Robotic welding systems: CEA has the right solution

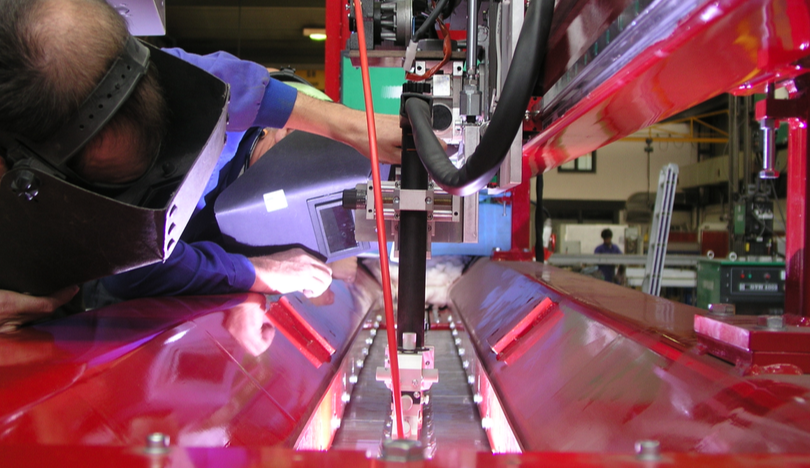

All the indications of industry 4.0 highlight the huge advantages brought by automation in factories, and therefore the great benefits of robotic welding systems.

The team of engineers at CEA, along with affiliate TECNOROBOT, have studied and created the line of machines for automation and robotics that enable companies to make a significant technological leap forward. This work has led to the creation of a comprehensive and reliable robotics line that each customer can integrate into new or already-existing systems in the best way possible.

In the CEA Automation Line there are systems for robotic welding systems that can perform the following functions:

- Automatic TIG welding machine

- Automatic MIG – MAG welding machine

- Pulsed MIG and TIG welding machine

If you want a FREE DEMO of our products or need some information click here! We're at your service!

Robotic welding systems: Digitech VP2 for welding in industry 4.0

Digitech VP2 is a synergic multiprocess system created by CEA to offer a smart solution to those who need to upgrade the technology at their factory, just as industry 4.0 recommends.

Indeed, this type of machine is compatible with the main welding robots on the market, so it can be very flexibly used in both new-design systems and in already-existing systems as retrofits for the latter.

Specifically, Digitech VP2 is the perfect solution for those situations where there is a need for the heart of the machine to be in one location, with minimal footprint, and the wire feeder in another (e.g. directly next to the torch).

READ ALSO: "Industry 4.0 applications: Digitech VP2"

The vision.ARC2 software enables taking advantage of the special processes that further improve the performance of the weld:

- PIPE for precise MIG MAG welding of pipes during the first root pass

- COLD lowers the heat input for welding thin sections

- ULTRASPEED increases welding speed

- POWER for welding medium/thick sections with greater penetration

- PULSE-UP designed for vertical-up welds

- PULSE-RUN increases pulsed welding speed

- PULSE-POWER for pulsed welding of medium/thick sections with greater penetration

Robocase: a technological heart guiding robots in robotic welding systems

Robocase is the synergic inverter generator created by CEA exclusively for MIG/MAG – MIG PULSE – DUAL-PULSE MIG robot welding.

The technology added to this machine is aided by that of Digitech VP2. Robocase has a technological heart enclosed in minimal dimensions and contains the very best CEA can offer, both in terms of hardware and software.

It’s perfect for those situations where all machine functions (welding, wire feeding, maintenance, cooling) need to be in just one location.

{% video_player "embed_player" overrideable=False, type='scriptV4', hide_playlist=True, viral_sharing=False, embed_button=False, width='317', height='564', player_id='9000364759', style='' %}

This generator is fully compatible with major robot manufacturers. As standard, Robocase has the EtherNet/IP digital interface, and fieldbus interfaces such as EtherNet/IP, DeviceNet and ProfiNet can be installed.

Robotcase can also use the special welding processes previously described for Digitech VP2.

READ ALSO: "Robotic welding: 5 good reasons to buy high tech welding machines"

MATRIX and ROBOMAT 1 for automated TIG welding

The Matrix range identified with the letter “R” consists of two types of three-phase generators (Matrix AC/DC-R and Matrix HF-R) that can be very easily connected to automatic systems for TIG welding.

Through the Robomat 1 interface, the machine can control all start/stop signals and manage the main welding parameters.

{{cta('c9819577-65d8-4853-80d0-e1a00c4511b7','justifycenter')}}