Plasma cutting

SKM 125

Automated high quality torch

Automated torch 120 A

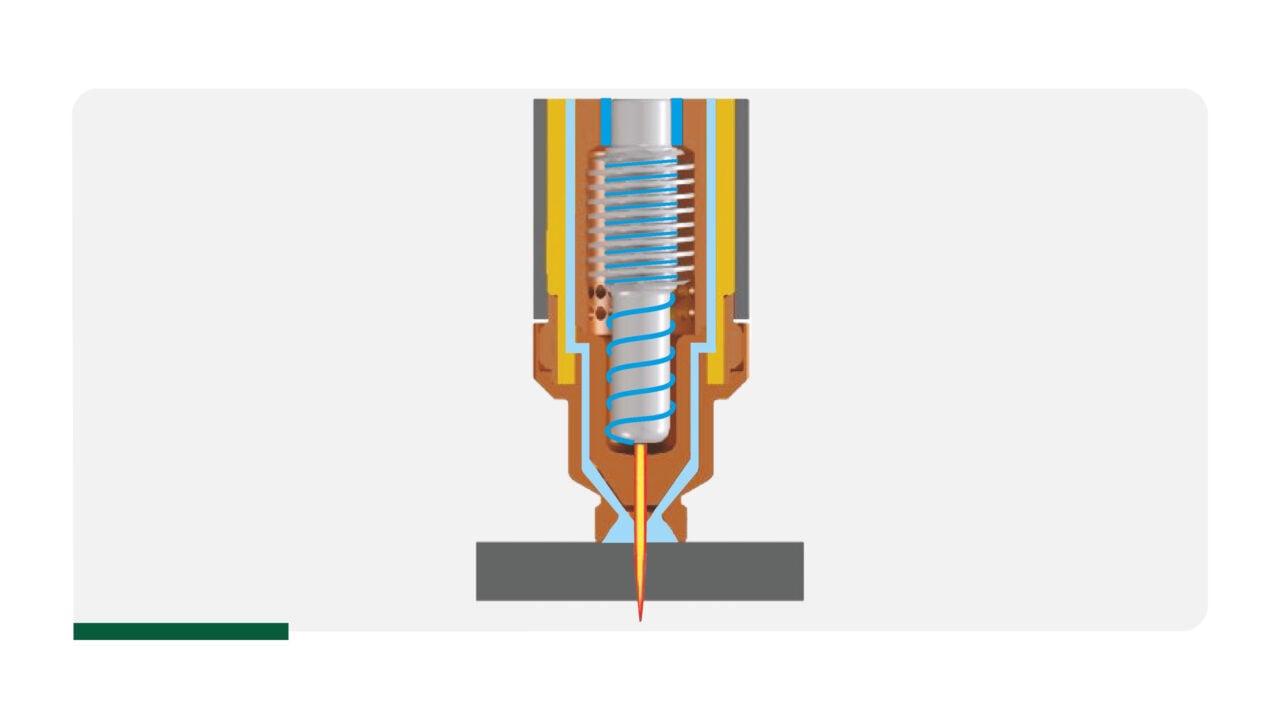

SKM125 torches for automated cutting are characterized by High Performance Cutting HPC technology which permits an increase in air quantity and speed, to better concentrate the plasma cutting beam and to stabilize the cutting arc.

Main features

- high cutting speed

- optimal quality and cleanliness of the cut surfaces

- high concentration of the plasma cutting beam

- lack of dross

- reduction in the heat affected zone

- longer life of the consumables

- piercing on lamination achieved in shorter times

- All SKM torches are fitted with a coaxial cable which combines great flexibility to robustness and resistance to crushing.

