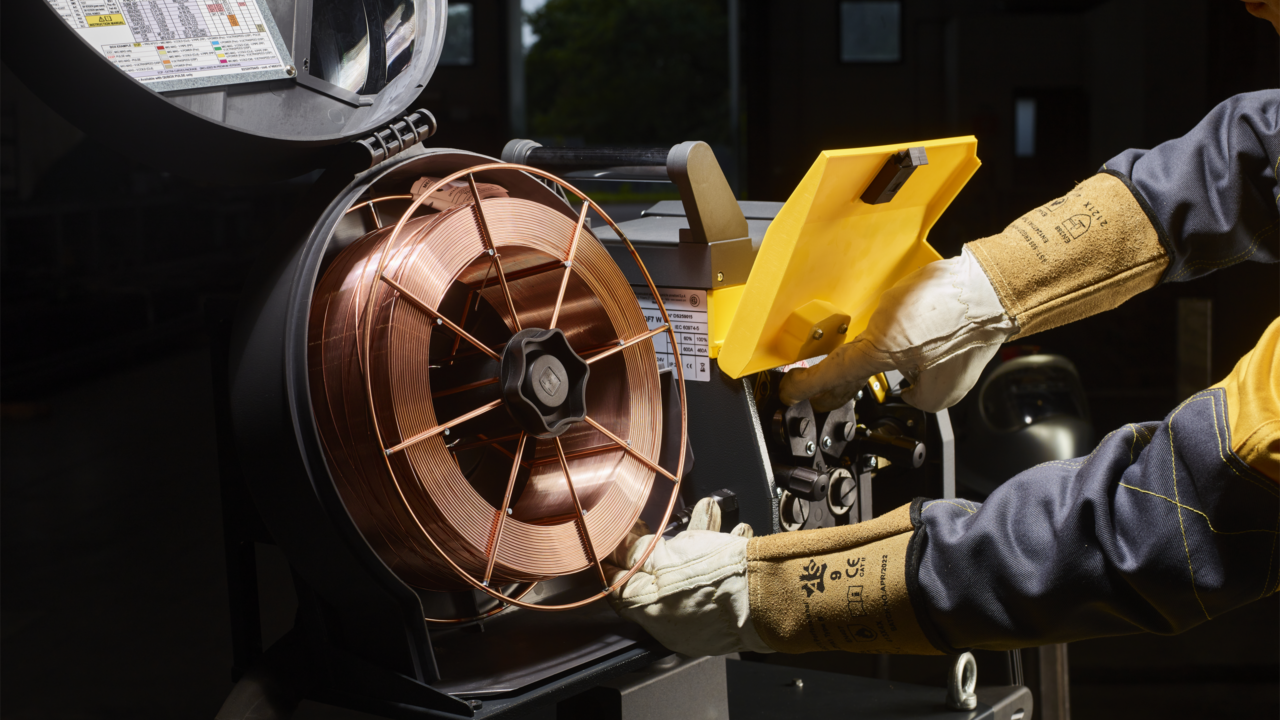

Wire Feeder MF 4 Hybrid Synergic 4 rolls (Ø: 1,0 / 1,2) Air cooled version

"*" indicates required fields

These power sources represent the best choice in all industrial fields for any qualified applications, such as medium and large fabrication work, shipyards and steel erection.

MAXIQ represents the logic evolution of the conventional step adjustment MIG equipment. It’s realized with a modern inverter integrated into a sturdy metallic structure and it’s managed by a simple and innovative digital control which will always grant high Quality welding performances.

MAXIQ keeps the adjustment simplicity of the conventional MIG equipment. Using only two knobs to set Voltage and Wire Speed, it offers the pleasure to set welding parameters as wished; with MAXIQ you never need any pre-selected synergic programs for setting the parameters on your behalf.

