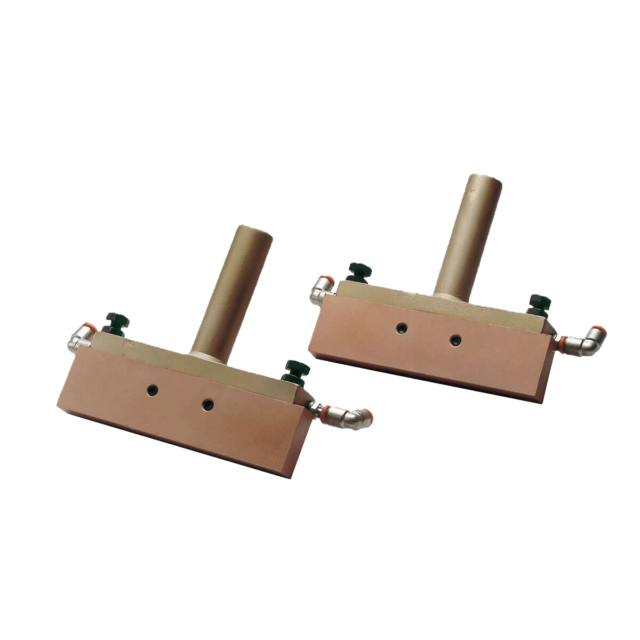

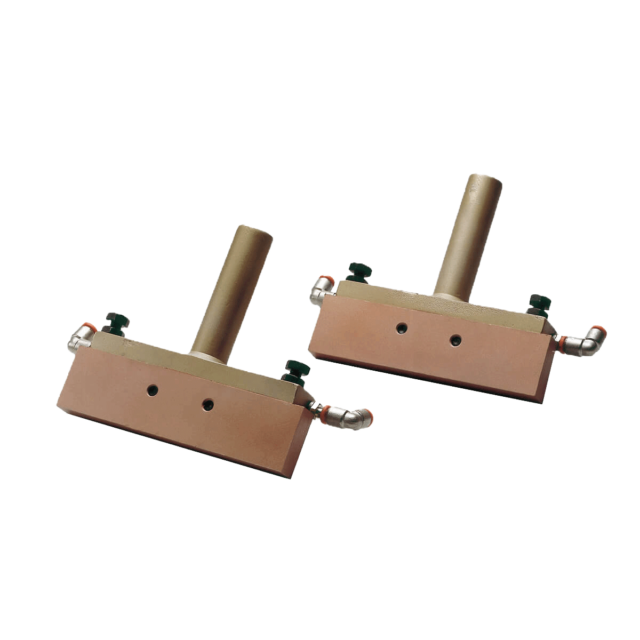

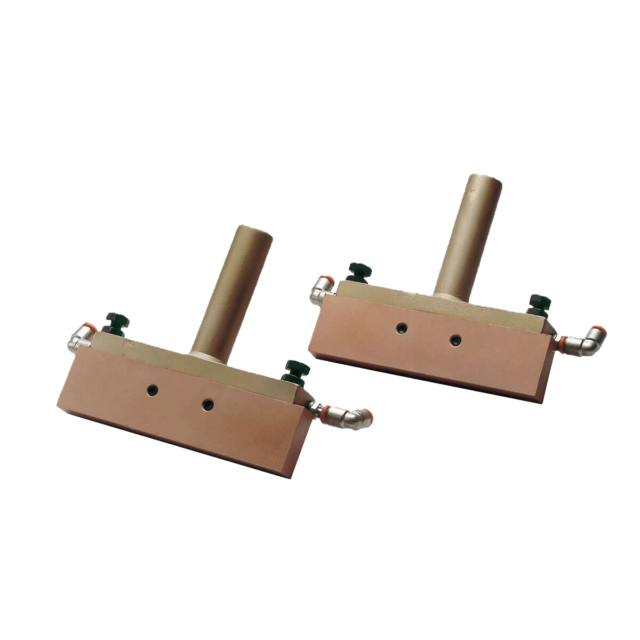

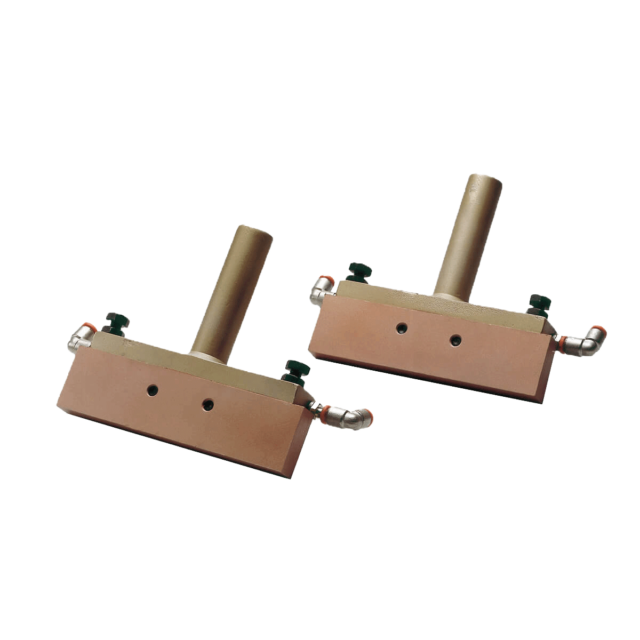

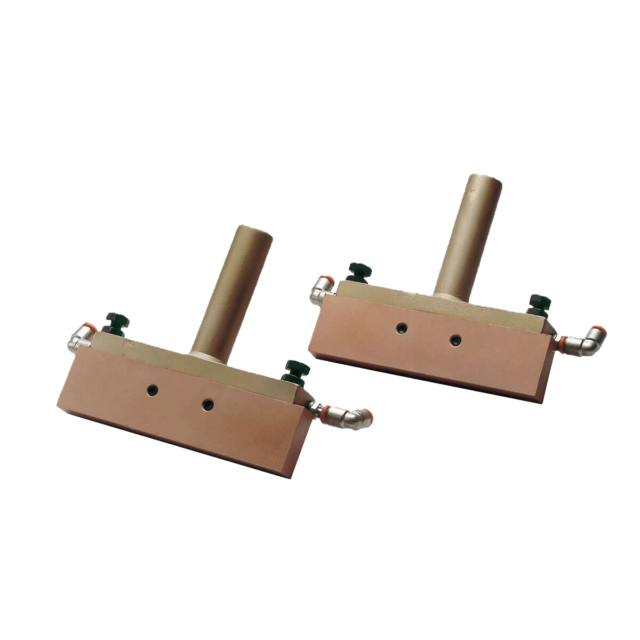

