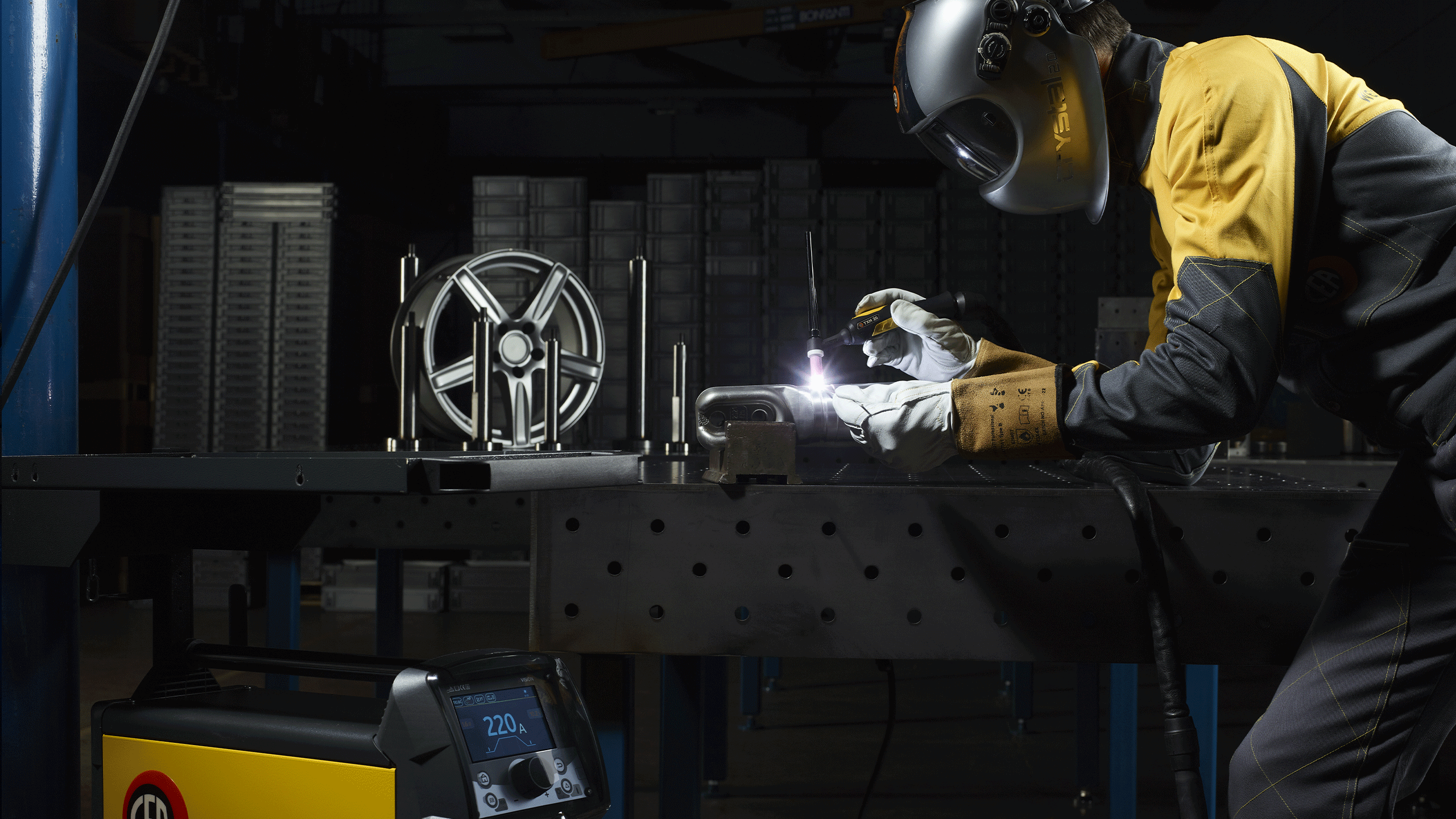

X Vision interface

MATRIX X AC/DC are standard equipped with the new X VISION interface, simple and complete, for the total control and monitoring of all the welding parameters.

