SHARK 125

PLASMA CUTTING 120 A

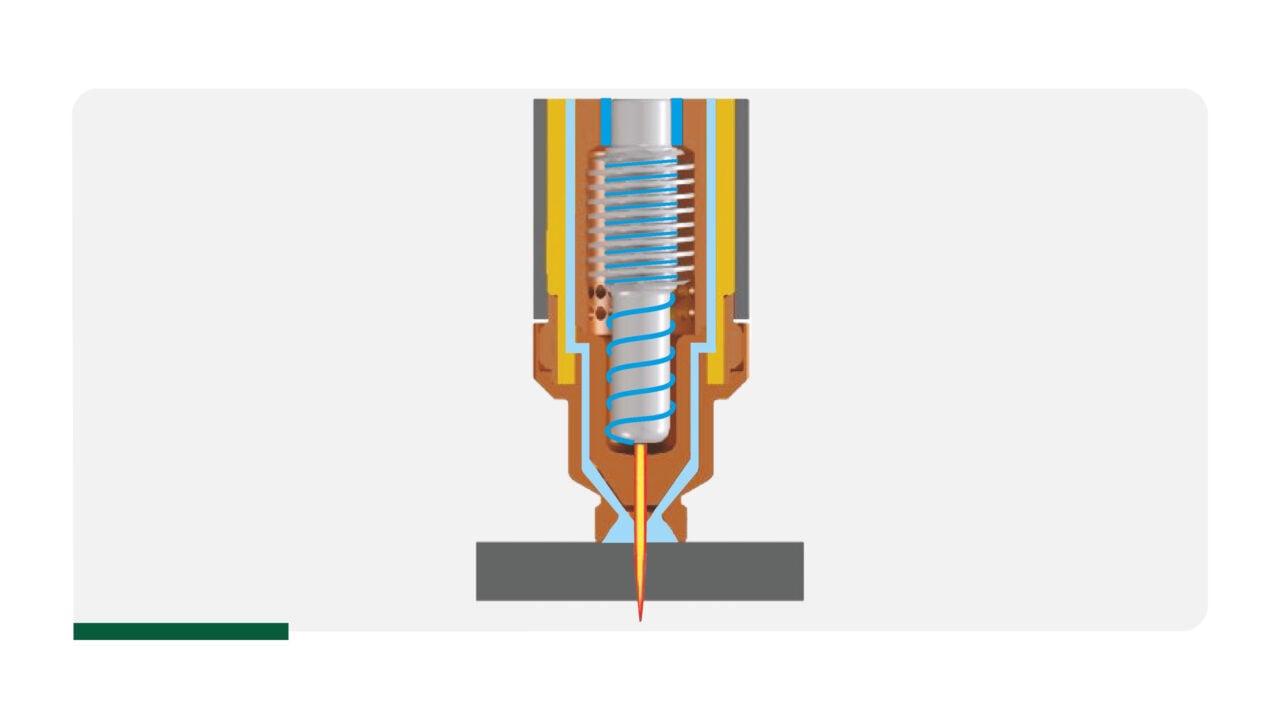

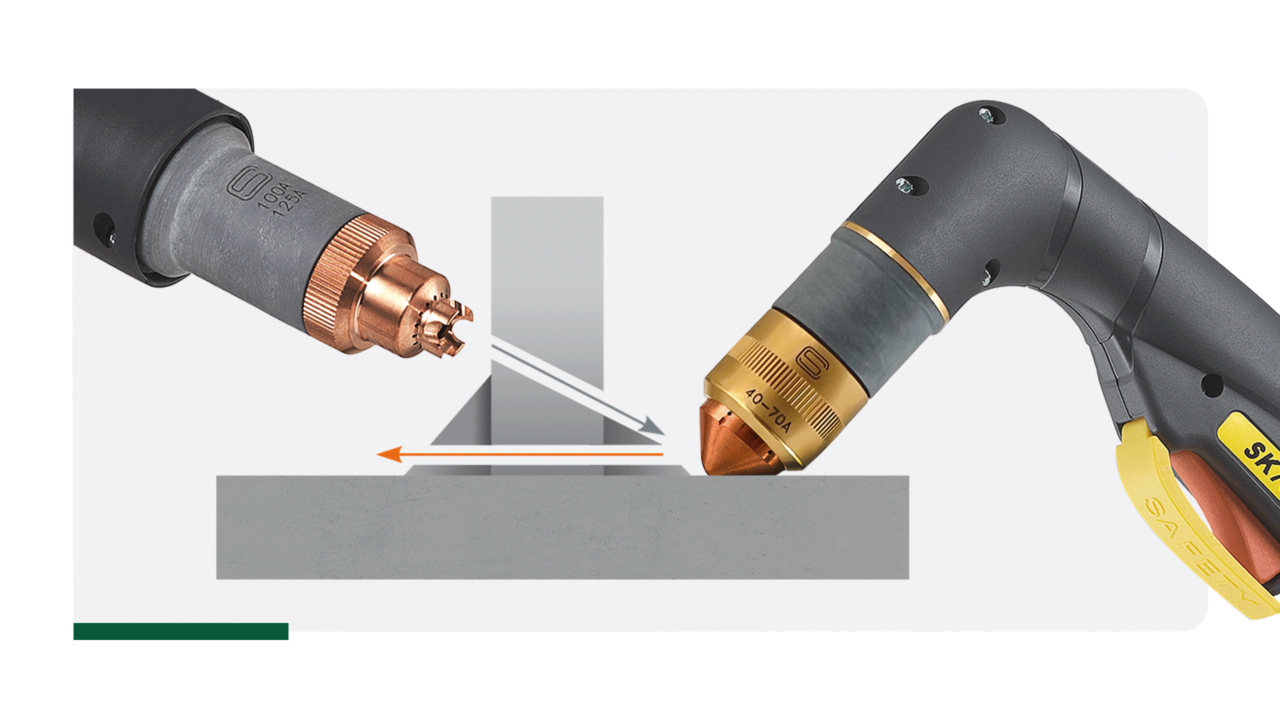

SHARK 125, in combination with the technology HPC of the torch SK125, it grants a cutting beam very concentrated