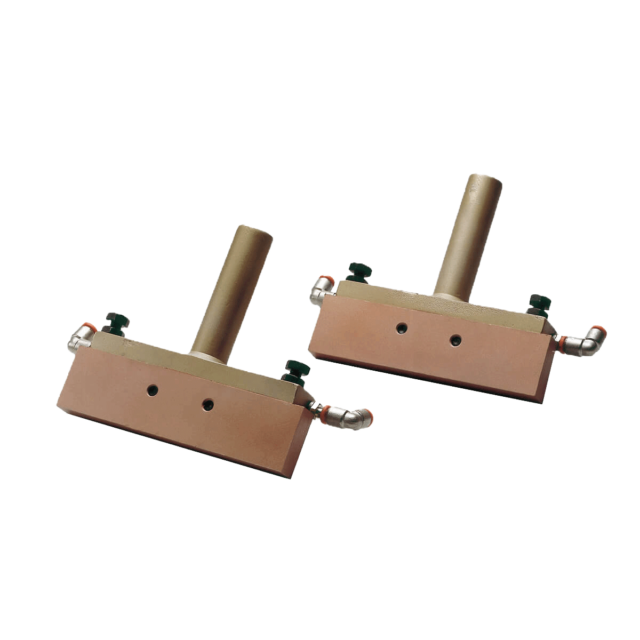

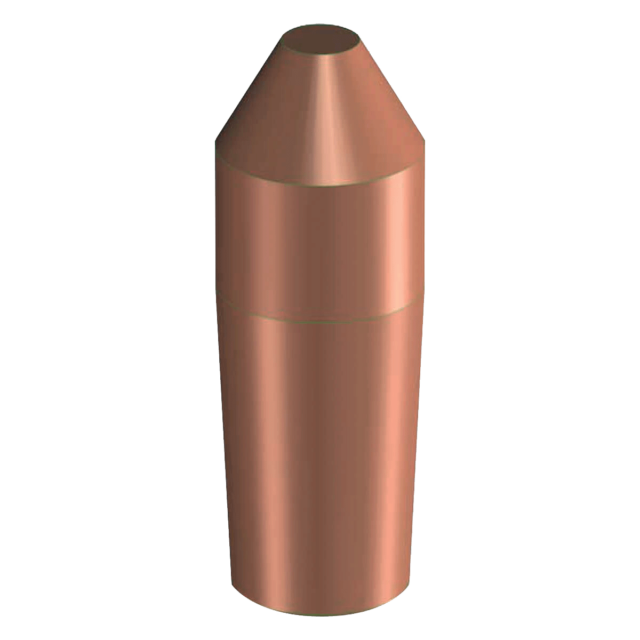

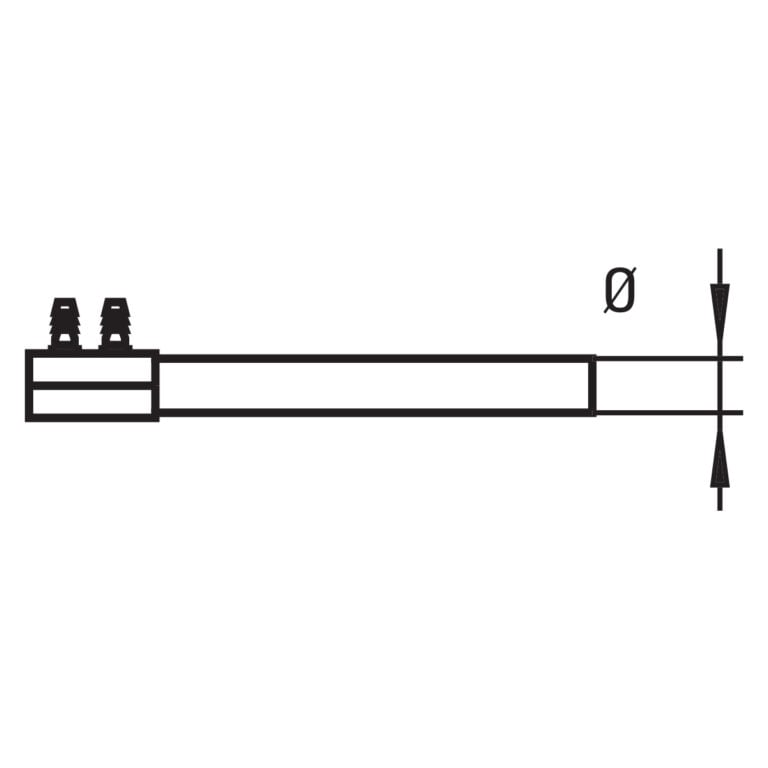

Set of pipe tips with electrodes depth 115 mm

"*" indicates required fields