Technical features

Datasheet

SKM 125: Technical features

| POS. | CODE | DESCRIPTION | BLISTER QTY. |

| 1 | 422677 | Torch body | 1 |

| 2 | 433608 | O-ring | 20 |

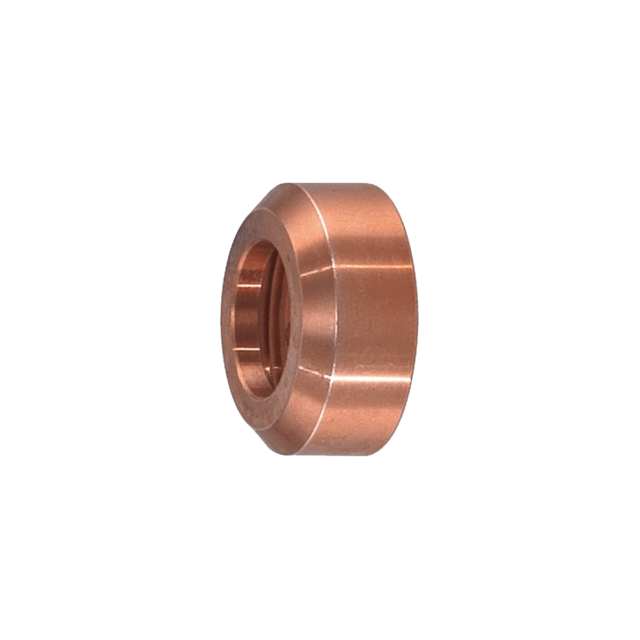

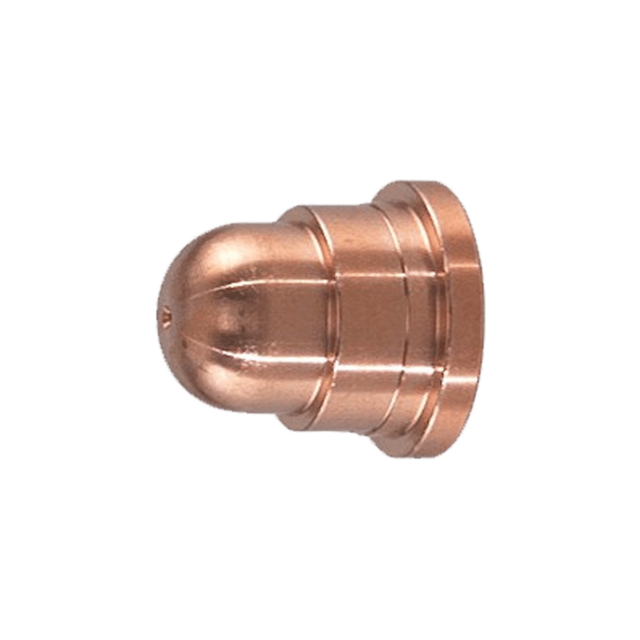

| 3 | 482135 | Swirl ring 45-85 A | 2 |

| 4 | 482136 | Swirl ring 100-125 A | 2 |

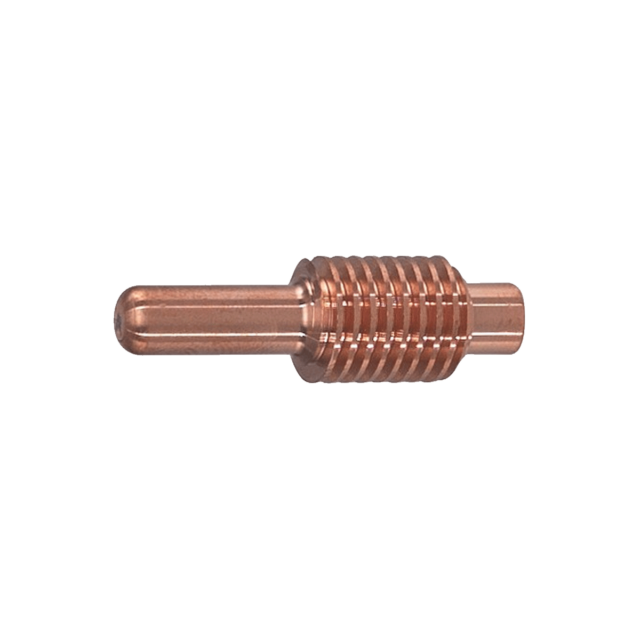

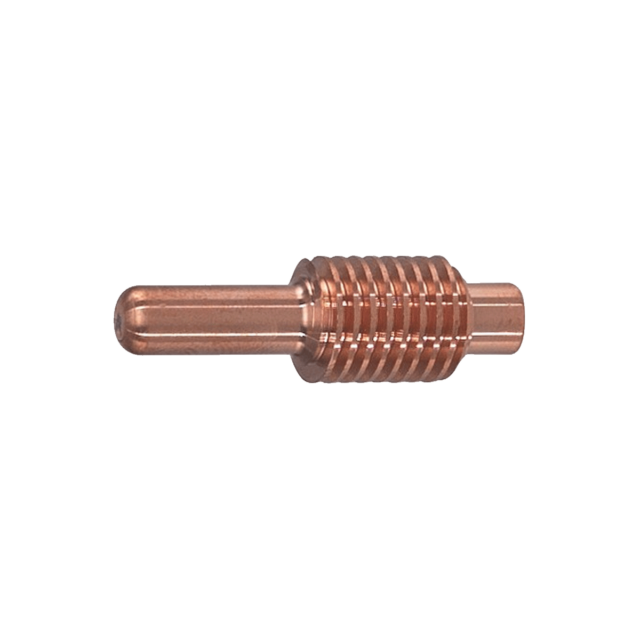

| 5 | 425023 | Electrode | 5 |

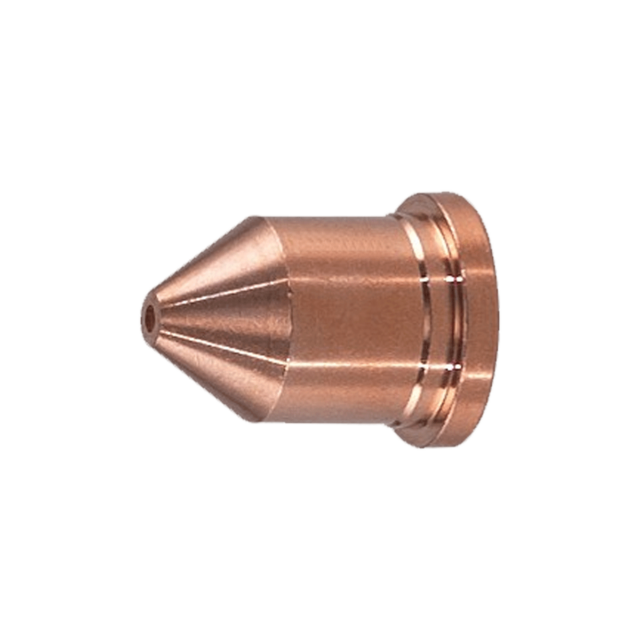

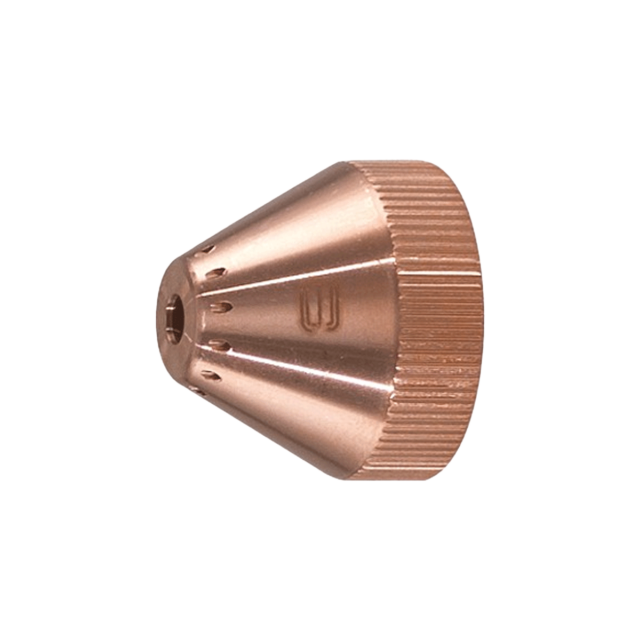

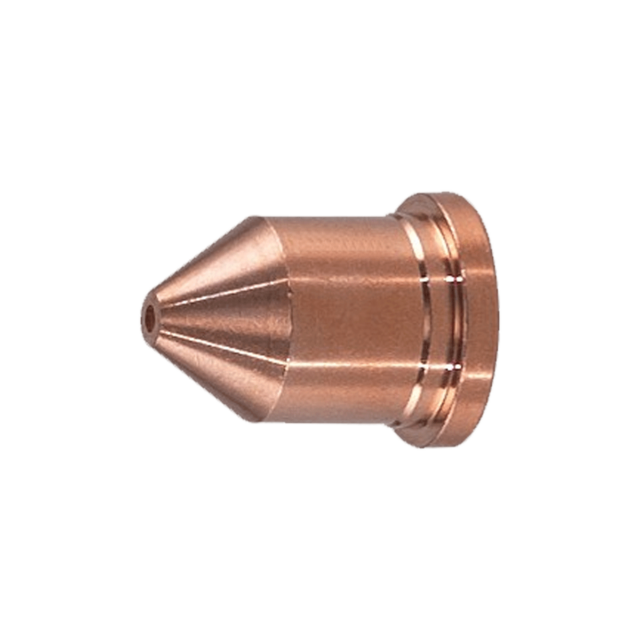

| 6 | 408613 | Nozzle 45 A, Clean-Cut | 10 |

| 7 | 408614 | Nozzle 45 A | 10 |