TIG DC minimum current from 1A and TIG AC starting from 3A.

Excellent welding performance

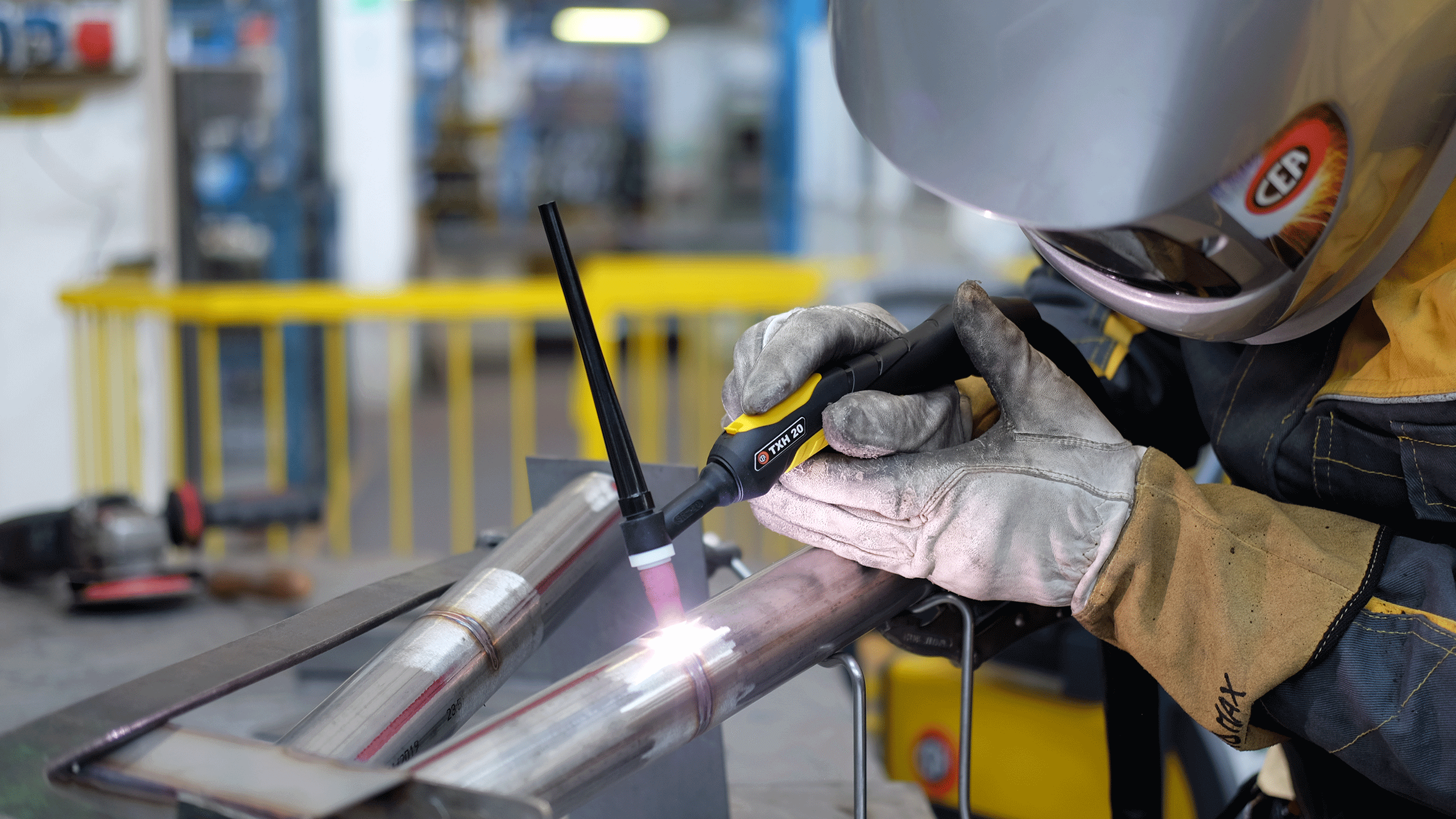

Their excellent characteristics, coupled with the high technology of the digital control, allow a perfect stability of the welding arc, granting high performance TIG welding in the more sophisticated industrial applications and maintenance.

