TIG welding machines. The line of CEA auto welders: TIG automation

CEA’s lengthy experience in the field of welding has enabled the company to create product lines designed to assist those who work with these tools every day.

The professionals who use CEA welding systems are satisfied with an advanced technology that has helped carry out even complex work. Those who are beginners can appreciate the ease in which arc welding machines can be used optimally.

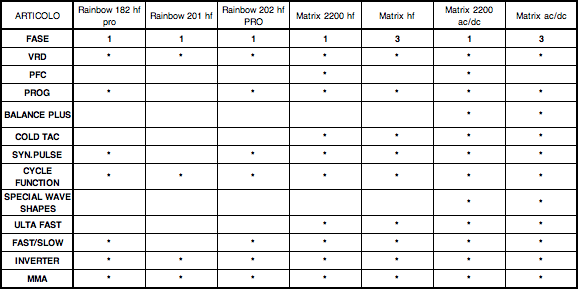

The product catalogue features the following TIG welding machine lines:

- TIG DC

- TIG AC-DC

- TIG - Automation

In this article we will talk about TIG - Automation.

Read also the first part of the article: "TIG welding machine: DC and AC DC welding machine designed by CEA"

CEA auto welders machines

The CEA Robotics – Automation team has created arc welding machines suitable for automatic systems and auto welders.

For TIG welding, the ROBOMAT 1 interface system was designed, which is applied to MATRIX HF-R and MATRIX AC/DC-R models, and meets all the Analogue/Digital connection requirements.

This interface guides the work of three-phase welding machines, managing their settings and start-stop signals.

Furthermore, CEA can design tailored solutions for particularly complex robotic production lines, or which have specific requirements.

If you want a FREE DEMO of our products or need some information click here! We're at your service!

Special functions for the TIG welding machines configuration

CEA’s TIG welders have innovative functions to assist operators in their work, ensuring high quality and a significant increase in efficiency.

The main functions designed for special work are:

- PFC (Power Factor Correction).

The PFC device makes the waveform of the absorbed current sinusoidal with a consequent absence of harmonic noise in the mains and optimisation of the absorption that allows the use of the full power of the generator with 16 A fuse. The PFC circuit ensures greater protection of the welding machine against fluctuations in the supply voltage, making it even safer when used with motor-generators.

The PFC device makes the waveform of the absorbed current sinusoidal with a consequent absence of harmonic noise in the mains and optimisation of the absorption that allows the use of the full power of the generator with 16 A fuse. The PFC circuit ensures greater protection of the welding machine against fluctuations in the supply voltage, making it even safer when used with motor-generators.

- VRD (Voltage Reduction Device), an important safety element in case of work in damp locations and with an increased risk of electric shock. . The VRD lowers the unloaded voltage to values under 12 V, ensuring the use of the welding machine in environments with a high electrical risk, thus offering maximum safety to the operator.

- Storage of multiple work programs to optimise time

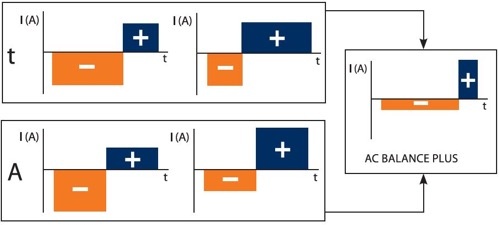

- Balance Plus (a function to join metal surfaces of differing thickness). Possibility of independently adjusting the time and width of the current, guaranteeing perfect control of penetration and cleaning, with a drastic reduction of side undercuts. An additional advantage of Balance Plus is the significant reduction in electrode wear.