| 8 | 408615 | Nozzle 65 A | 10 |

| 9 | 408616 | Nozzle 85 A | 10 |

| 10 | 408612 | Nozzle 105 A | 10 |

| 10A |

408617 |

Nozzle 125 A | 10 |

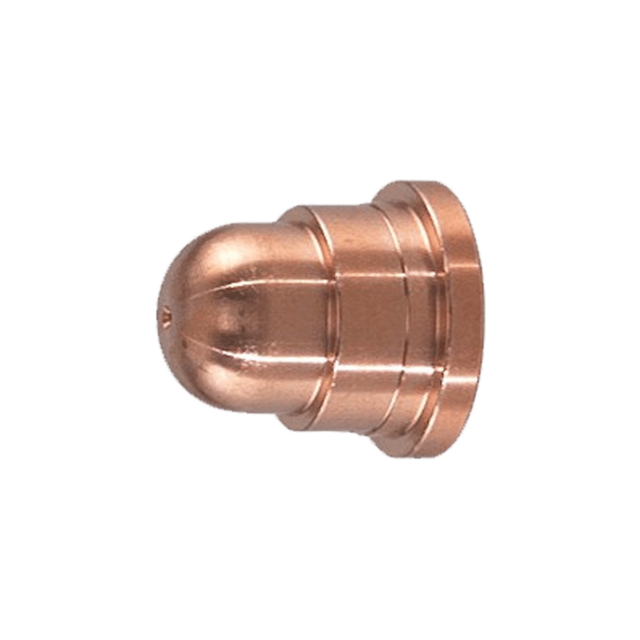

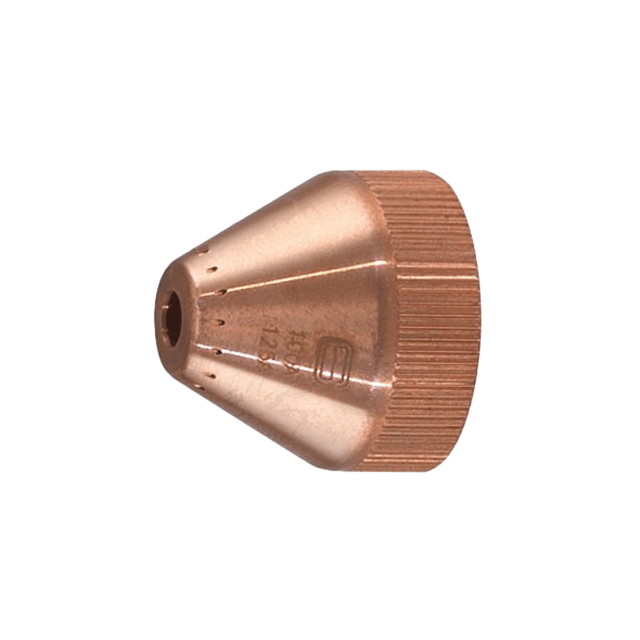

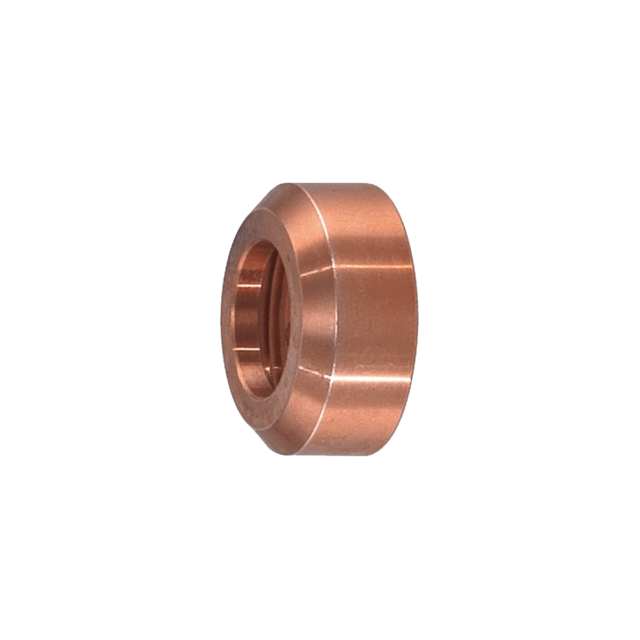

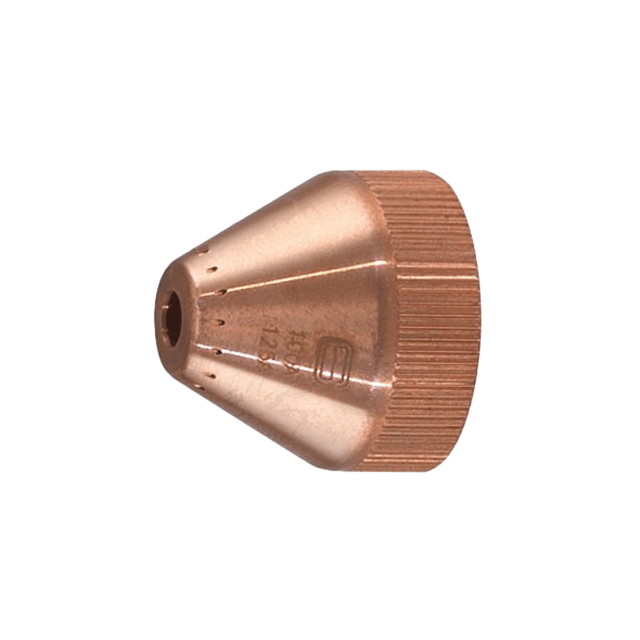

| 11 | 486028 | External nozzle 45-85 A | 1 |

| 12 | 486025 | External nozzle 45-85 A with ohmic sensor | 1 |

| 13 | 486029 | External nozzle 100-125 A | 1 |

| 14 | 486026 | External nozzle 100-125 A with ohmic sensor | 1 |

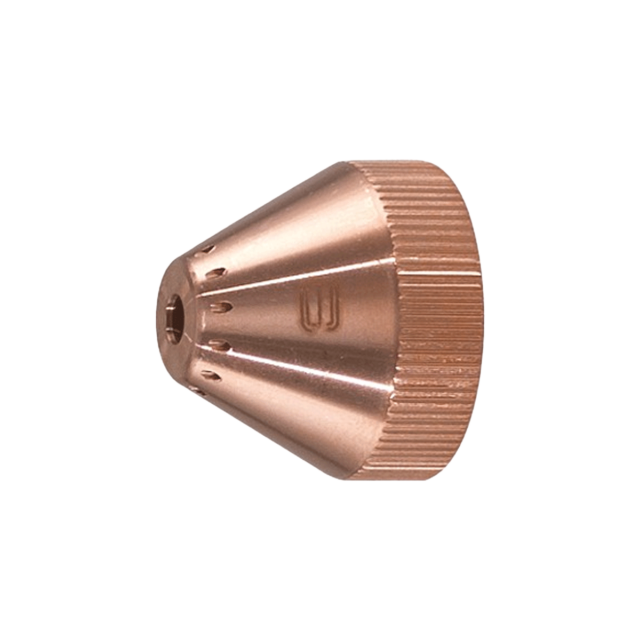

| 15 | 482030 | Shield cap 45 A – Clean-Cut | 3 |