Wire Feeder MF 4 Hybrid Synergic 4 rolls (Ø: 1,0 / 1,2) Air cooled version

Wire Feeder MF 4 W Hybrid Synergic 4 rolls (Ø: 1,0 / 1,2) Water cooled version

WK 4 standard wheels kit

WK 2 extra-large wheel kit

HK 1 Hanging Kit for wire feeder

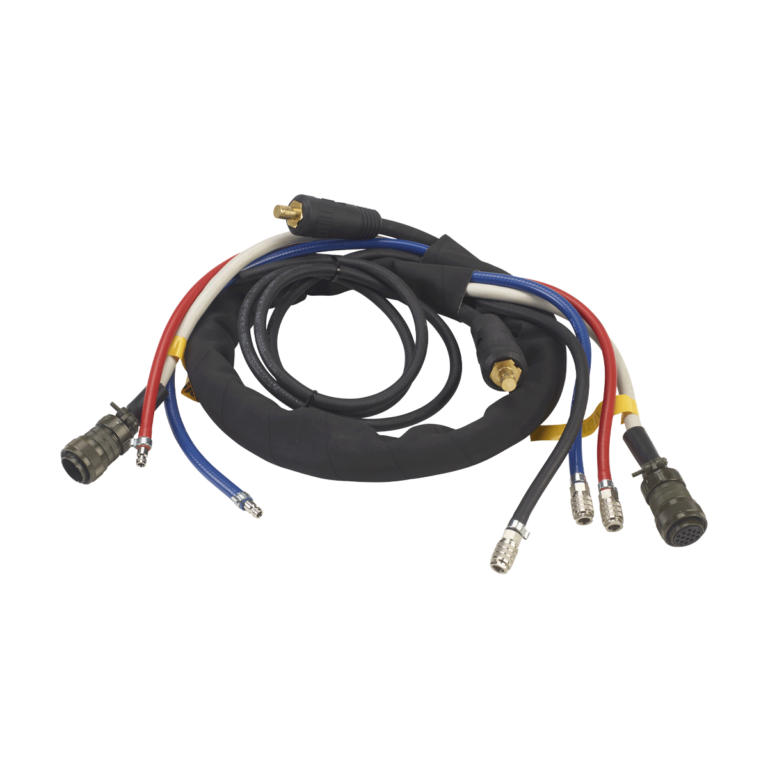

1,2 m Air cooled Interconnecting cable Power source-Wire feeder

4 m Air cooled Interconnecting cable Power source-Wire feeder

10 m Air cooled Interconnecting cable Power source-Wire feeder

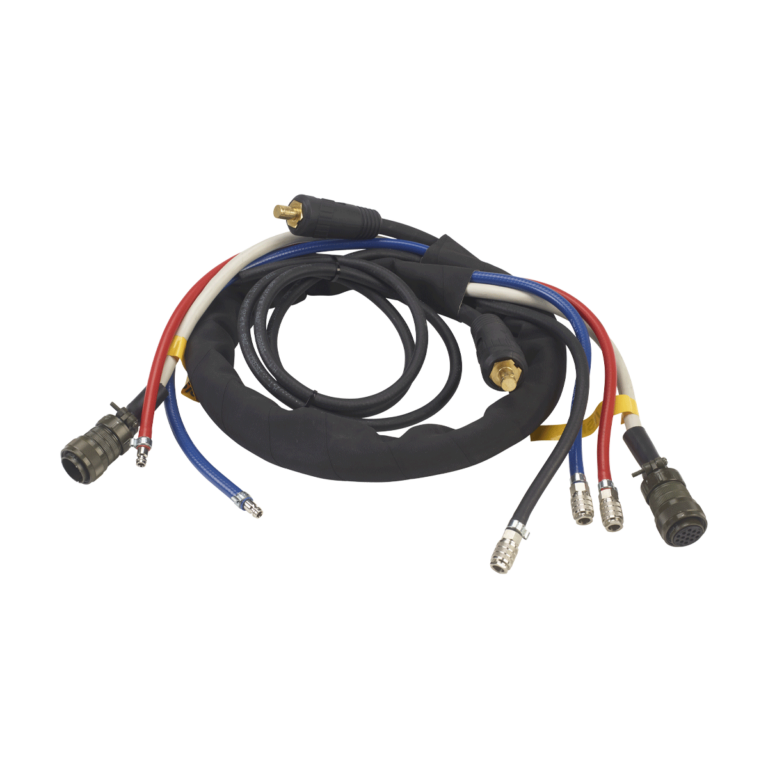