Thanks to PFC the single phase MATRIX X 220 AC/DC optimizes the amount of energy consumption by allowing the use of this powerful power source, without problems, with 16 A fuse mains and power generator sets.

Other characteristics

- Excellent welding characteristics in TIG with all material and MMA with any type of electrodes, cellulosic included

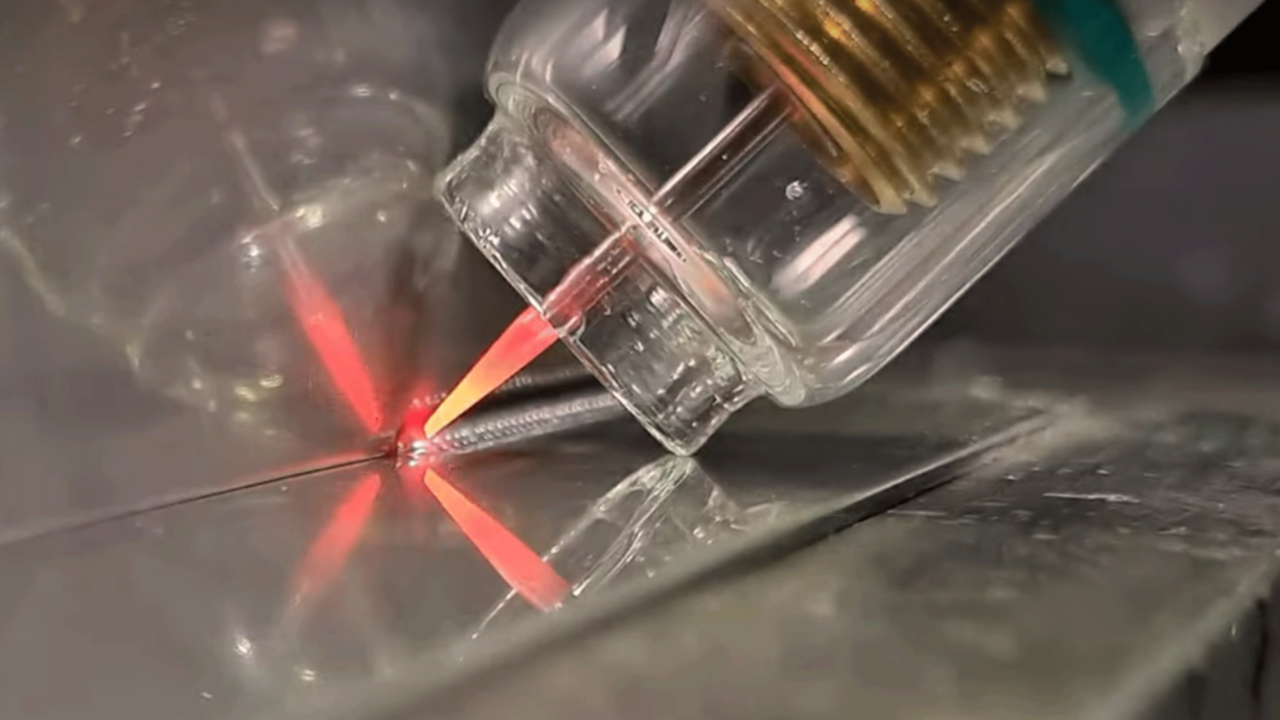

- Smart HF IGNITION for an accurate and prompter Arc Striking in all conditions

- Use of Up/Down TIG torches will enable to adjust welding parameters and JOBS

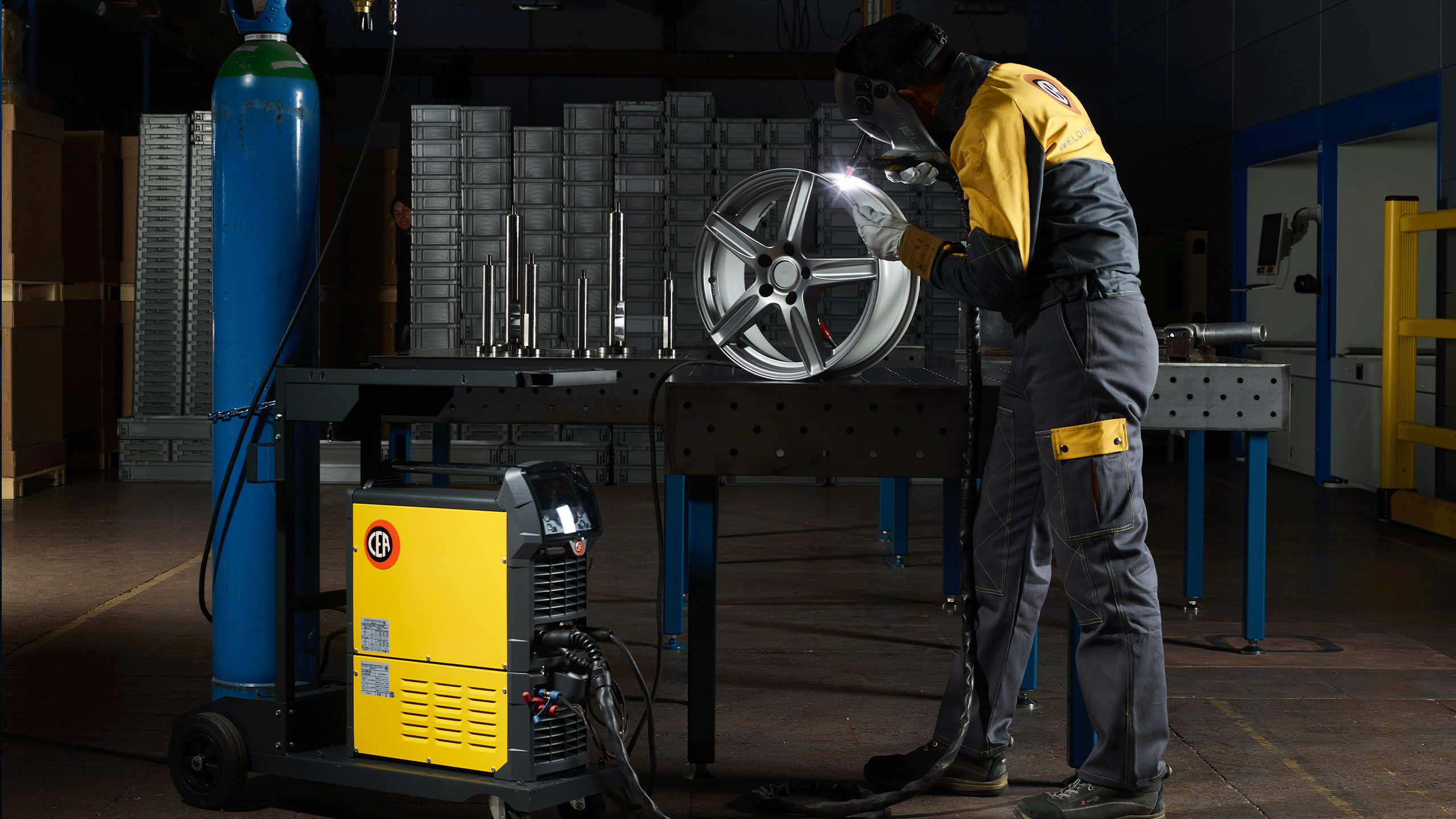

- Reduced weight and size, easy-to-carry

- Compact water cooling equipment integrable (optional)

