Industry 4.0 applications: Digitech VP2, Inverter welding machine by CEA

The guidelines dictated by industry 4.0 highlight, as we stated in previous articles, the importance of having synergic systems in companies’ production lines.

Synergic machines are those that, through specially designed interfaces, work with the operator to optimise the quality of the work and increase productivity.

CEA has designed the line of synergic pulsed multiprocess inverter generators Digitech VP2 precisely to meet the needs of companies with an eye on progress following the idea of the smart factory.

If you want a FREE DEMO of our products or need some information click here! We're at your service!

Industry 4.0 applications in Inverter welding machine: Controlled welding processes

In the Digitech VP2 line (3300, 4000 and 5000) there is a digital control system, called vision.ARC2, that can best handle the welding process.

The welding machine microprocessor guides the operator in choosing the ideal parameters for different types of materials to weld, assessing the diameter of the wire and the gas used.

Vision.ARC2 can control arc stability and actively operate in pulsed welding, correcting the pulse if necessary.

The settings for MIG welding are handled by the software designed by CEA for a constant arc and optimal droplet detachment.

Therefore, we can summarise the main advantages of vision.ARC2 with:

- improved arc stability

- optimised pulse characteristics

- quick and accurate control of short-circuits in case of welding with a very short arc

- increased welding speed

- added reduction of heat input

Read also: " Quality welding machine: Why opt for CEA "

Additionally, this advanced system can control the special welding processes designed by CEA to facilitate special works:

- vision.PIPE: Thanks to the low heat input, it enables welding with the torch in all positions without creating drips. Indeed, this is an innovative MIG/MAG process developed by CEA for welding the initial root pass at the butt-joint of pipes in all positions, covering even significant gaps. The vision.PIPE process enables replacing TIG and MMA processes with a significant increase in welding performance speed.

- vision.COLD is an innovative MIG/MAG process, with a low heat input, developed by CEA for welding thin sections and for MIG brazing in all welding positions. It also makes it easier to weld with the vertical-down method

- vision.ULTRASPEED is the innovative MIG/MAG process developed by CEA for welding steels and non-ferrous materials that, thanks to the increase in the arc’s magnetic force and a more restricted arc cone, enables a marked increase in welding speed. This process ensures less overheating of the base metal with lower shrinkage stresses and subsequent reduction in reworking the finish. The vision.ULTRASPEED process enables replacing short-arc mix-arc welding in MIG/MAG with a significant increase in welding performance speed.

- vision.POWER is the innovative MIG/MAG process developed by CEA for welding medium and thick section steels where high penetration is required. Using this special welding process, the arc cone is narrower, and thus its pressure is focused on a smaller surface of the base metal, significantly increasing penetration. The highly concentrated arc of the vision.POWER is also ideal for corner welding and in restricted openings with a high stick-out length. The vision.POWER process enables replacing spray-arc welding in MIG/MAG with a significant increase in both penetration and welding performance speed.

- vision.PULSE-UP was specifically designed for vertical-up welds. Vertical welding is the process where the human element is most important, as it is traditionally done with a complex manual motion called a “Christmas tree” pattern. The special process created by CEA avoids using this method, enabling welding with a simple linear motion that can also be done by an unskilled welder. In using the special vision.PULSE-UP process, the Pulsed MIG ensures the perfect melting of material with no spatter or short-circuits, while the MIG process, thanks to its low energy input, allows solidifying and shaping the deposited material. The end result is a narrower bead, well-sized and with no defects.

- vision.PULSE-POWER is designed to quickly achieve a well-flattened weld bead with high penetration. The cleaning obtained is closer to that of the purely pulse process. In using the special vision.PULSE-POWER process, the Pulsed MIG ensures the perfect melting of material with no spatter or short-circuits, while vision.POWER allows greater penetration and an increased weld speed along with lower energy input and easier control of the deposited material. The result is a well-flattened bead, well-penetrated and with no defects. Additionally, by using this process, the welder can proceed linearly, more easily, without the usual manipulation of the torch.

- vision.PULSE-RUN merges the features of Pulsed MIG and vision.ULTRASPEED; choose whether you prefer a cleaning closer to the purely pulse process, but at a markedly higher speed. In using the special vision.PULSE-RUN process, the Pulsed MIG ensures the perfect melting of material with no spatter or short-circuits, while entering vision.ULTRASPEED enables reducing the heat input and increase the welding speed.

Read also: " Robotic welding: 5 good reason to buy high-tech welding machine "

Inverter welding machine: Avoid the issues of MIG/MAG welding

In traditional MIG/MAG welding, the problem of spray transfer due to the high heat input is avoided thanks to the pulsed current.

The Digitech VP2 welding machines, thanks to vision.PULSE, control the arc length, decreasing the heat input and increasing both the speed, and quality of the welding.

When using Dual Pulse, welding deformations are further reduced, as the heat input decreases further with respect to traditional pulsed welding.

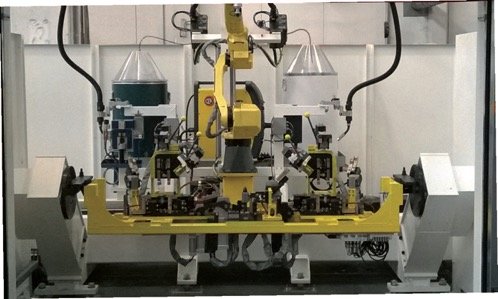

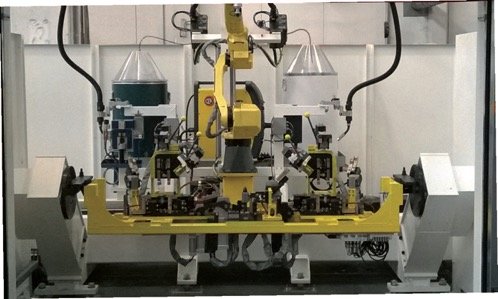

The benefits of robot welding with Digitech VP2

The pulsed inverter generators in this line of CEA products can be easily used in robot welding systems, obtaining greater efficiency, just as indicated in the guidelines of industry 4.0.

Thanks to the Robot CEA interface, it is possible for Digitech VP2 to communicate with the robots in the production line, fully automating the work process.

CEA systems are designed to be constantly updated, thus following technological developments without replacing complete machinery.

{{cta('c9819577-65d8-4853-80d0-e1a00c4511b7','justifycenter')}}