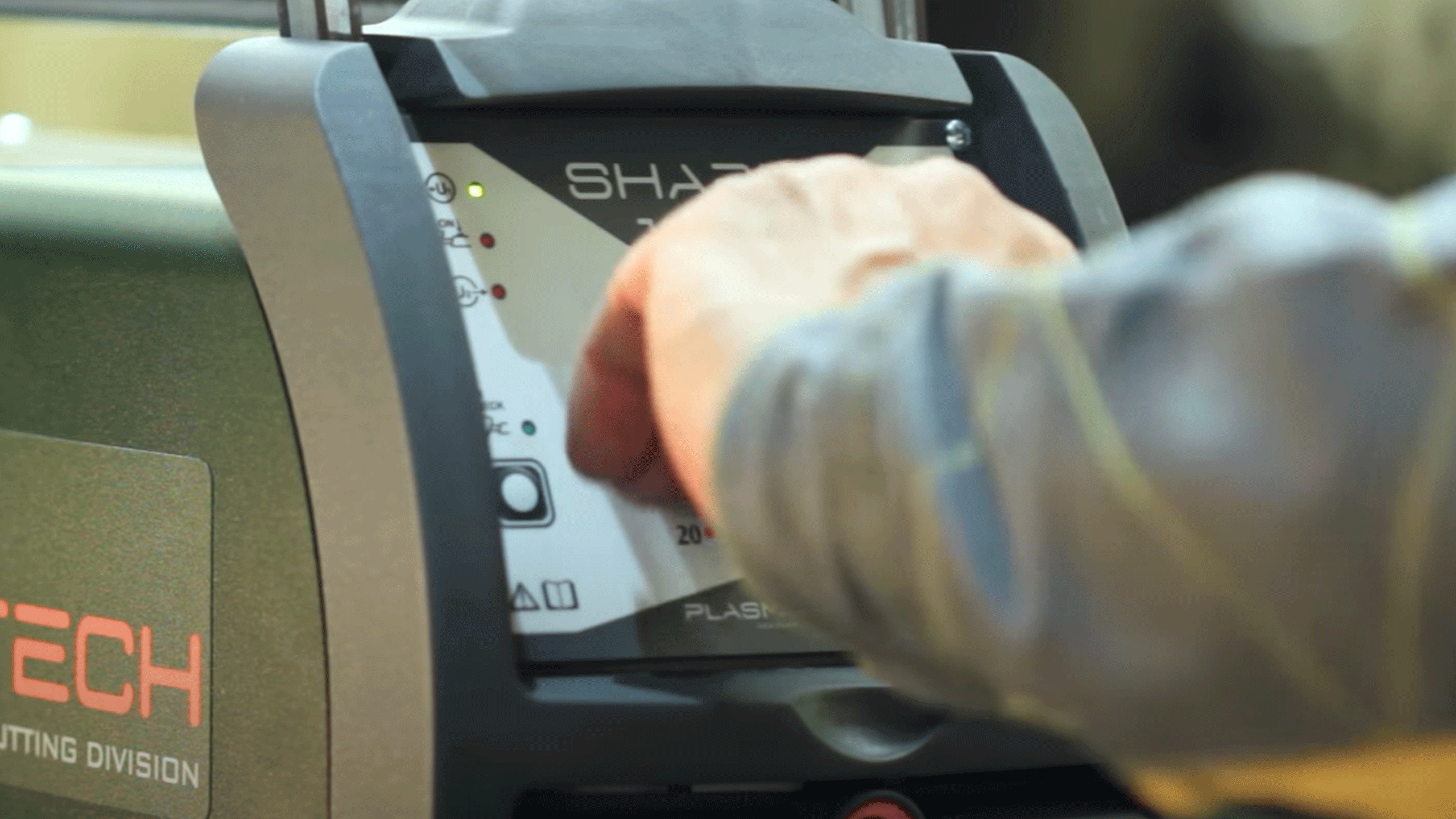

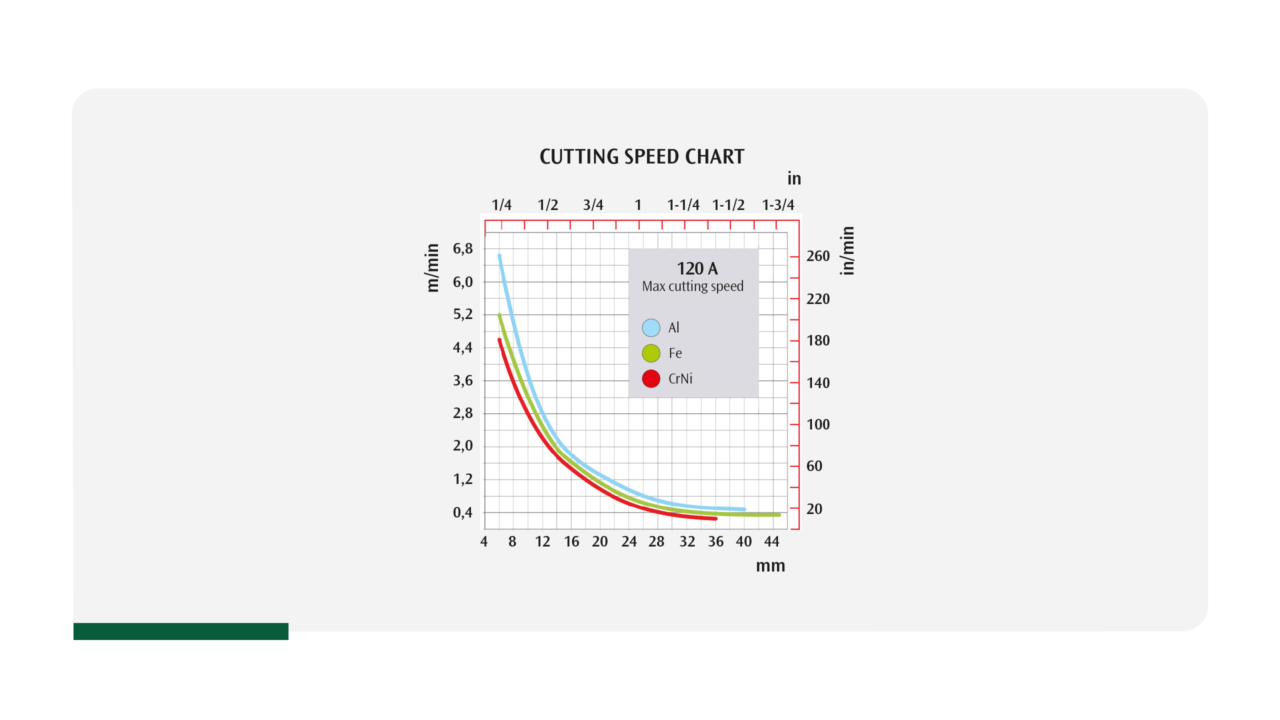

SHARK 125 is equipped with display for managing all the digital control. In combination with the technology HPC High-Performance-Cutting of the torch SK125, it grants to every user a cutting beam very concentrated and hot. This feature allows a very high precision and speed in cutting for a wide range of thickness. Shark 125 has also the special function Smart Start Transfer and Smart End Cutting for a better management of the cut during the start and end.