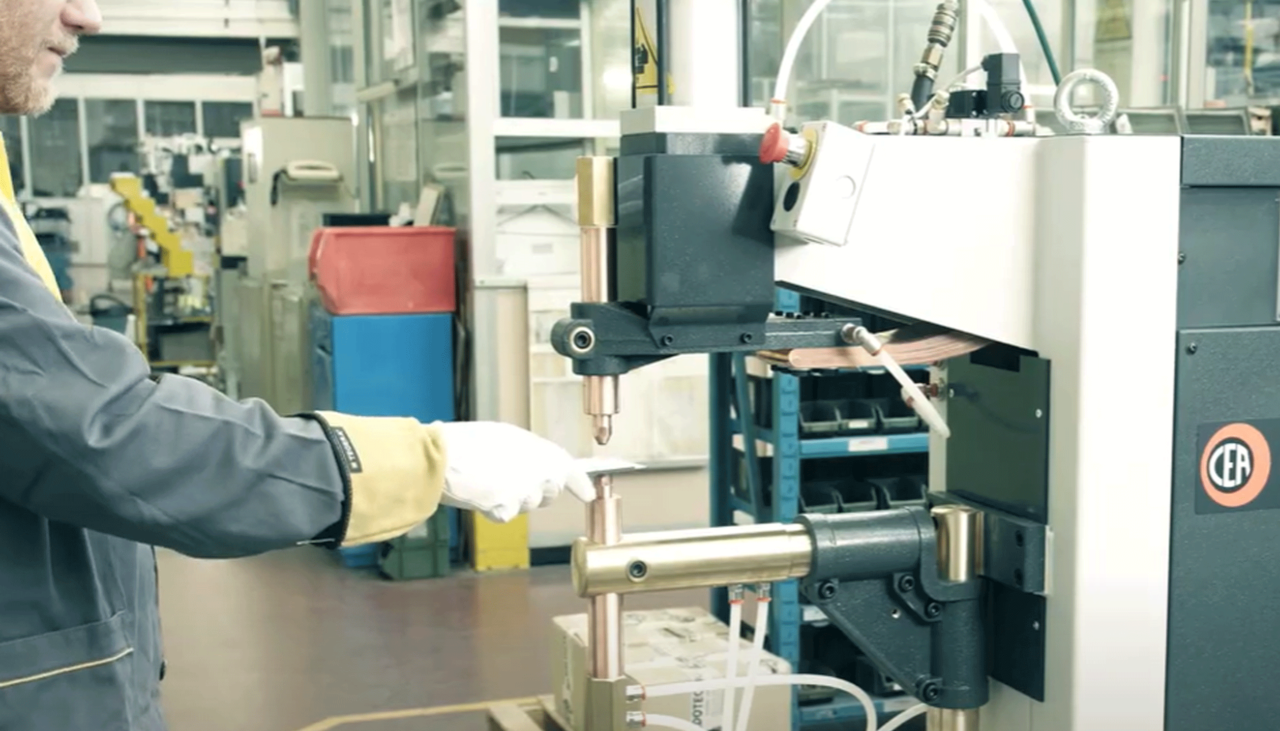

The MF range of medium-frequency inverter resistance welders is the ultimate answer to increasing demand for quality in resistance welding applications.