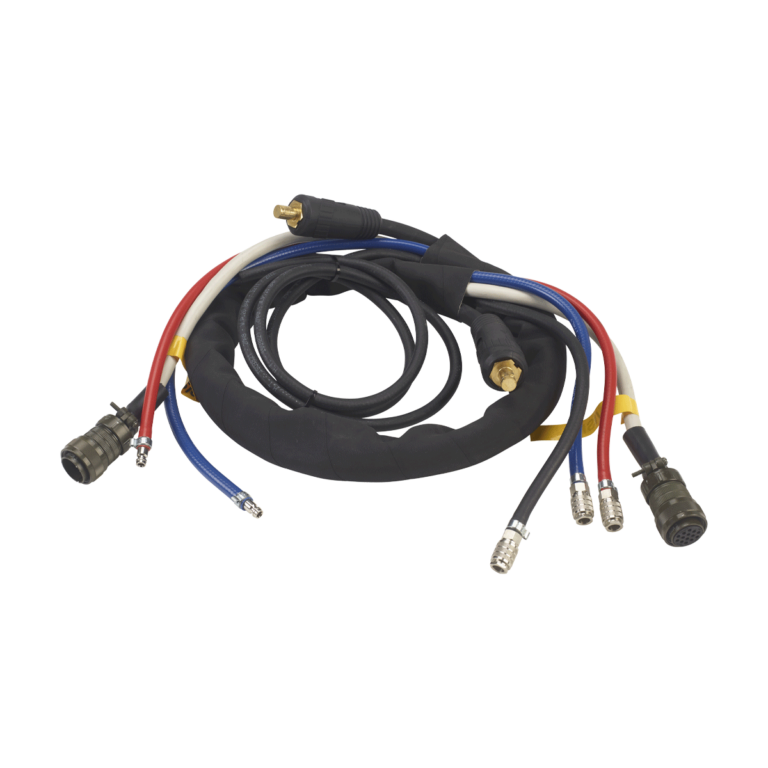

1,2 m Water cooled Interconnecting cable Power source-Wire feeder

4 m Water cooled Interconnecting cable Power source-Wire feeder

10 m Water cooled Interconnecting cable Power source-Wire feeder

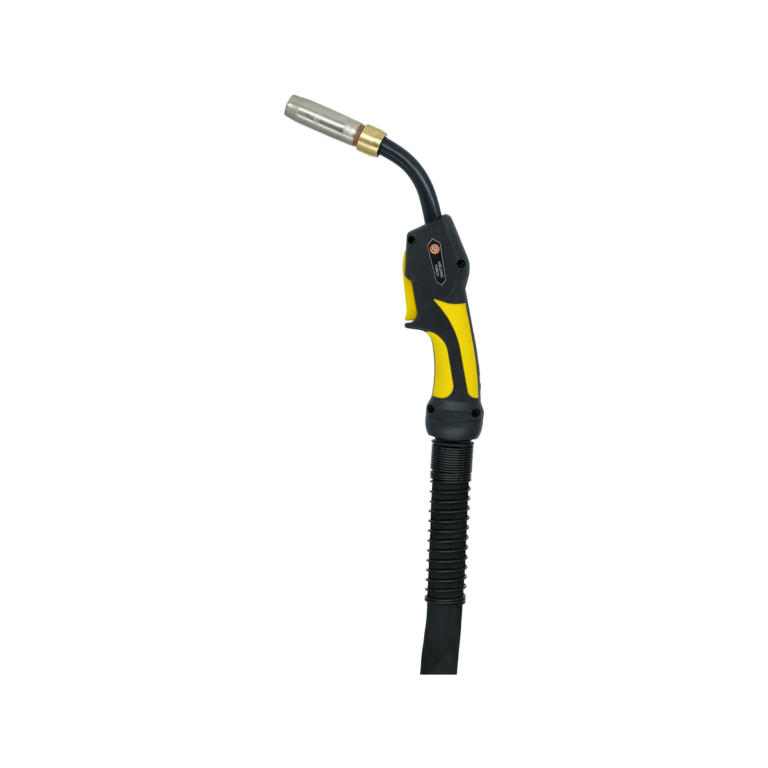

CEA Torch CX 353/4 4 m wire Ø 0.8÷1.2 CO2 340A @60% / Mix 290A @60%

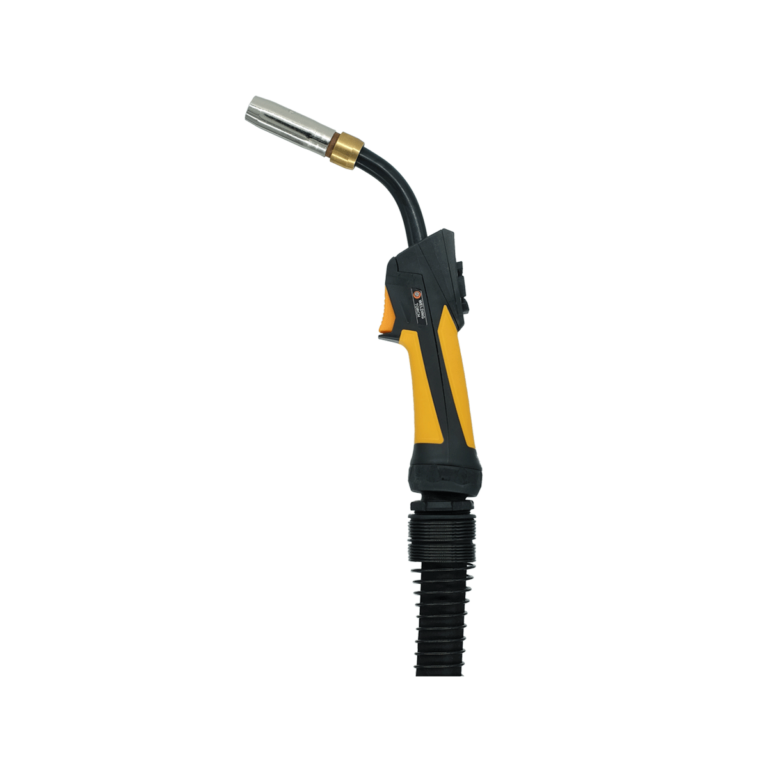

CEA Torch CX 451/4 4 m wire Ø 0.8÷1.6 CO2 400A @60% / Mix 300A @60%

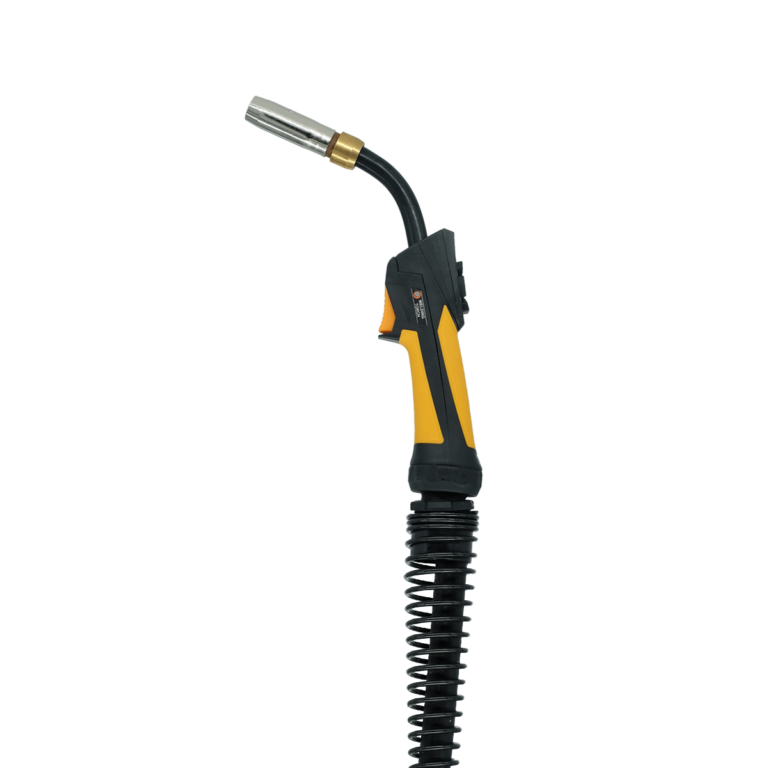