Main benefits

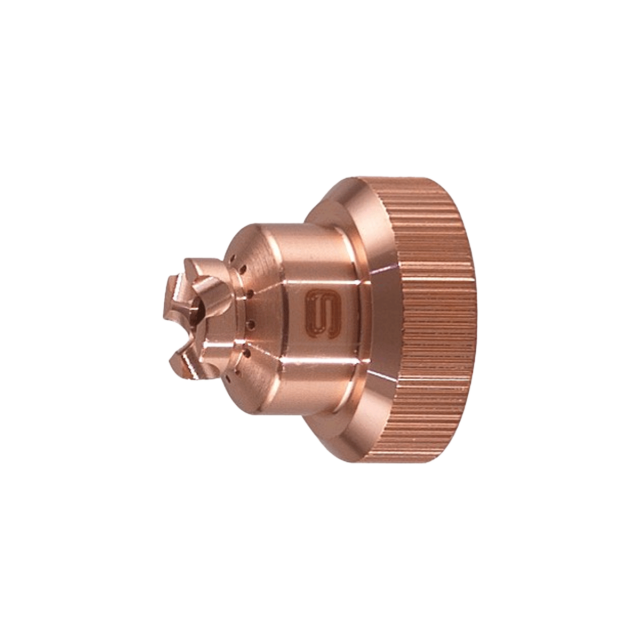

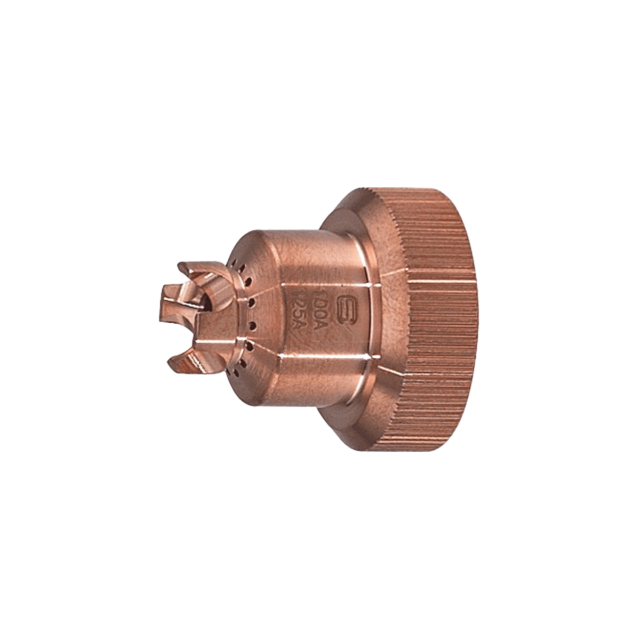

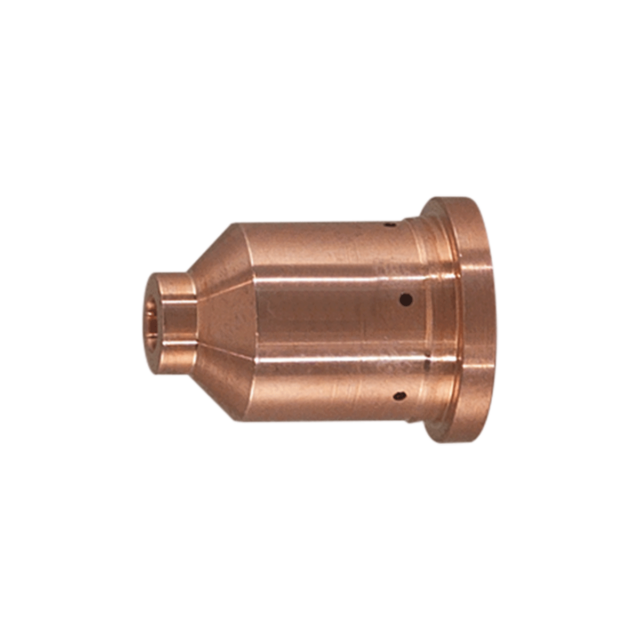

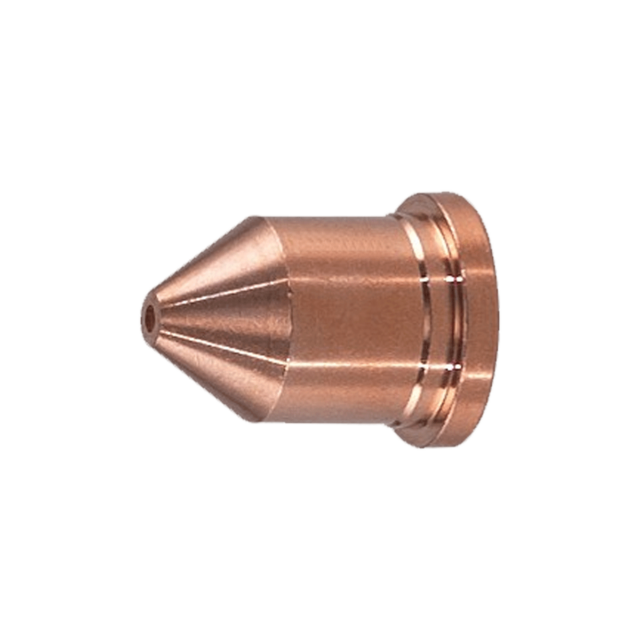

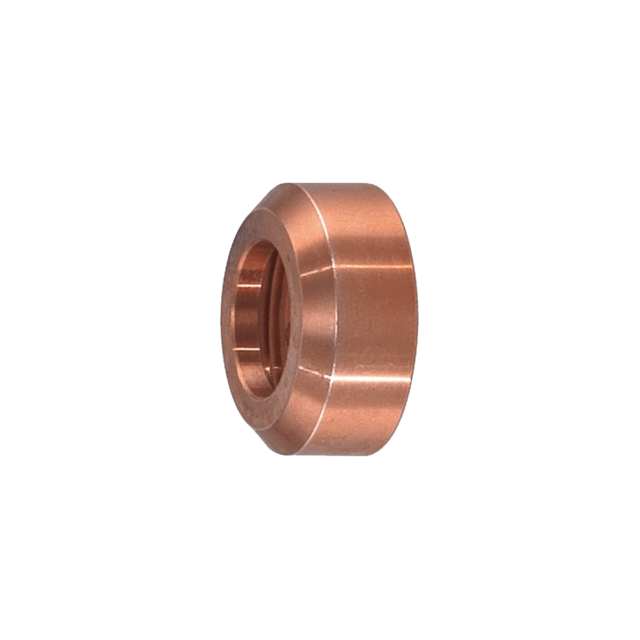

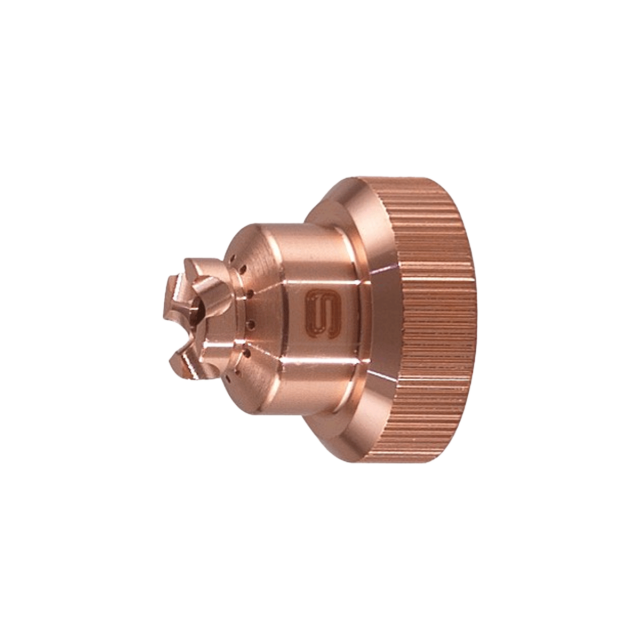

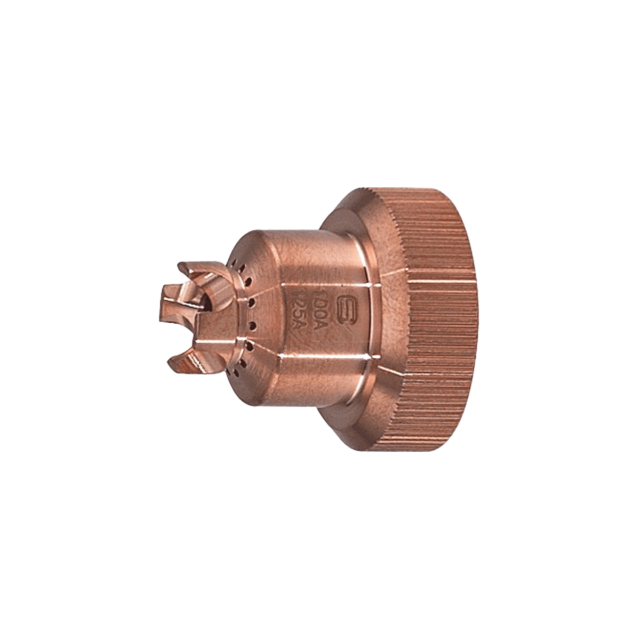

- SK125 torch with HPC High Performance Cutting technology and coaxial cable