| 16 | 487635 | Shield cap 45-85 A (mechanized cutting) | 2 |

| 17 | 487636 | Shield cap 100-125 A (mechanized cutting) | 2 |

Configurator

Configure SKM 125 for your needs

Select product

Select product

Consumables (multiple choice available)

Consumables

Swirl ring 45-85 A 2pcs

Consumables

Swirl ring 100-125 A 2pcs

Consumables

Electrode 5pcs

Consumables

Nozzle 45 A Clean-Cut 10pcs

Consumables

Nozzle 45 A 10pcs

Consumables

Nozzle 65 A 10pcs

Consumables

Nozzle 85 A 10pcs

Consumables

Nozzle 105 A 10pcs

Consumables

Nozzle 125 A 10pcs

Consumables

External nozzle 45-85 A 1pc

Consumables

External nozzle 45-85 A ohmic sensor 1pc

Consumables

External nozzle 100-125 A 1pc

Consumables

External nozzle 100-125 A ohmic sensor 1pc

Consumables

Shield cap 45 A - Clean-Cut 3pcs

Consumables

Shield cap 45-85 A 2pcs

Consumables

Shield cap 100-125 A 2pcs

Capsules (multiple choice available)

Capsules

Capsule machine cut 65 A 1pcs

Capsules

Capsule machine cut 85 A 1pcs

Capsules

Capsule machine cut 105 A 1pcs

Capsules

Capsule machine cut 125 A 1pcs

Select product

Consumables (multiple choice available)

Consumables

O-ring 20pcs

Consumables

Swirl ring 45-85 A 2pcs

Consumables

Swirl ring 100-125 A 2pcs

Consumables

Electrode 5pcs

Consumables

Nozzle 45 A Clean-Cut 10pcs

Consumables

Nozzle 45 A 10pcs

Consumables

Nozzle 65 A 10pcs

Consumables

Nozzle 85 A 10pcs

Consumables

Nozzle 105 A 10pcs

Consumables

Nozzle 125 A 10pcs

Consumables

External nozzle 45-85 A 1pc

Consumables

External nozzle 45-85 A ohmic sensor 1pc

Consumables

External nozzle 100-125 A 1pc

Consumables

External nozzle 100-125 A ohmic sensor 1pc

Consumables

Shield cap 45 A - Clean-Cut 3pcs

Consumables

Shield cap 45-85 A 2pcs

Consumables

Shield cap 100-125 A 2pcs

Capsules (multiple choice available)

Capsules

Capsule machine cut 65 A 1pcs

Capsules

Capsule machine cut 85 A 1pcs

Capsules

Capsule machine cut 105 A 1pcs

Capsules

Capsule machine cut 125 A 1pcs