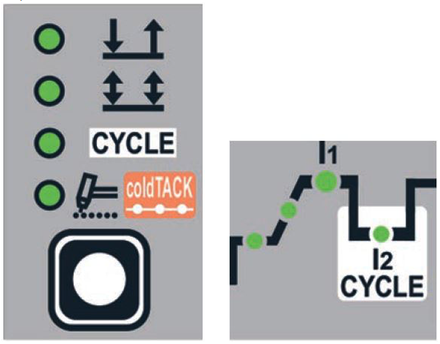

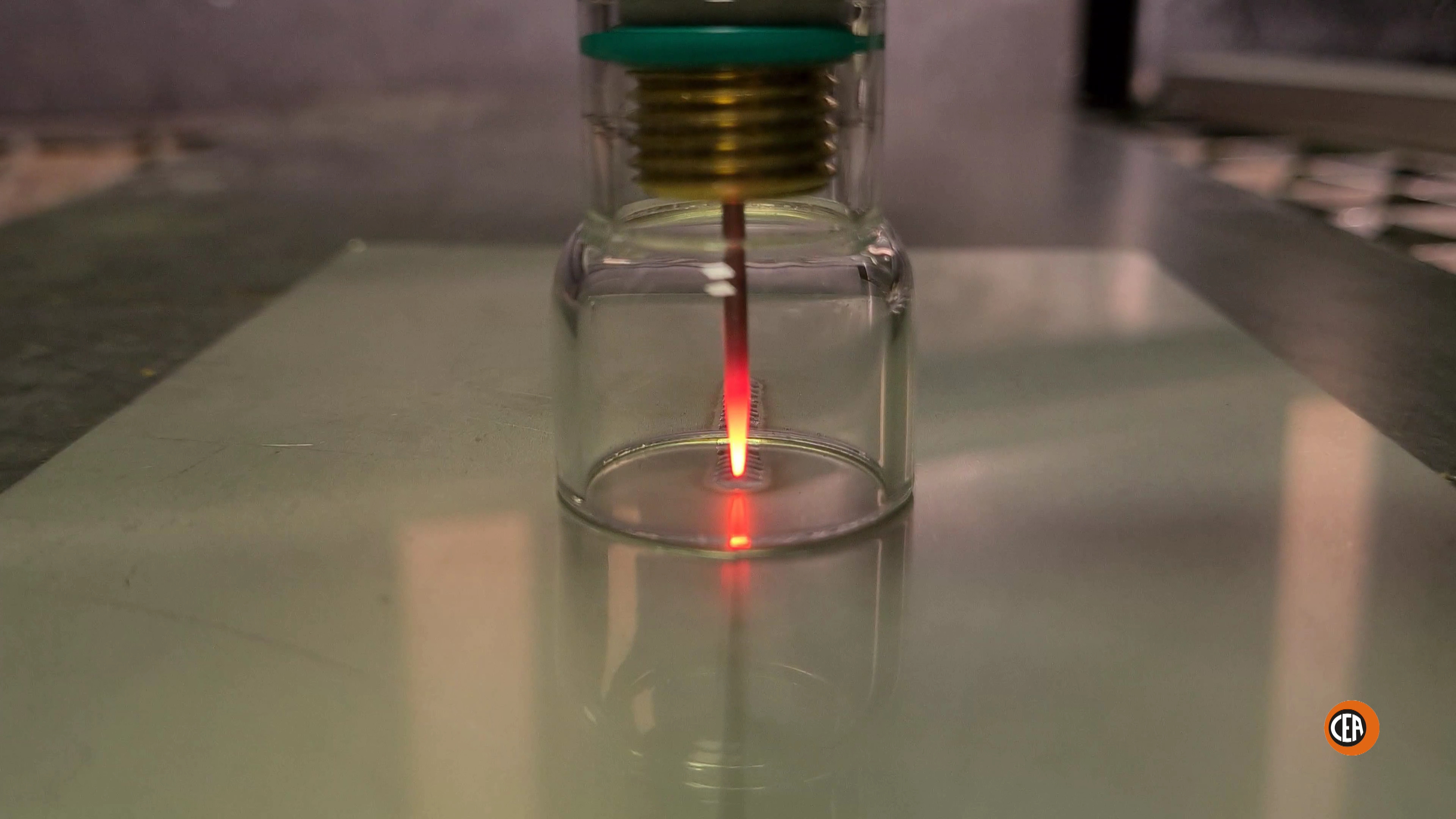

- Cold Tack (to make precise, cold and uniform weld tacks in TIG); thanks to CEA’s experience in software development, it has been possible to create the Cold Tac function. This process enables creating precise, cold and uniform weld tacks in TIG, eliminating human know-how from the process. This ensures the creation of work of the highest aesthetic quality, ensuring invisible weld points after the second, final joint welding.

READ ALSO: "Robotic welding: 5 good reasons to buy high-tech welding machines"

- TIG RCT is a new welding process, now available on all the Matrix range, which allows to weld in TIG to realize very cold welding seams. RCT is the acronyms of RUNNING COLD TACK; indeed the TIG RCT process allows to benefit of all the coldTACK advantages, by repeating the single coldTACK point in a continuous way, in order to achieve a cold and perfect welding seam. Using TIG RCT the welding seam is much colder in comparison to the one achievable with Pulse TIG and it represents the ideal solution to weld thin materials with a very low heat transfer. TIG RCT is a direct current process not available in AC welding.

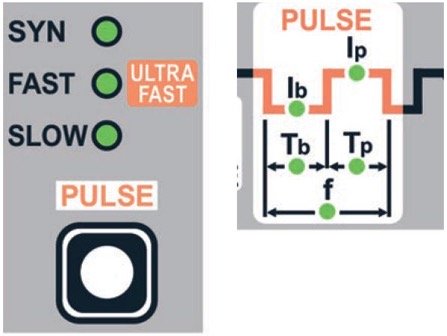

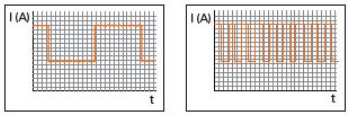

- SYN.Pulse. Syn Function (function that automatically manages the pulse frequency and base current). Setting times are decreased while unskilled operators are assisted.

- Cycle Function (enables selecting two current values by pressing the button on the torch). Designed for welding on different thicknesses where the current needs to be changed

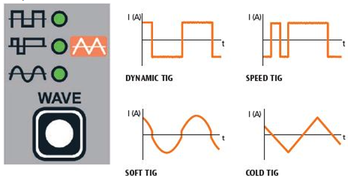

- Special Wave Shapes (selects different waveforms in AC)

- DYNAMIC TIG, SOFT TIG, SPEED TIG, COLD TIG

- Ultra Fast (better arc control and lower deformation of the material). Useful for welding thin sheet metal and to have an increase in penetration when working quickly.

- Slow (separate setting of peak and base current times). Achieves excellent fill and good finish

Thanks to our experience, our company can offer solutions to all the problems that can be encountered in welding.

{{cta('c9819577-65d8-4853-80d0-e1a00c4511b7','justifycenter')}}

The PFC device makes the waveform of the absorbed current sinusoidal with a consequent absence of harmonic noise in the mains and optimisation of the absorption that allows the use of the full power of the generator with 16 A fuse. The PFC circuit ensures greater protection of the welding machine against fluctuations in the supply voltage, making it even safer when used with motor-generators.

The PFC device makes the waveform of the absorbed current sinusoidal with a consequent absence of harmonic noise in the mains and optimisation of the absorption that allows the use of the full power of the generator with 16 A fuse. The PFC circuit ensures greater protection of the welding machine against fluctuations in the supply voltage, making it even safer when used with motor-generators.