- Digital display for the digital control of all parameters

- High duty cycle: 120A @ 60%

- More productivity thanks to high quality and cutting speed

Other characteristics

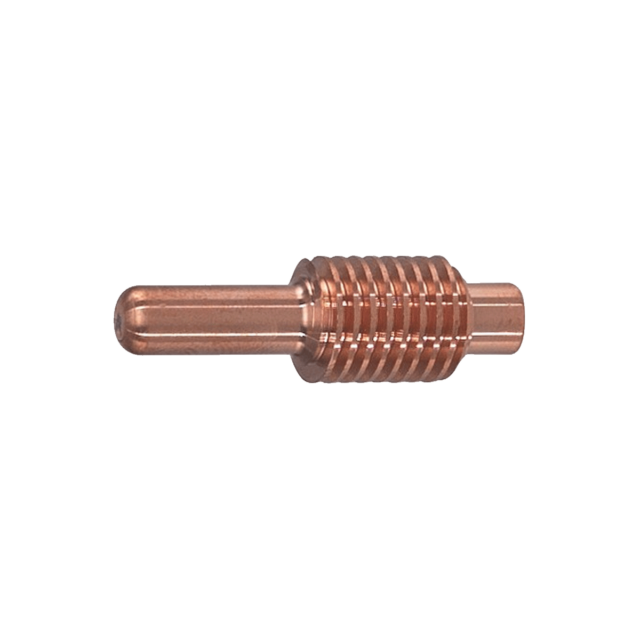

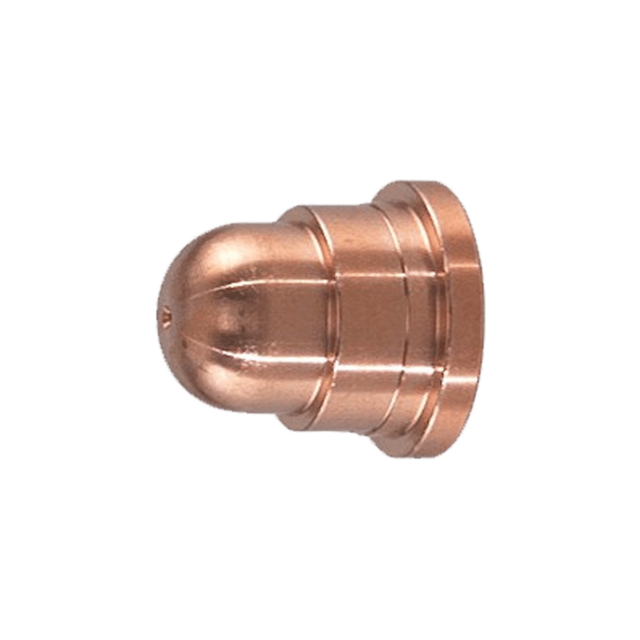

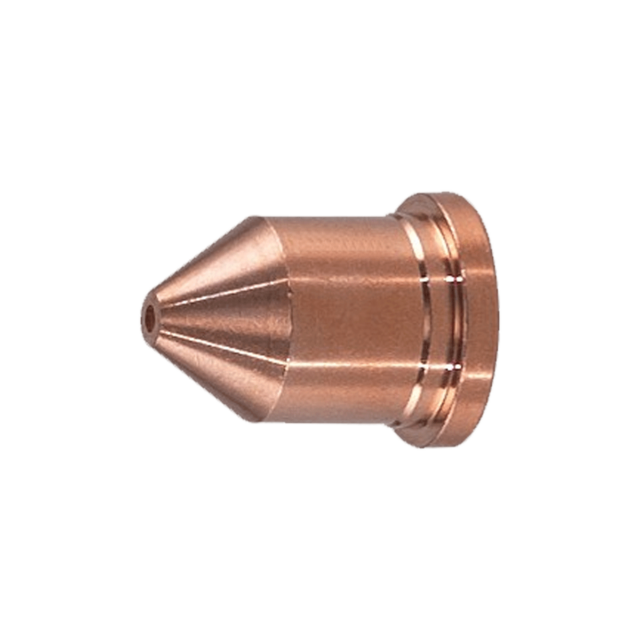

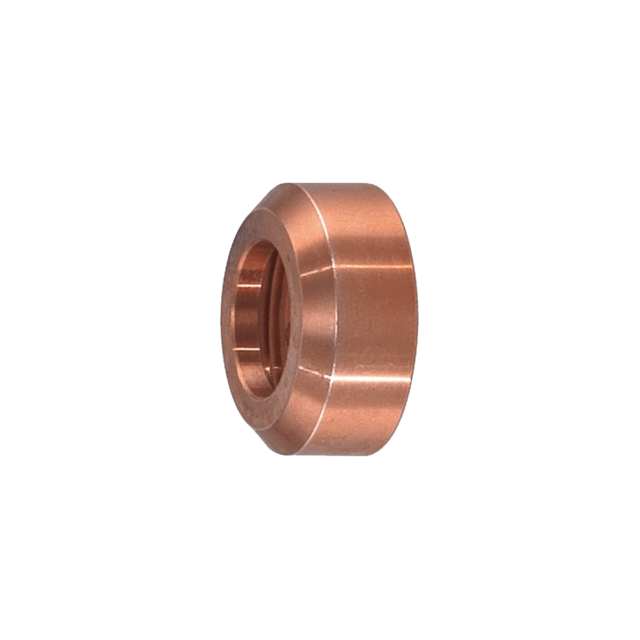

