Shark: Plasma cutting machine designed by CEA

Over the years, CEA has invested much into the study and creation of inverter generators for plasma cutting; indeed, at the company, there is a department fully dedicated to these products, called Plasmatech.

The know-how gained over thirty years on the market, allows us to meet all the requirements of customers who need effective and reliable tools for cutting metal.

If you want a FREE DEMO of our products or need some information click here! We're at your service!

Shark by CEA, the machine for plasma cutting any metal

In factories that need to cut metals of various kinds, grids and perforated sheet metal, generators for plasma cutting that are precise and easy to use are essential for high quality work.

The Shark plasma cutting systems ensure precision through torches with specially made consumables, excellent electronic control and the flexibility provided by the inverters used throughout the range. CEA’s machines enable selecting the best parameters for the metal to be cut and its thickness.

Shark generators can be used for:

- Manual cutting with SK torch

- Automated CNC cutting with SKM torch

The new-design torches enable cutting any material without the high frequency required for igniting the arc.

Read also: " Robotic welding: 5 good reason to buy high-tech welding machines "

The models in the plasma cutting line are:

- SHARK 25

- SHARK 45

- SHARK 75

- SHARK 75 M*

- SHARK 105

- SHARK 105 M*

- SHARK 155

- SHARK 155 M*

- SHARK 155 MR*

*The letter M identifies the machines for automated plasma cutting, while R indicates those for robot cutting.

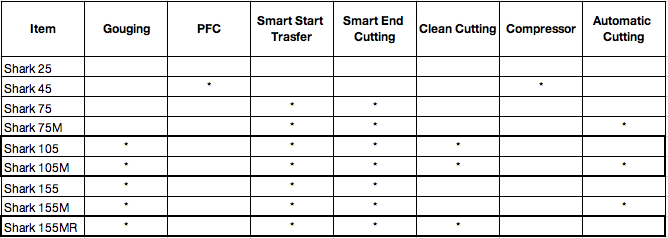

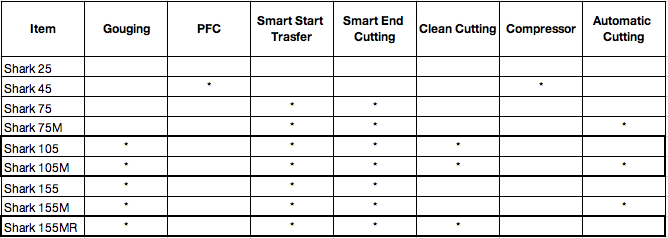

The comparative table below lists the main features for each model:

- Smart Start Transfer is the technology that enables transferring the pilot arc to main arc gradually, which entails a more stable plasma flow and longer life for the torch consumables.

- Smart End Cutting comes into play at the end of the cut, gradually decreasing the current and, therefore, ensuring the clean separation of the workpiece, without the operator having to do so manually.

- Scarfing using plasma (Gouging), which can be done using the Shark models shown in the table, is an alternative to traditional gouging that saves time and money.

The high performances of CEA's plasma cutting machine

The previously mentioned SK and SKM are the torches for plasma cutting machines designed by CEA for perfect control while working, and they ensure greater thermal energy.

The Back Striking technology in SK25 - SK65 torches makes ignition of the pilot arc precise and increases the life of the consumables.

The HPC (High Performance Cutting) technology increases the speed and quantity of air, concentrating the plasma even more, and stabilizes the arc. This system is standard in manual torches SK75, SK125, SK165 and those for automated plasma cutting, SKM75, SKM125. CEA’s large family of torches also includes the new LONG TORCH SKM165XL designed to work with greater ease and speed when needing a significant distance between the operator and the cutting area (e.g. Low-cost dismantling of metal structures, such as cars, containers, etc.).

These and much more are the features that make CEA’s Shark plasma cutting systems the perfect machines for professional work.

{{cta('c9819577-65d8-4853-80d0-e1a00c4511b7','justifycenter')}}