Constant current control, fast millisecond current regulation, high quality and perfect control of the energy transferred to the weld nugget are the main advantages versus traditional 50 Hz equipment.

MF models fully meet the toughest mass production industrial applications. Thanks to their features, they represent the ideal solution for resistance spot welding of thin thickness and of hardly weldable material, such as copper, brass, aluminium alloys, zinc plated and other coated steel.

MF represent a valid solution for anybody looking for all Medium Frequency benefits in spot and nut projection welder. MF models allow to monitor the whole welding process every 1 ms (1000 Hz).

The MF Inverter fully meets the mass production necessity. Thanks to their features, they are suitable for welding very thin thickness, metals hardly weldable such as copper, brass, aluminium alloys or zinc coated steels, etc., also whenever different metals have to be joined.

MF Inverter spot welders can be standard supplied in different sizes. Thanks to this wide range of solution it is possible to find the right solution at any necessity no metter how complicate is the task required.

Set of pipe tips with electrodes depth 115 mm

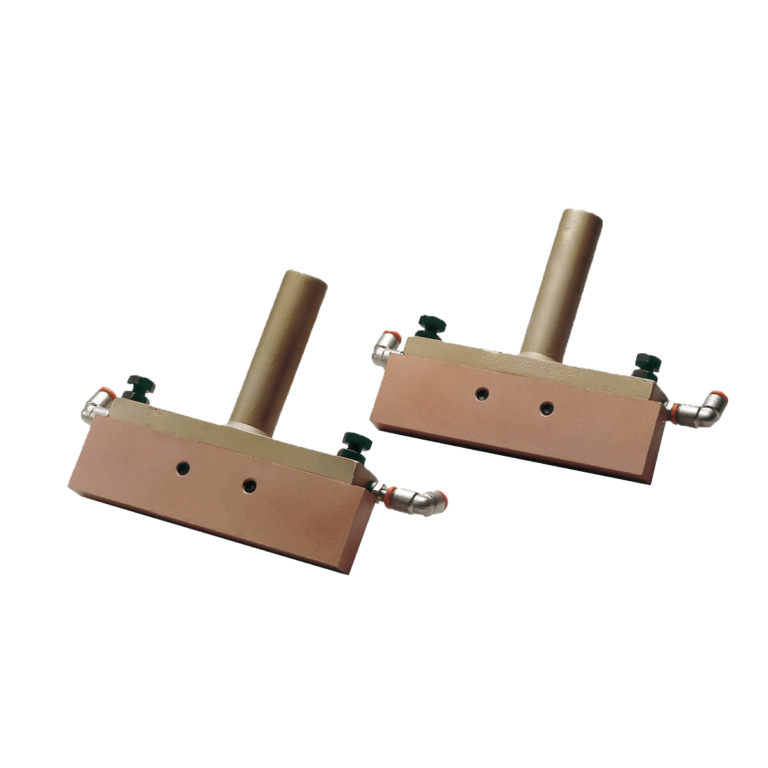

Set barholders with 200 mm bars

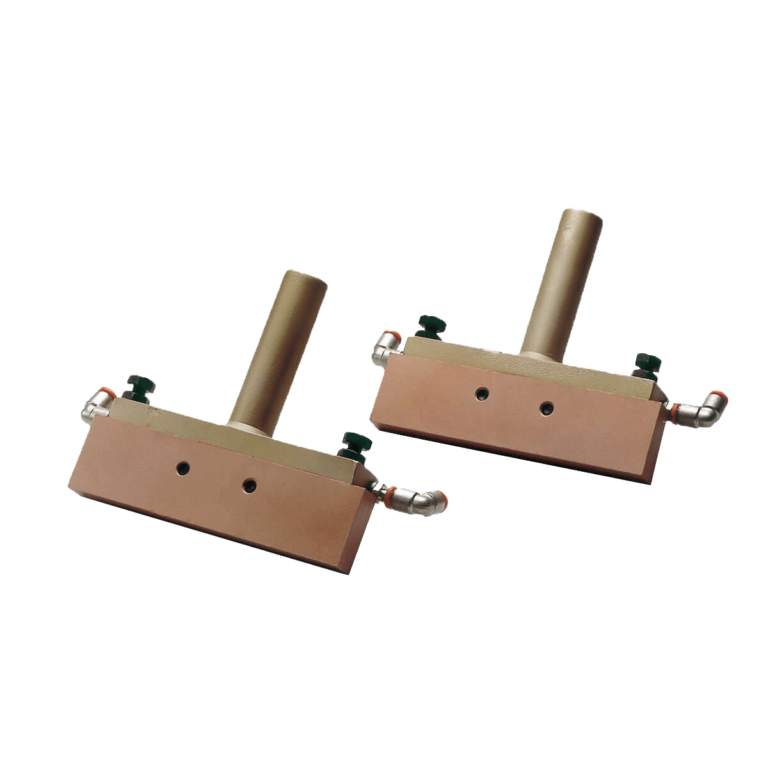

Set barholders with 400 mm bars

External safety concomitant push buttons unit

External safety concomitant push buttons unit

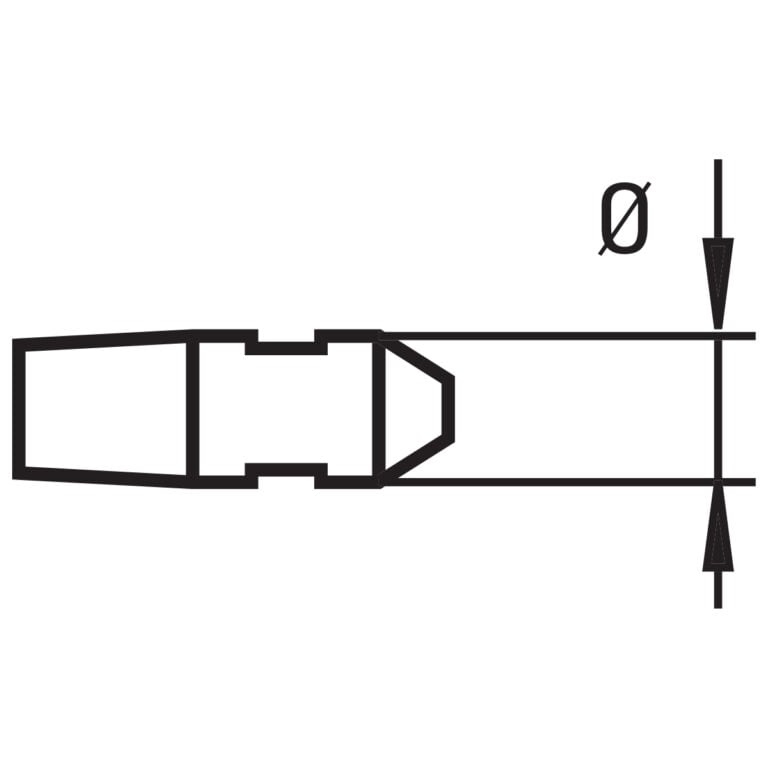

Set electrodeholders with electrodes

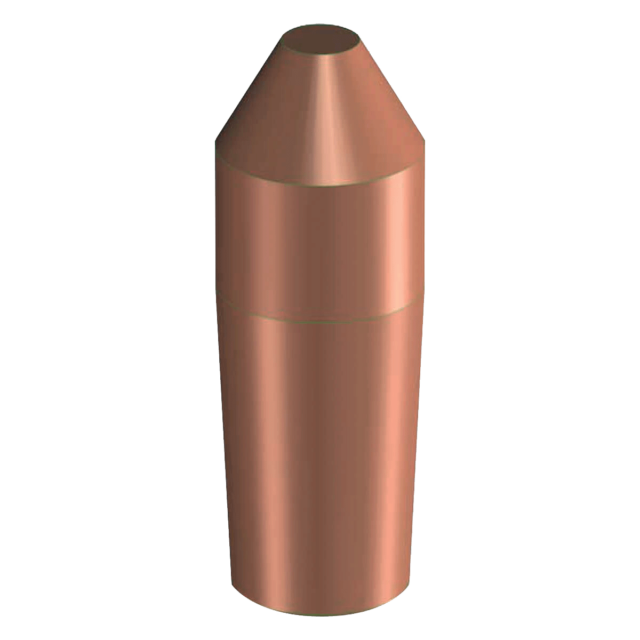

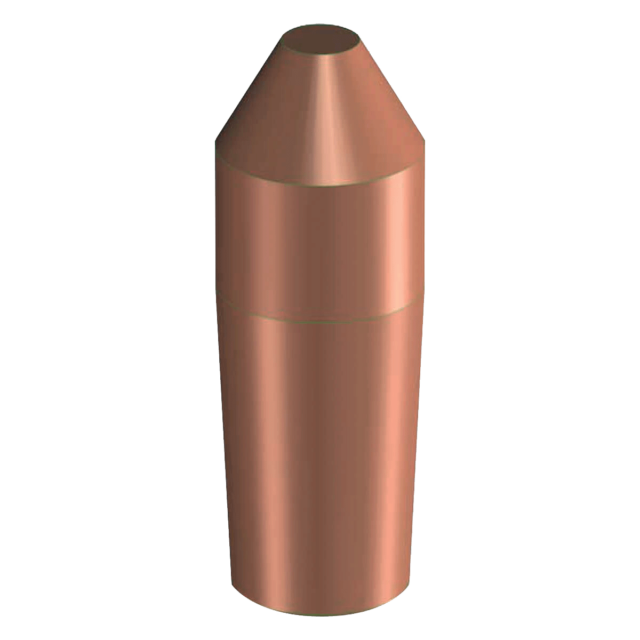

Set of 6 standard electrodes – Ø 19 mm

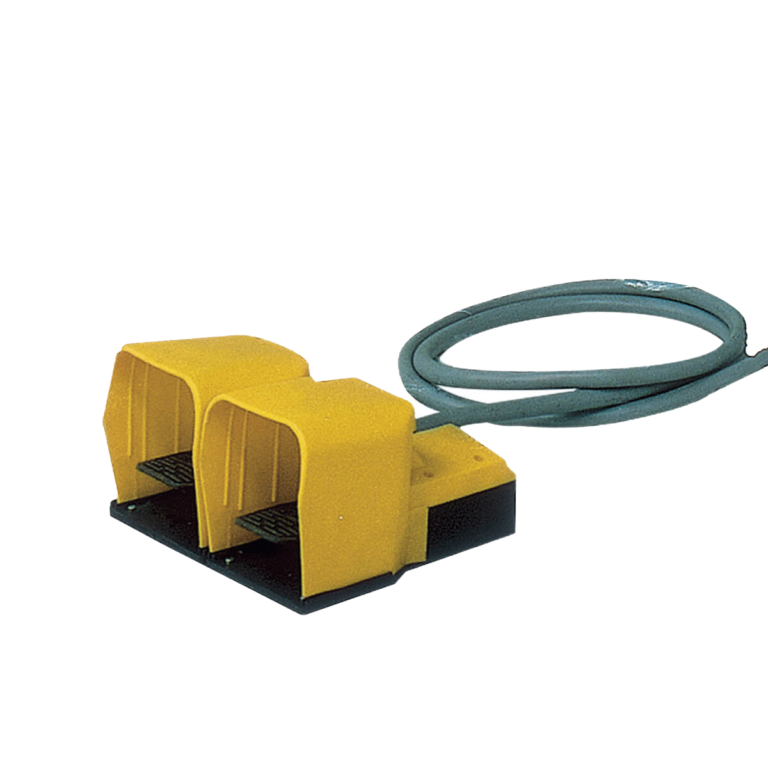