- Reduced operating costs granted by longer life of the consumable parts

- Electronic control for an excellent cutting quality

- Professional high flow air circulation

- Pilot arc torch

- Possibility of cutting grids and perforated lamination sheets

- Contact cutting possibility

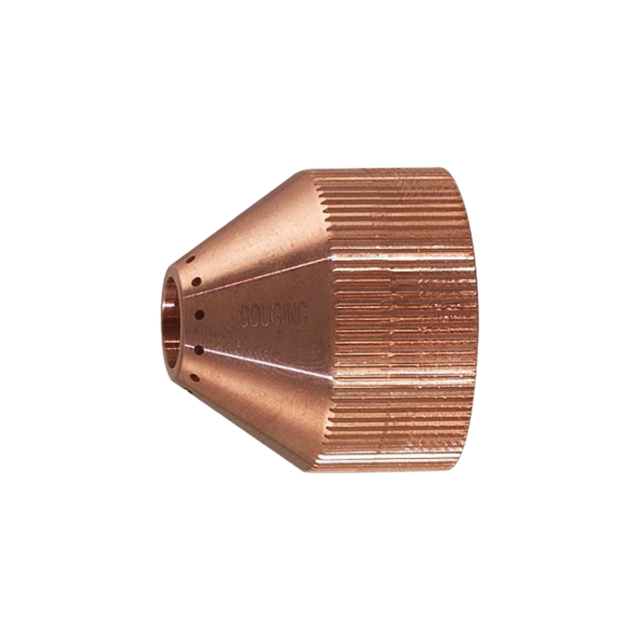

- Ability to gouging jobs