CEA Torch CXH 302/4 4 m wire Ø 0.8÷1.2 water cooled CO2 300A @100% / Mix 250A @100%

CEA Torch CXH 402/4 4 m wire Ø 0.8÷1.6 water cooled CO2 500A @100% / Mix 450A @100%

CEA Torch CXH 302/4 Up/Down-17p 4m – wire: Ø 0,8÷1.2 – CO2 300A @100% / Mix 250A @100%

CEA Torch CX 353/4 Up/Down-17p 4m – wire: Ø 0,8÷1.2 – CO2 340A @60% / Mix 290A @60%

CEA Torch CXH 402/4 Up/Down-17p 4m – wire: Ø 0,8÷1.6 – CO2 500A @ 100% / Mix 450A @100%

CEA Digitorch DXH 302/4-17p 4m – wire: Ø 0,8÷1.2 – CO2 300A @100% / Mix 250A @100%

CEA Digitorch DX 353/4-17p 4m – wire: Ø 0,8÷1.2 – CO2 340A @60% / Mix 290A @60%

CEA Digitorch DXH 402/4-17p 4m – wire: Ø 0,8÷1.6 – CO2 500A @100% / Mix 450A @100%

Push Pull Synchronizer PC Board KIT 24 / 42 V (to be ordered with the Push pull torch)

50 mm² / 4 m Ground cable with clamp

70 mm² / 4 m Ground cable with clamp

Cea CL-1100 cooling liquid – 5 l Tank

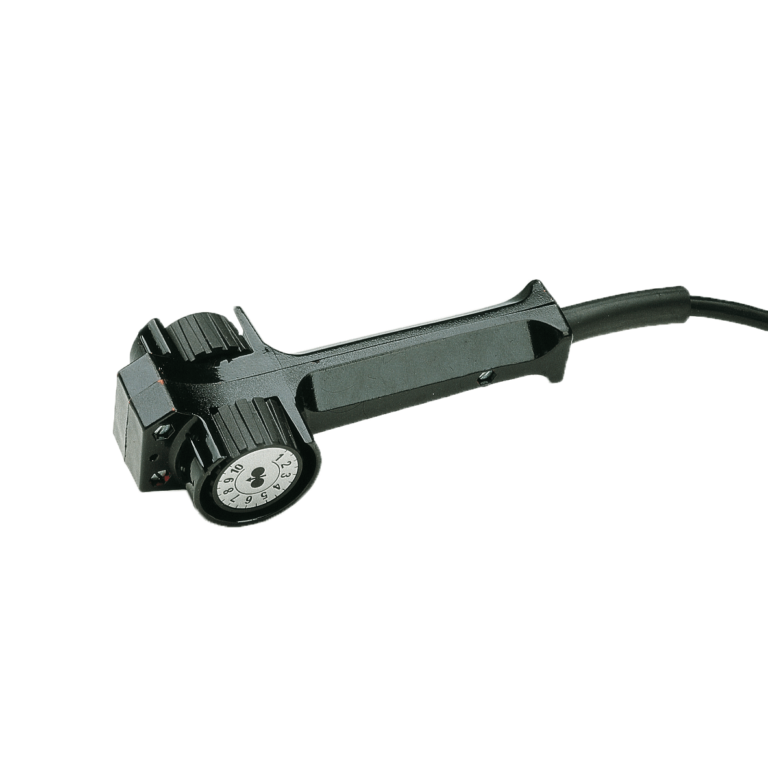

RC 178 remote control with 5 m cable

Cable winding kit (Maxi I/Maxiq/Qubox)