Water cooling equipment HR 22 230 V

"*" indicates required fields

MATRIX HF are highly technologically advanced TIG power sources with a complete and user friendly interface for the total control of all welding parameters.

MATRIX HF grant excellent TIG welding performances with mild and stainless steel, copper and its alloys and are suitable to be used for the toughest industrial applications and maintenance.

MATRIX HF offer excellent performances in MMA welding with the most difficult basic and cellulosic electrodes.

MATRIX 2200 HF optimizes the energy consumption with PFC device and is the ideal choice whenever power and portability are needed.

Water cooling equipment HR 22 230 V

Water cooling equipment HR 23 400 V

Cea CL-1100 cooling liquid – 5 l Tank

Trolley VT 101 with 2 rolls for power source, cooling equipment and cylinder

Trolley VT 200 for power source, HR 23 cooling equipment and cylinder

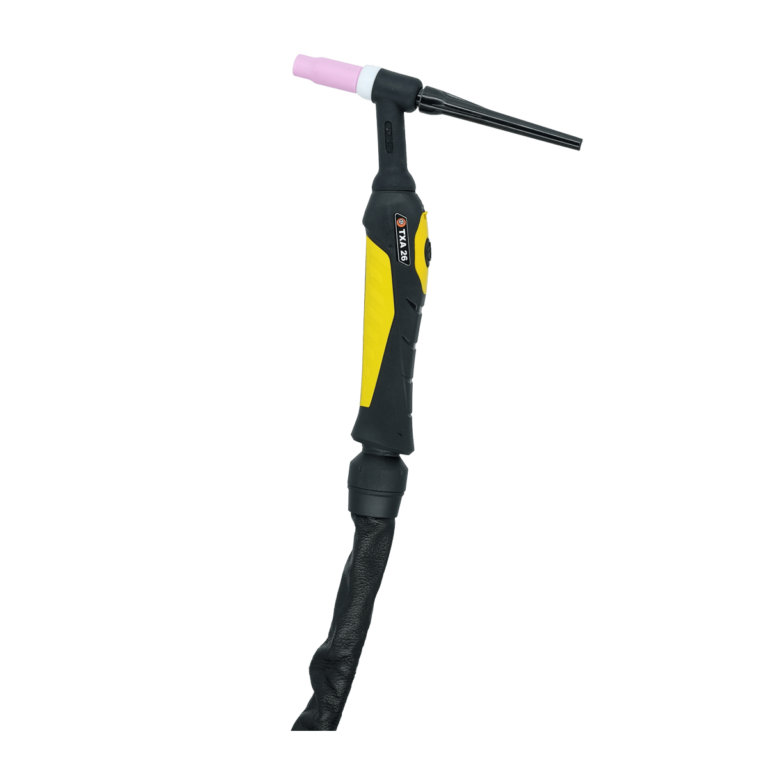

CEA Torch TXA 26.4 4 m – 250 A 60% (DC)

CEA Torch TXA 26.4 “UP/DOWN” 4 m – 250 A 60% (DC)

CEA Torch TXH 18.4 4 m – 320 A 100% (DC) – water cooled

CEA Torch TXH 18.4 “UP/DOWN” 4 m – 320 A 100% (DC) – water cooled

CEA Torch Mini TXH 20.4 4 m – 250 A 100% (DC) – water cooled

CEA Torch Mini TXH 20.4 “UP/DOWN” 4 m – 250 A 100% (DC) – water cooled

35 mm² / 4 m Ground cable with clamp

50 mm² / 4 m Ground cable with clamp

Reducer with flowmeter and 1 manometer

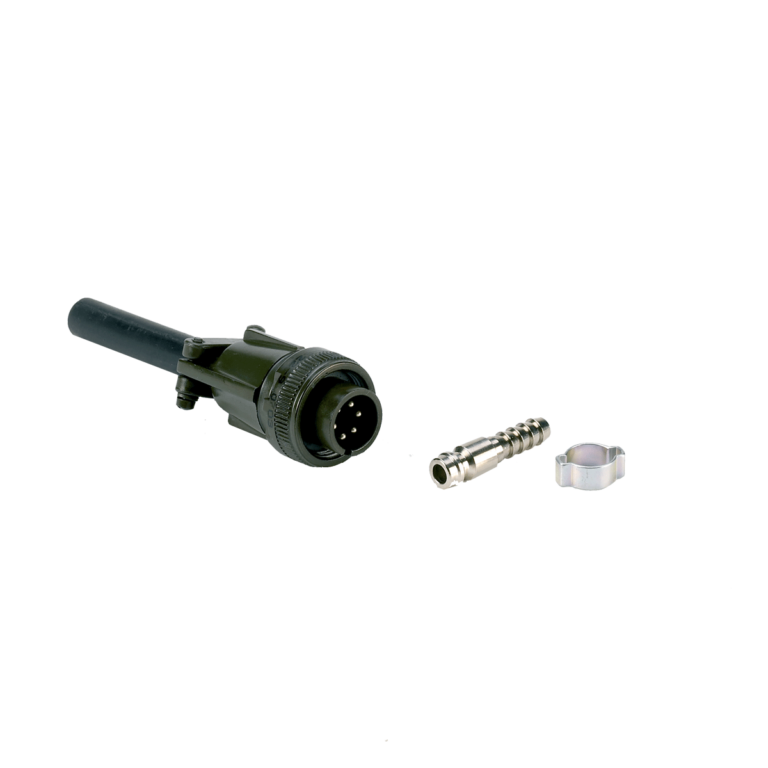

Adapter for simultaneous connection of Torch and PSR 7

A6 Connection kit for non-standard Torch