- Cutting parameter stability within ±20% mains voltage fluctuations

- Shockproof and dustproof control rack protection cover

- Electric protection on the torch for the maximum safety of the operator

Technical features

Available accessories

Discover all available accessories

Manual Long Torch SK 165xl 1,30m/45° – 7,5m cable 160A

Discover more on HERE

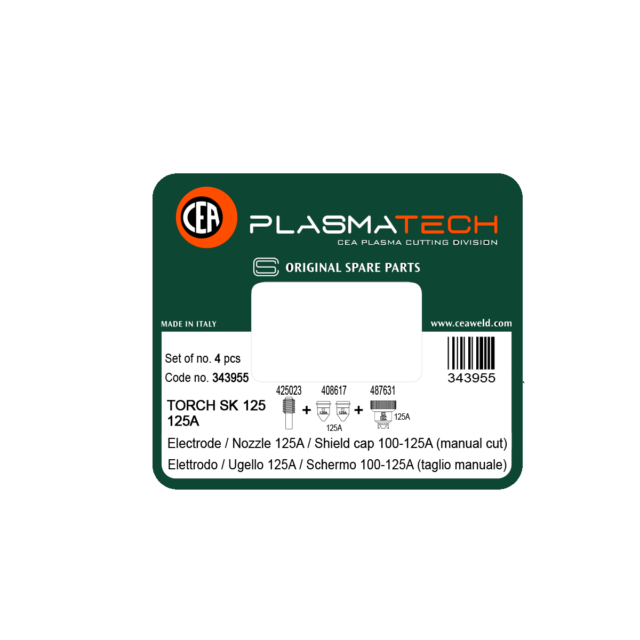

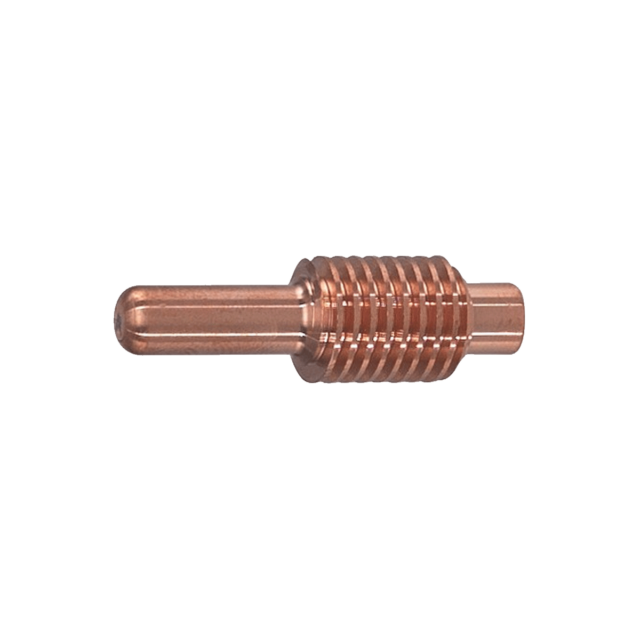

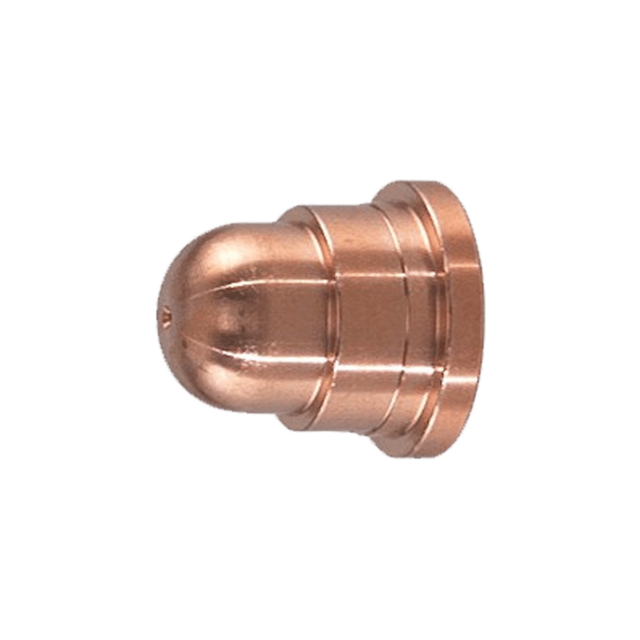

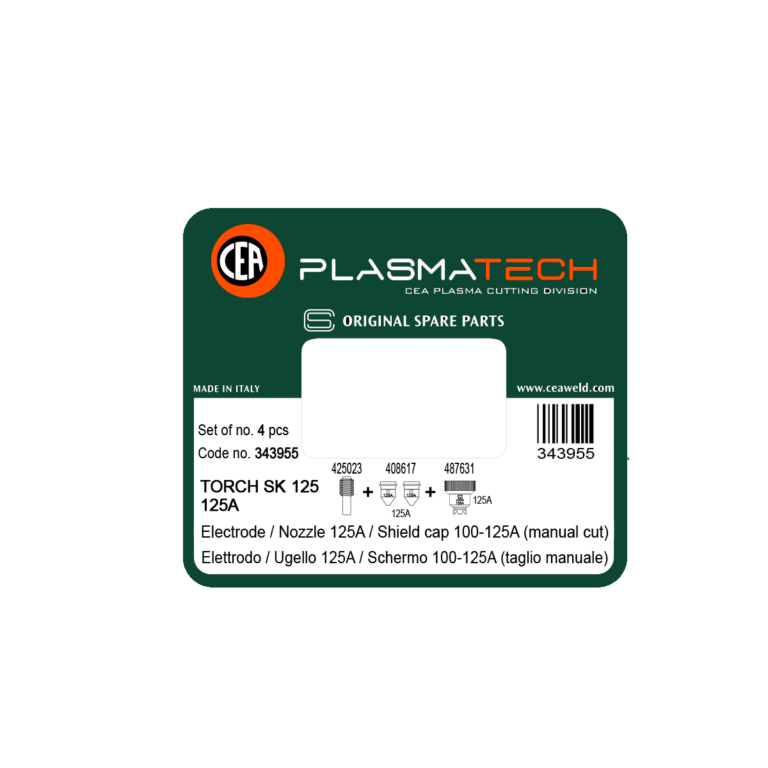

Consumable Starting Kit for SK 125: 1Electrode, 2 Nozzle 125A , 1 Shield cap 100-125A

Compass for SK 75 torch

Wheeled torch holder

Bevel Tool Kit: guide carriage and circle attachment for straight and bevel cutting.