2 step pedal (1st step: squeeze, 2nd step: welding)

2 pedals (2 times – 2 welding currents)

| TECNICAL DATA | MF 1040 | MF 1041 | MF 100 | MF 160 | MF 200 | |

| Three Phase input 50/60Hz | V | 400 | 400 | 400 | 400 | 400 |

| Rated power at 50% | kVA | 40 | 40 | 100 | 160 | 200 |

| Fuse (delayed action) | A | 63 | 63 | 63 | 100 | 160 |

| Open Circuit Voltage | V | 5,0 | 5,0 | 10 | 10 | 12 |

| Secondary short circuit current | kA | 22 | 22 | 28 | 45 | 55 |

| Max welding current | kA | 20 | 20 | 23 | 36 | 44 |

| Secondary thermal current at 100% | kA | 5,4 | 5,4 | 6,5 | 12,0 | 12,0 |

| Work stroke | mm | 65 | 65 | 100 | 100 | 100 |

| Electrode force at 600kPa (6bar) | daN | 470 | 470 | 900 | 1200 | 1800 |

| Dimensions (LxWxH) | mm | 1070 x 430 x 1520 | 1070 x 430 x 1520 | 1115 x 400 x 1650 | 1115 x 400 x 1650 | 1210 x 460 x 1800 |