- Simple automation: TSA1 (Optional)

Technical features

Available accessories

Discover all available accessories

Water cooling equipment HRX 30 400 V

Water cooling equipment HRX 52 400 V

Cea CL-1100 cooling liquid – 5 l Tank

Trolley VT 101 with 2 rolls for power source, cooling equipment and cylinder

Trolley CT 401 with 4 rolls for power source, cooling equipment and cylinder

Trolley CT 70 with 4 rolls for power source, cooling equipment and cylinder (and autotransformer)

Trolley CT 75 with 4 rolls for power source, cooling equipment and cylinder (and autotransformer)

Trolley CT 80 for power source, cylinder (and autotransformer)

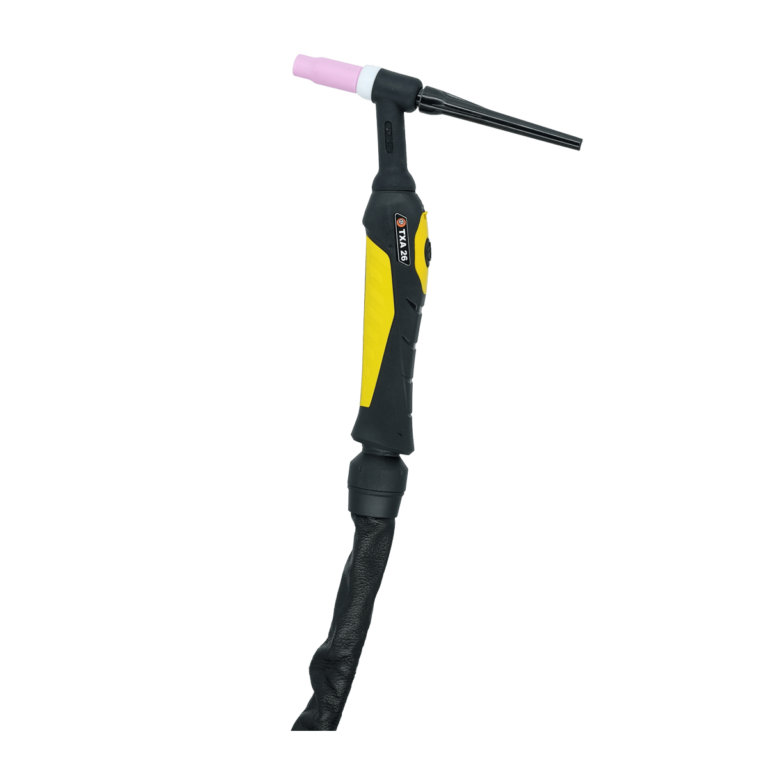

CEA Torch TXA 26.4 4 m – 250 A 60% (DC)

CEA Torch TXA 26.4 “UP/DOWN” 4 m – 250 A 60% (DC)