Transport Trolley CTP 15

Compressed air filter

Filter cartridges package of 4 pcs

Gallery

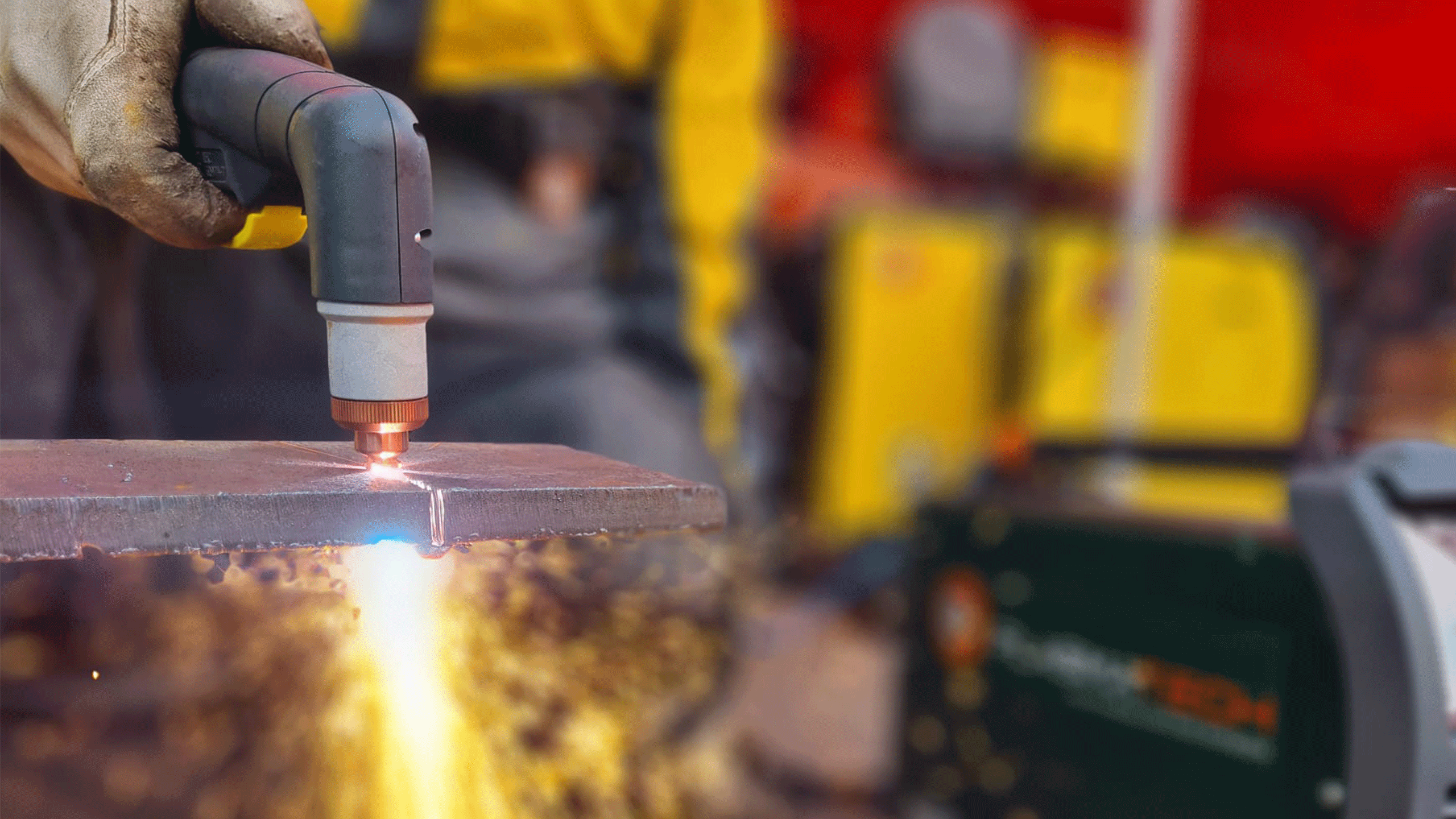

SHARK 125 at work

Datasheet

SHARK 125: Technical features

| TECHNICAL DATA | SHARK 125 |

||

| Input Voltage 50/60 Hz | V |

400-3ph

|

|

| Input Power @ I2 max | kVA | 21 | |

| Delayed Fuse (I2 @ 100%) | A | 32 | |

| Power Factor / cos φ | 0,89/0,99 | ||

| Efficiency Degree | % | 88 | |

| Current range | A | 25 ÷ 120 | |

| Duty Cycle (40°C) | 100% | A | 100 |

| 60% | A | 120 | |

| 30% | A | – | |

| Motorgenerator requirement for full capacity | kVA | 40 | |

| Cutting Capacity | Recommended | mm | 40 |

| Maximum | mm | 45 | |

| Severance | mm | 50 | |

| Piercing | mm | 25 | |

| Gas supply | Aria / N2 | ||

| Gas Pressure | bar | 5,0 – 6,0 | |

| Gas Flow | l/min | 280 ÷ 330 | |

| Protection Class | IP | 23 S | |

| Dimension (LxWxH) | mm | 515 x 290 x 730 | |

| Weight | kg | 48 | |

Configurator

Configure SHARK 125 for your needs