| Weight | kg | 260 | 260 | 530 | 550 | 850 |

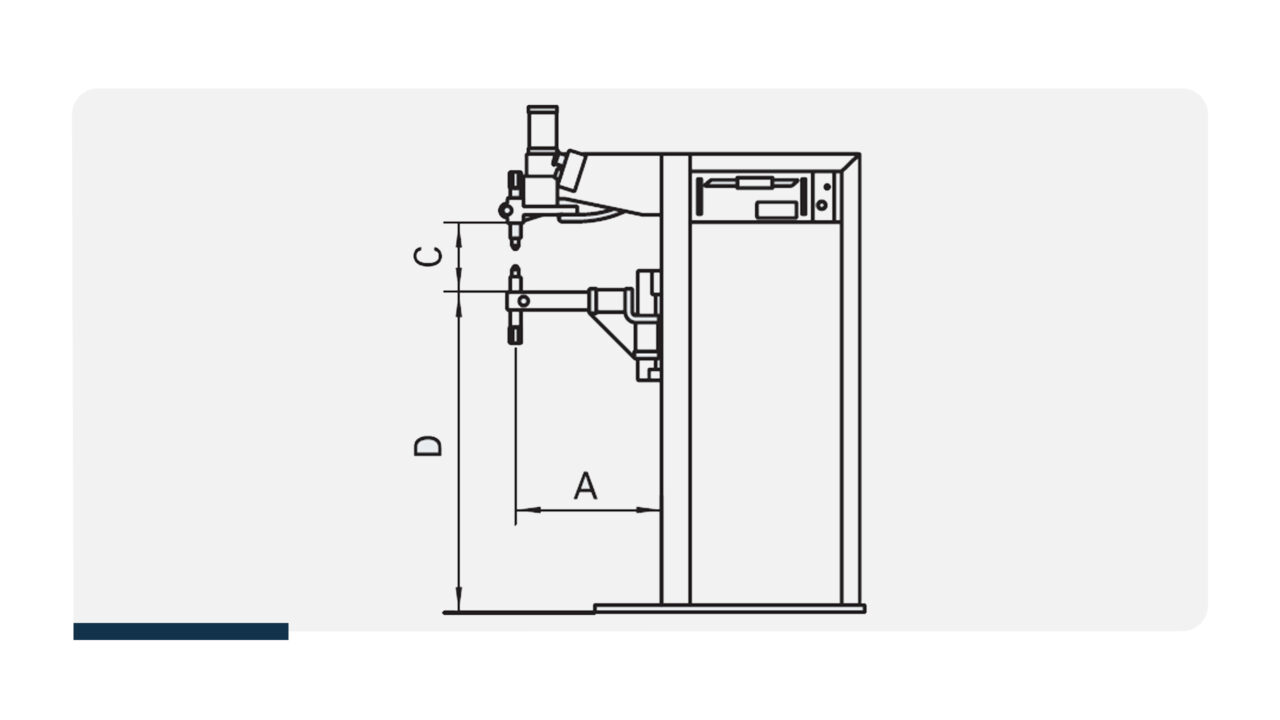

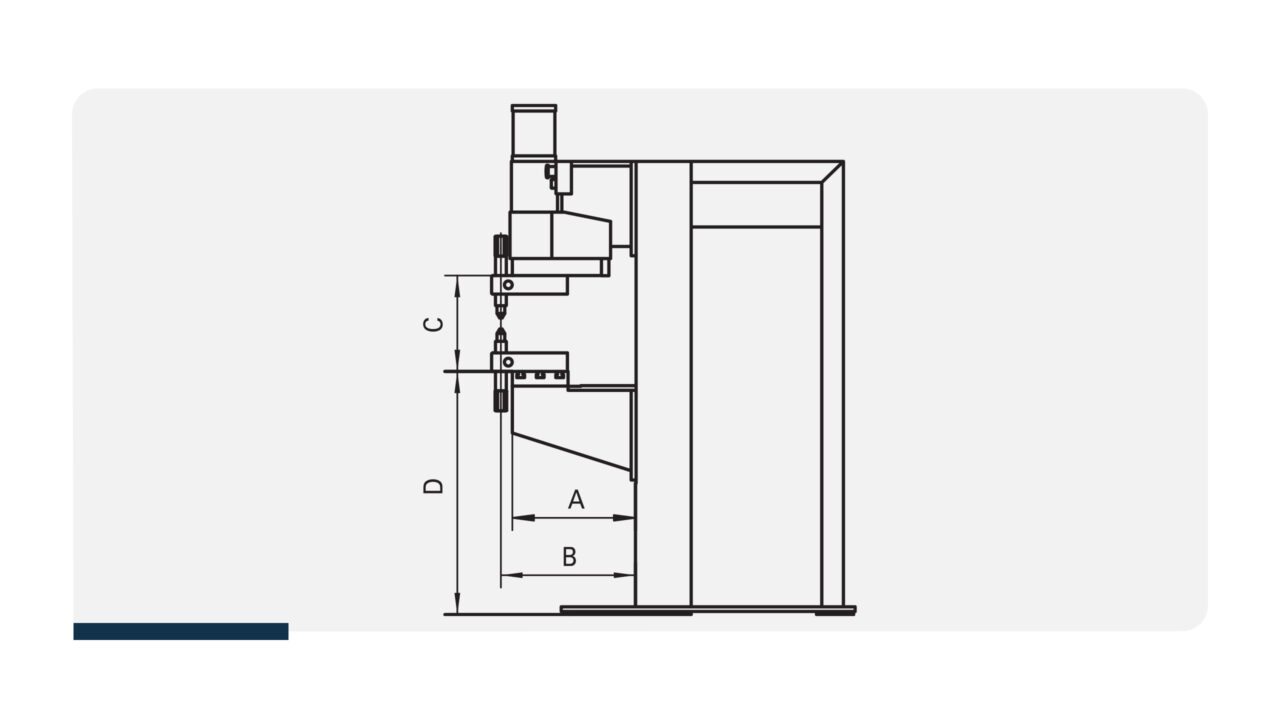

| MF 1040 | MF 1041 | ||

| A | mm | 435 | 435 |

| A (Optional) – MIN. | mm | 650 | 650 |

| A (Optional) – MAX. | mm | 750 | 750 |

| C – MIN. | mm | 180 | 180 |

| C – MAX. | mm | 510 | 510 |

| D – MIN. | mm | 615 | 615 |

| D – MAX. | mm | 945 | 945 |

|

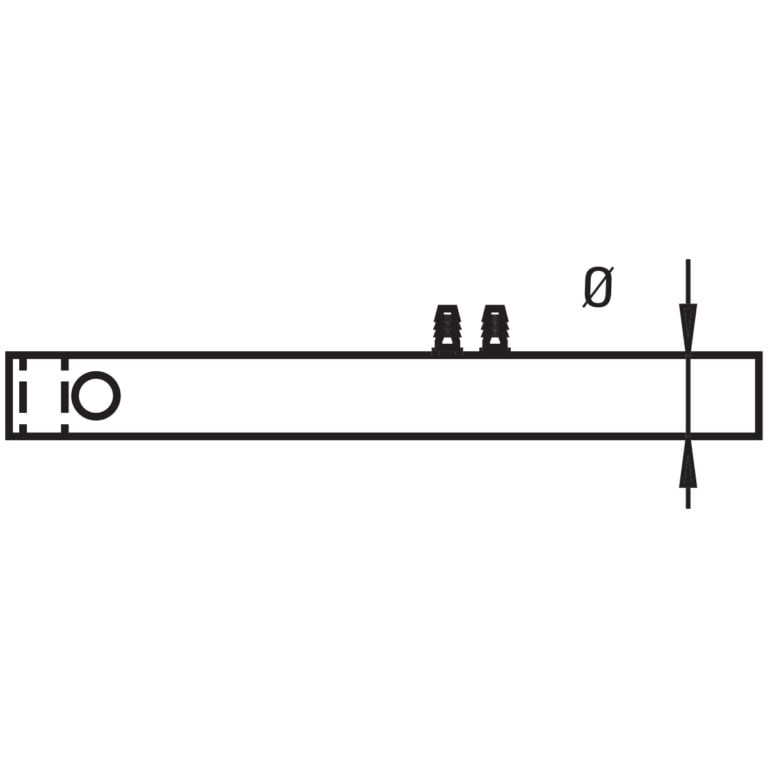

Ø mm | 60 | 60 |

|

Ø mm | 35 | 35 |

|

Ø mm | 19 | 19 |

| MF 100 | MF 160 | MF 200 | ||

| A | mm | 400 | 400 | 445 |

| A (opzionale) – MIN. | mm | 650 | 650 | 650 |

| B | mm | 445 | 445 | 490 |

| C – MIN. | mm | 145 | 145 | 200 |

| C – MAX. | mm | 300 | 300 | 330 |

| D – MIN. | mm | 800 | 800 | 865 |

| D – MAX. | mm | 955 | 955 | 995 |

| MF 100 | MF 160 | MF 200 | ||

| A | mm | 400 | 400 | 445 |

| A (opzionale) – MIN. | mm | 650 | 650 | 650 |

| B | mm | 445 | 445 | 490 |

| C – MIN. | mm | 145 | 145 | 200 |

| C – MAX. | mm | 300 | 300 | 330 |

| D – MIN. | mm | 800 | 800 | 865 |

| D – MAX. | mm | 955 | 955 | 995 |