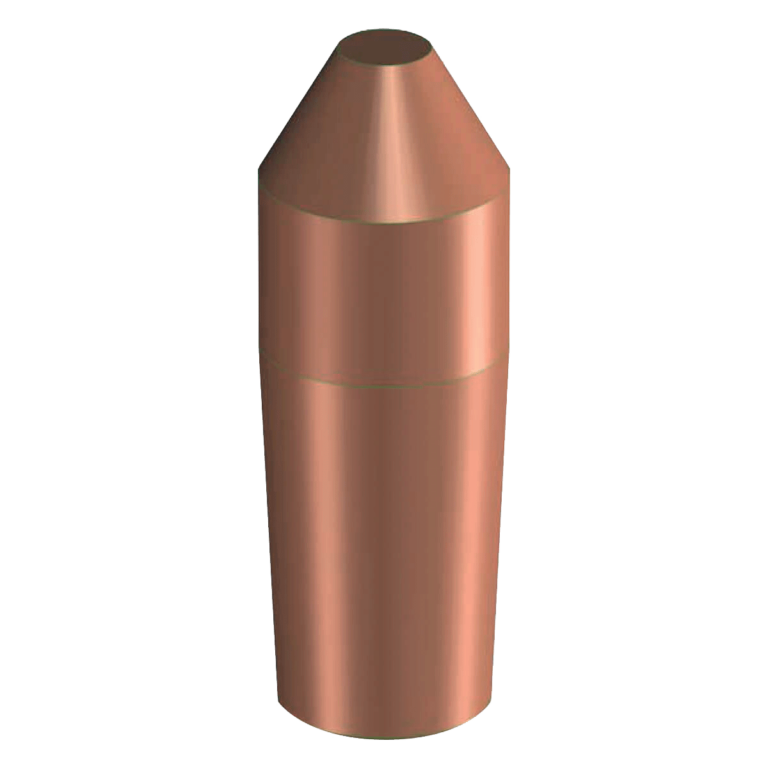

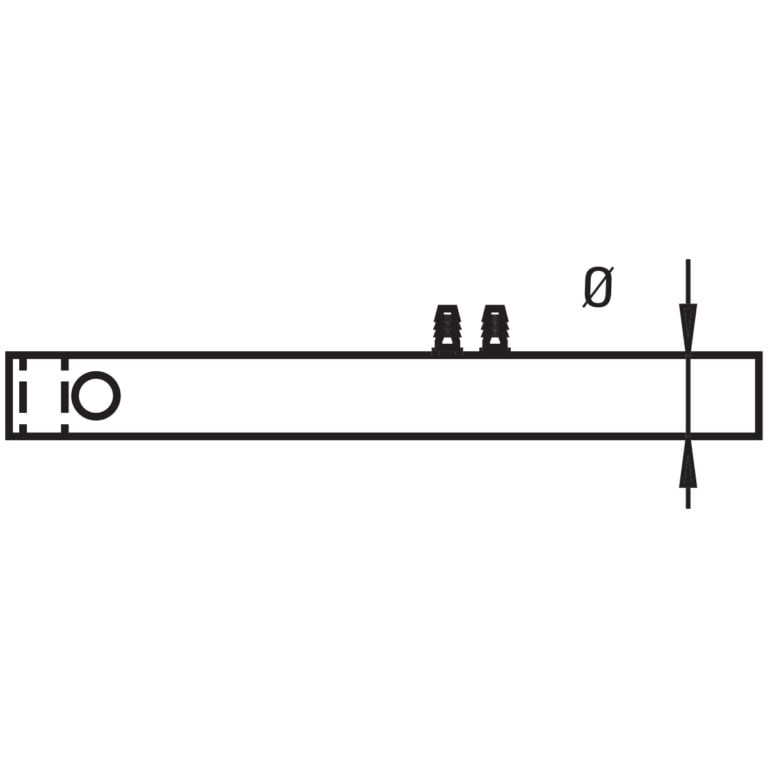

Set of pipe tips with electrodes depth 65 mm

"*" indicates required fields

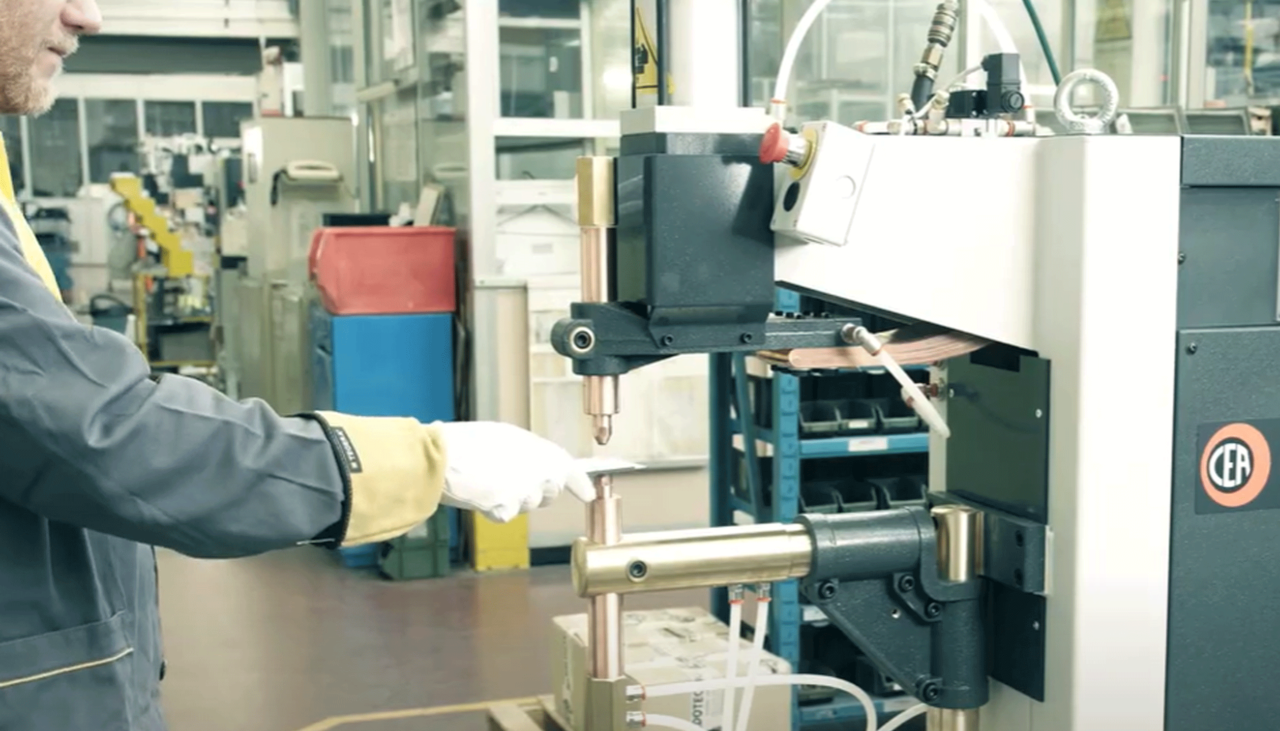

Particularly studied for spot welding, PPS model fully satisfy a wide range of the heaviest large production industrial applications. Equipped with microprocessor control, solenoid valve, upon request they can be fitted with safety concomitant side buttons and any special configurations.

PPS models, developed appositely for spot welding jobs, fully satisfy a wide range of the heaviest large production industrial applications. Equipped with a microprocessor control, upon request they can be supplied in special configurations or fitted with an optional safety concomitant push button external unit.

