Transport Trolley CT 10

"*" indicates required fields

Powerful, compact and light MATRIX E are high performing and technologically advanced MMA power sources. MATRIX E power sources, are recommended for highest standard applications with any electrode.

Suitable to be used in shipyards, steel construction, pipe welding and maintenance, MATRIX E ensure an extraordinary stability of the welding parameters and their “fast dynamic characteristic” enables to achieve quality results even with the most difficult cellulosic and basic electrodes, and also in TIG with “Lift” mode arc striking.

Thanks to PFC the single phase MATRIX 2200 E optimizes the amount of energy consumption by allowing the use of this powerful power source with 16 A fuse mains and power generator sets.

Transport Trolley CT 10

Roll bar protection kit

CB 2 Carrying Belt Kit

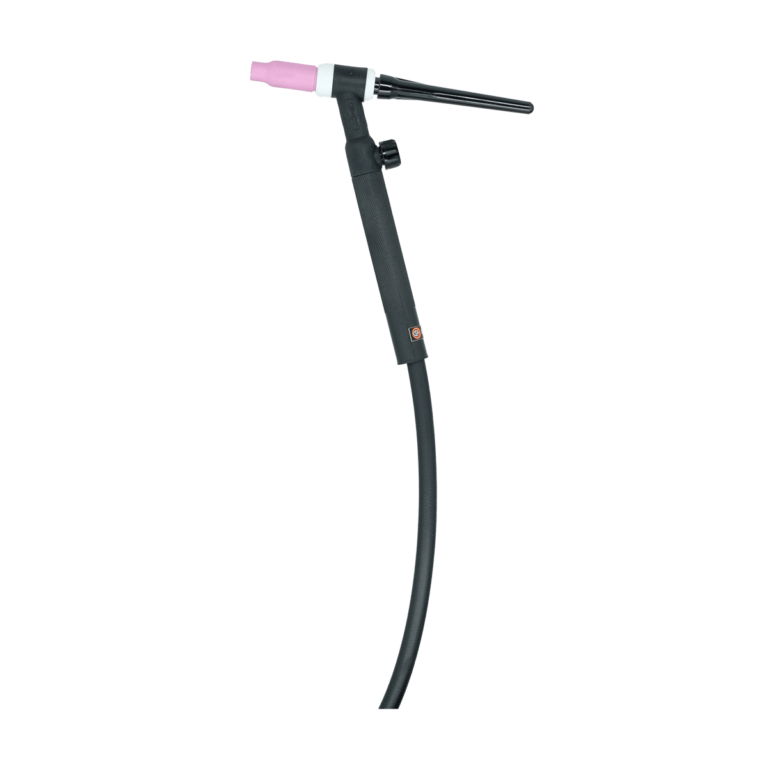

CEA Torch RTX 17.4 4 m – 140 A 35%

CEA Torch RTX 26.4 4 m – 180 A 35%