CEA Torch Mini TXH 20.4 4 m – 250 A 100% (DC) – water cooled

CEA Torch Mini TXH 20.4 “UP/DOWN” 4 m – 250 A 100% (DC) – water cooled

CEA Torch TXH 18.4 4 m – 320 A 100% (DC) – water cooled

CEA Torch TXH 18.4 “UP/DOWN” 4 m – 320 A 100% (DC) – water cooled

35 mm² / 4 m Ground cable with clamp

70 mm² / 4 m Ground cable with clamp

Reducer with flowmeter and 1 manometer

DFX5 – Dust Filter for MATRIX X 400 / X 500

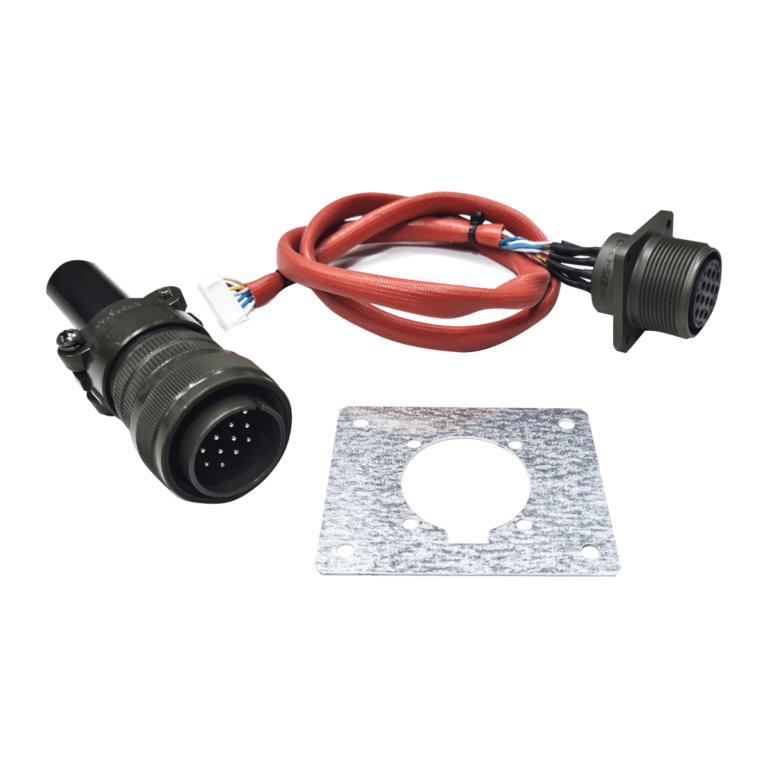

Adapter for simultaneous connection of Torch and PSR 7

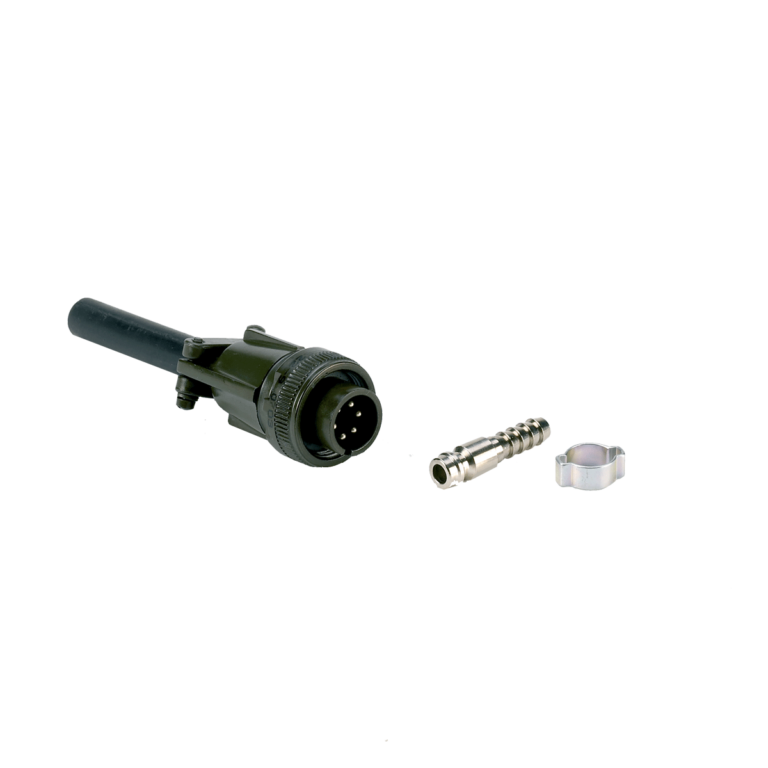

A6 Connection kit for non-standard Torch