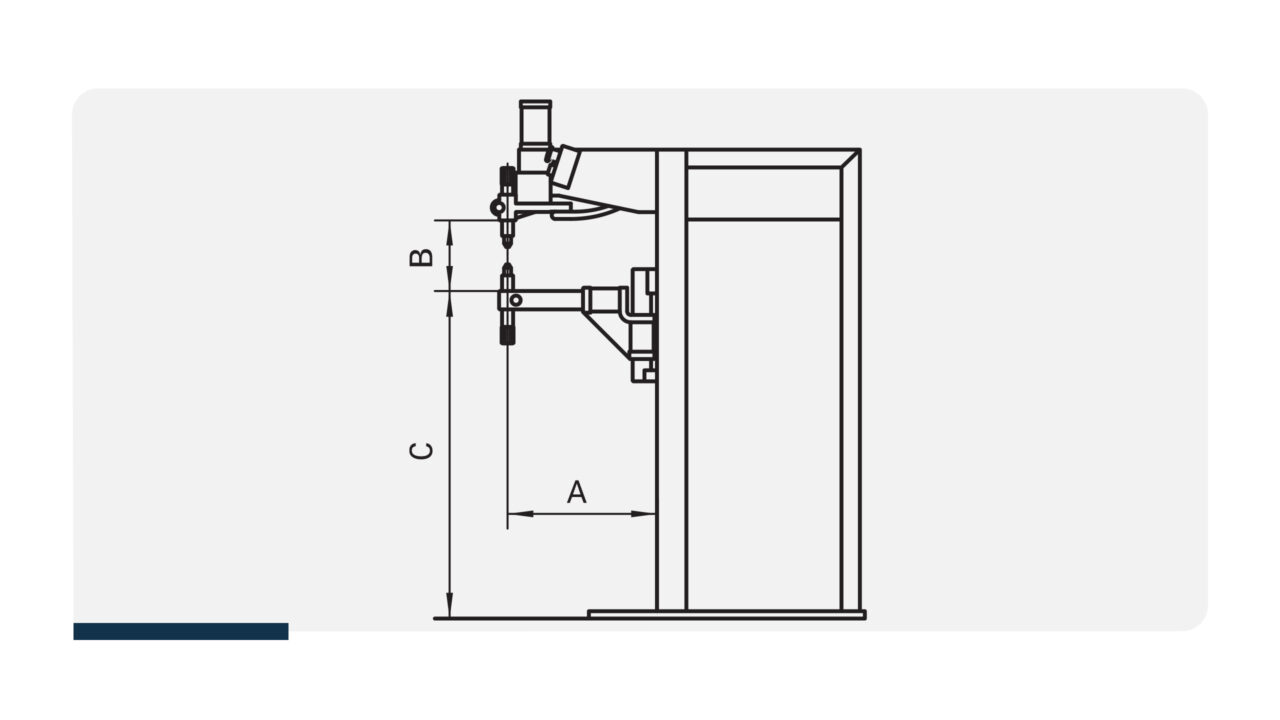

PPS 35 – 60

PPS 125

Set of pipe tips with electrodes depth 65 mm

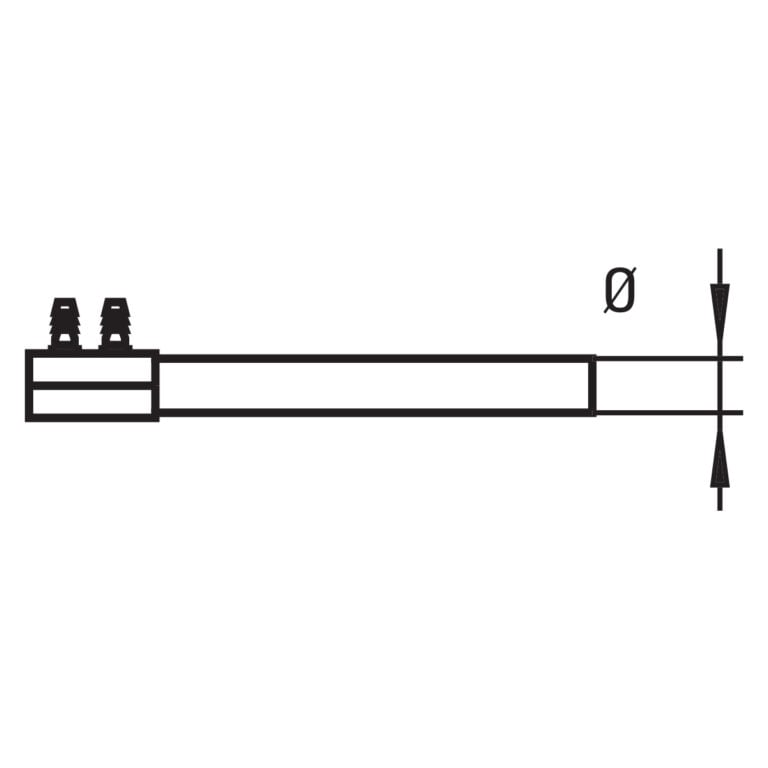

Set of pipe tips with electrodes depth 115 mm

External safety concomitant push buttons unit

Set electrodeholders with electrodes

Set electrodeholders with electrodes

Set electrodeholders with electrodes

Set of 6 standard electrodes – Ø 19 mm

Set of 6 standard electrodes – Ø 25 mm

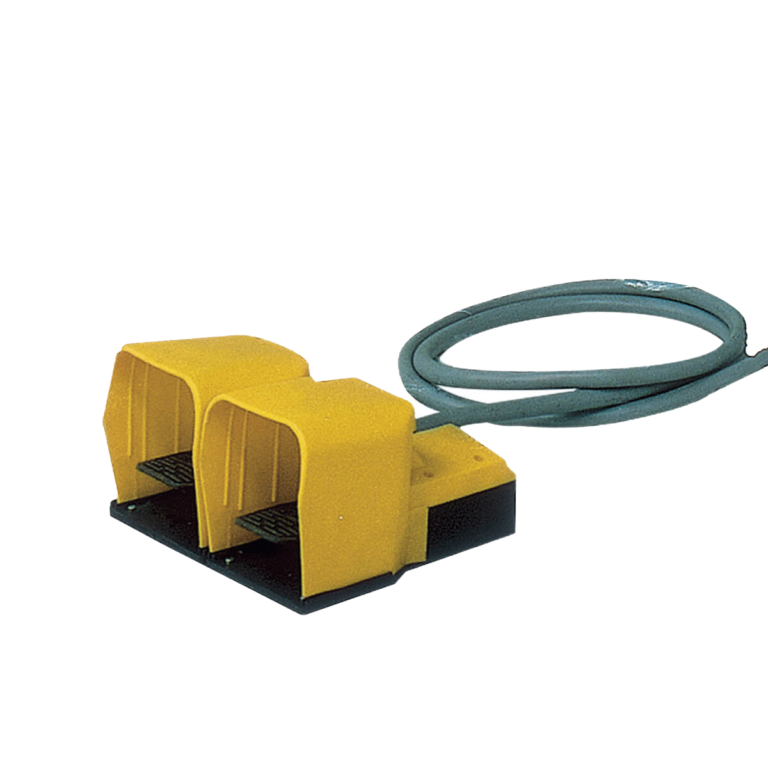

2 step pedal (1st step: squeeze, 2nd step: welding)

2 pedals (2 times – 2 welding currents)

| TECHNICAL DATA | PPS 35 | PPS 60 | PPS 125 | |

| Single phase input 50/60 Hz | V | 400 | 400 | 400 |

| Rated power at 50% | kVA | 35 | 60 | 125 |

| Max. welding power | kVA | 69 | 113 | 294 |

| Installed power | kVA | 20 | 38 | 80 |

| Fuse(delayed action) | A | 63 | 100 | 250 |

| Secondary voltage | V | 4,5 | 5,9 | 11,5 |

| Secondary short circuit current | kA | 19 | 24 | 32 |

| Max welding current | kA | 15,2 | 19,2 | 25,6 |

| Work stroke | mm | 85 | 65 | 100 |

| Electrode force at 600kPa (6bar) | daN | 300 | 470 | 900 |

| Water consumption at 300 kPa (3bar) | l/min | 7 | 7 | 8 |

| Dimensions (LxWxH) | mm | 1005 x 410 x 1425 | 1070 x 430 x 1520 | 1370 x 420 x 1750 |

| Weight | kg | 200 | 335 | 700 |

| PPS 35 | PPS 60 | PPS 125 | ||

| A | mm | 395 | 435 | 500 |

| A (Optional) | mm | – | 650 | 700 |

| B – MIN. | mm | 140 | 180 | 170 |

| B – MAX. | mm | 400 | 510 | 320 |

| C – MIN. | mm | 690 | 615 | 710 |

| C – MAX. | mm | 950 | 945 | 860 |

|

Ø mm | 50 | 60 | 90 |

|

Ø mm | 30 | 35 | 35 |